Arcmaster 401s power source, 03 tig (gtaw) basic welding technique – Tweco ArcMaster 401S User Manual

Page 50

ARCMASTER 401S POWER SOURCE

FAULT

CAUSE

REMEDY

7 Crack occurring in

weld metal soon

after solidification

commences

A Rigidity of joint.

A Redesign to relieve weld joint of severe stresses

or use crack resistance electrodes.

B Insufficient throat thick-

ness.

B Travel slightly slower to allow greater build up in

throat.

C Weld current is too high. C Decrease welding current.

Art: A-04973

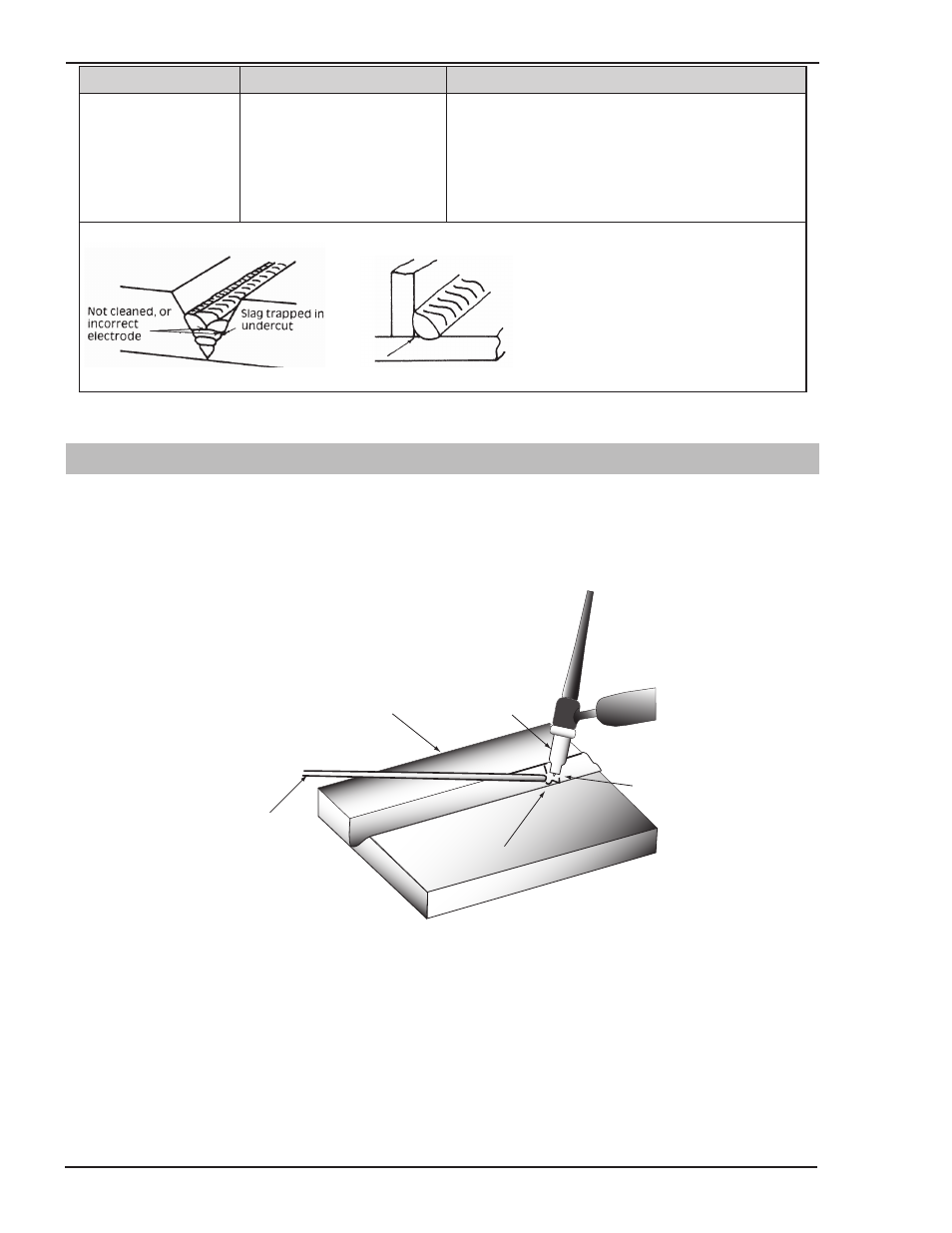

Figure 3: Example of Slag Inclusion

Table 4-1: Welding Problems SMAW (Stick)

4.03 TIG (GTAW) Basic Welding Technique

Gas Tungsten Arc Welding (GTAW) or TIG (Tungsten Inert Gas) as it is commonly referred to, is a welding process

in which fusion is produced by an electric arc that is established between a single tungsten (non-consumable)

electrode and the work piece. Shielding is obtained from a welding grade shielding gas or welding grade shielding

gas which is generally Argon. A filler metal may also be added manually in some circumstances depending on

the welding application.

Welds Made With or Without

Addition of Filler Metal

Work Piece

Can Be Any Commercial

Metal

Gas Cup

Either Ceramic,

High-lmpact or

Water Cooled

Metal

Inert Gas

Shields Electrode

and Weld Puddle

Tungsten Electrode

Non-Consumable

Art # A-09658_AC

Figure 4-28: TIG Welding Application Shot

BASIC WELDING GUIDE

4-12

Manual 0-5345