Arcmaster 401s power source – Tweco ArcMaster 401S User Manual

Page 28

ARCMASTER 401S POWER SOURCE

INSTALLATION, OPERATION AND SETUP

3-8

Manual 0-5345

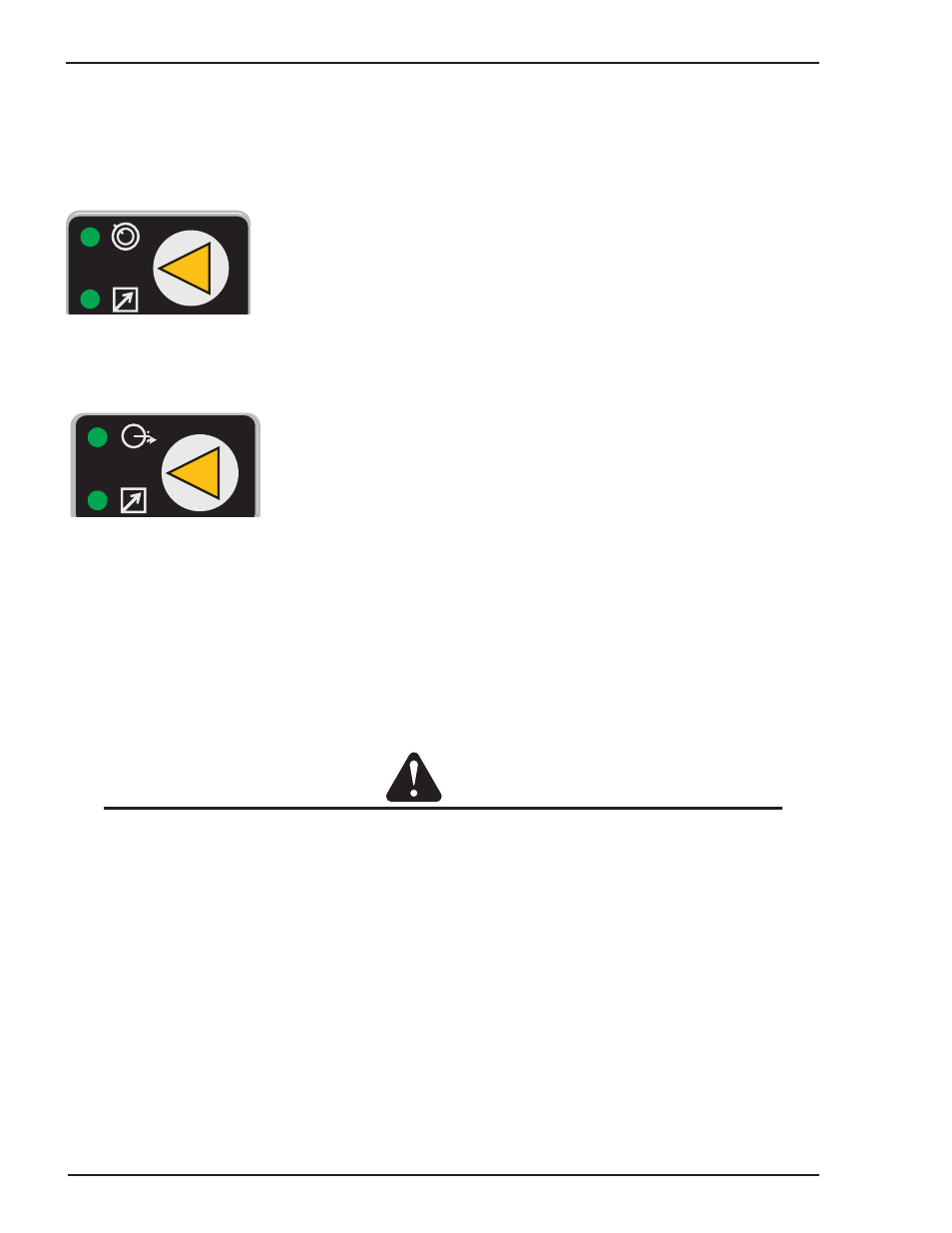

Lift TIG (GTAW)- The Process light is illuminated.

The Stick function has two modes: Stick (SMAW)- The Process light is illuminated; Arc Gouging (CAC-A)- The

Process light is blinking.

6010 vertical up (SMAW)- The Process light is illuminated; 6010 Vertical down (SMAW)- the light is blinking.

6 Remote Control

The remote control A/V is for both Current or Voltage depending on the process selected. This control toggles

between Local and Remote. Refer to 3.12 Special Function for more info.

7 Contactor Control

Contactor Control either enables the weld output or assigns this function to a remote device. Refer to 3.12

Special Function for more info.

8 Positive Welding Terminal

Welding current flows from the Power Source via heavy duty Dinse type terminal. It is essential, however, that

the male plug is inserted and turned securely to achieve a sound electrical connection.

9 Negative Welding Terminal

Welding current flows from the Power Source via heavy duty Dinse type terminal. It is essential, however, that

the male plug is inserted and turned securely to achieve a sound electrical connection.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused in

the terminal.

10 Intelligent Fan Control

The intelligent cooling system is designed to reduce dust and foreign material build-up, while providing optimum

cooling. Machine does a fan test at startup. Fan speed is controlled by various parameters and follows no

fixed sequence. Parameters are: - temperatures measured by temperature sensors - output current - output

active - welding time. If machine is switched on in a cold state, fans will be off (except fan test). If machine

is switched off, while it’s hot and running with high fan speed, and then switched back on, fans will turn on

with high speed again. After machine has cooled down, fans will stop.