Arcmaster 401s power source – Tweco ArcMaster 401S User Manual

Page 31

ARCMASTER 401S POWER SOURCE

Manual 0-5345

3-11

INSTALLATION, OPERATION AND SETUP

ARC FORCE CONTROL

This parameter encoder controls in STICK mode only and is used to adjust percentage increase in welding

current and is proportional to arc length (arc voltage). This control provides an adjustable amount of arc control

(or dig). This feature can be particularly beneficial in providing the operator with the ability to compensate for

variability in joint fit up in certain situations with particular electrodes, e.g. cellulose and hydrogen controlled

electrodes. In all welding processes, the amount of penetration obtained is dependent on the welding current;

i.e. the greater the penetration, the greater the current.

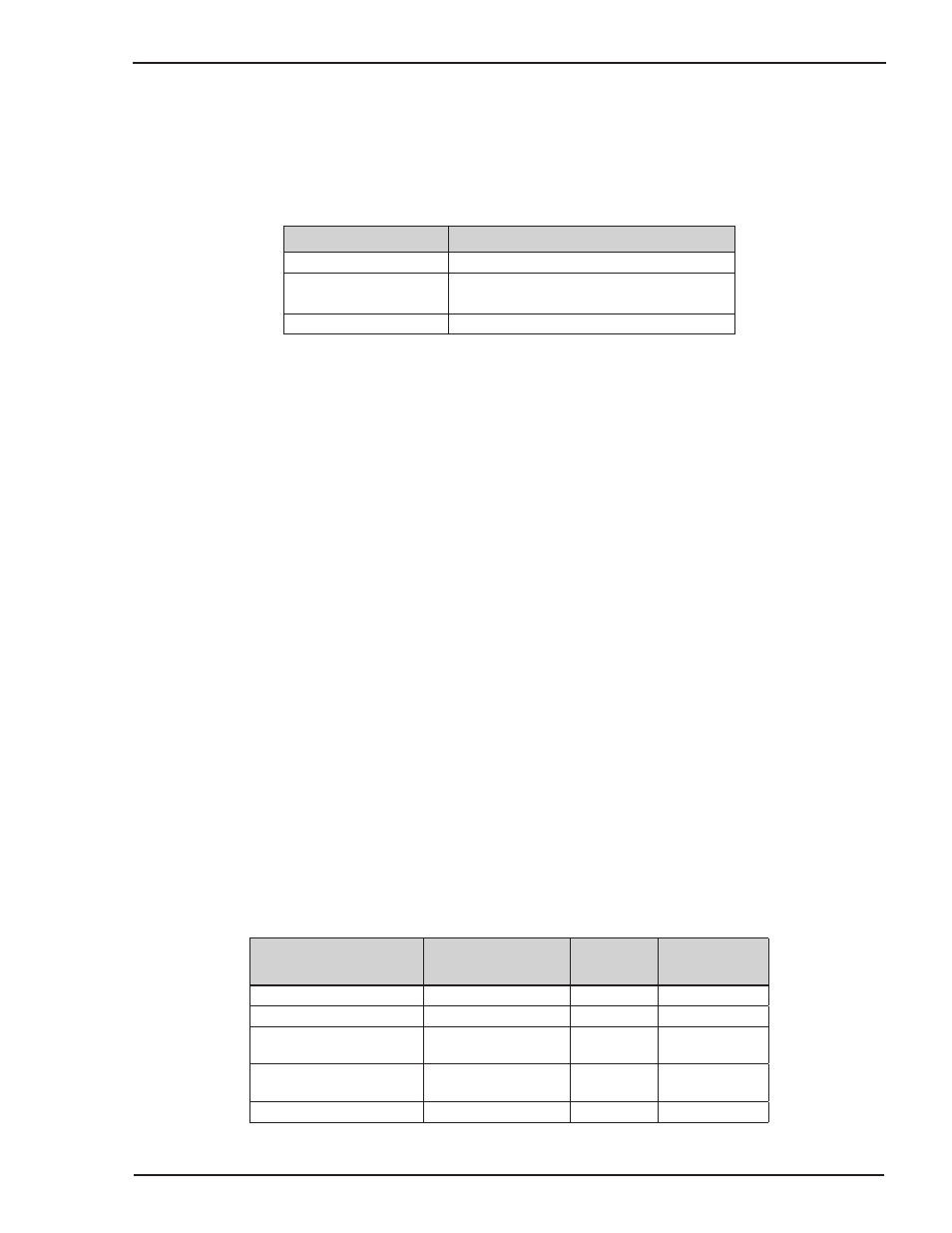

Arc Force Position

Effect on Welding Performance

Minimum (0)

Soft arc, Low spatter, Low penetration

Medium (100%)

Normal arc, Improved fusion

characteristics, Normal penetration

Maximum (200%)

Hard arc, Deep penetration

Table 3-5 Weld Parameter Descriptions

In general, having the Arc Force set at 200% (maximum) allows greater penetration to be achieved. With the

ARC set at 0% (minimum) the Power Source has a constant current characteristic. In other words, varying the

arc length does not significantly affect the welding current. When the Arc Force is set to 100%, it is possible

to control the welding current by varying the arc length. This is very useful for controlling penetration and

side wall wash on vertical up fillet welds.

i) Root runs

During root runs the weld pool forms a “keyhole” shape. If too much weld current is used, the hole blows

out and the weld collapses. If too little weld current is used, the hole closes up and penetration is lost. The

size of the hole also determines the arc length; i.e. as the hole gets bigger, the arc gets longer.

If arc force is used, the increase in the arc length causes the weld current to decrease until the hole starts

to close up but if the hole closes up to much then the arc length decreases which causes the weld current

to increase. Too little or too much arc force makes this process unstable. The operator must adjust the

arc force until a happy medium is reached.

ii) Vertical up welding

When welding vertical up with arc force on, the operator can control the amount of current by changing arc

length, i.e. voltage. Weld metal is deposited by “digging” the electrode into the side of the base metal joint

and then increasing the arc length with a flicking motion, to allow the weld pool to freeze, before digging

the electrode into the other side of the base metal joint.

Without arc force, increasing the arc length does not decrease the weld current sufficiently and the operator

has to manually decrease the current via a Remote Control to freeze the weld pool. This welding current

reduction also reduces the penetration.

The arc force allows the weld pool to freeze during the “flick” phase without decreasing the amount of weld

current available during the “dig” phase thus maximizing penetration.

Weld

Parameter

Parameter Range

Factory

Setting

Incremental

Unit

HOT START (TIG)

50 to 200%

50%

1%

HOT START (STICK)

100 to 200%

125%

1%

WELD (A) (1 phase)

TIG or STICK

10 to 300A

100A

1A

WELD (A) (3 phase)

TIG or STICK

10 to 400A

100A

1A

ARC FORCE

0 to 200%

100%

1%

Table 3-6 Weld Parameter Setting