Arcmaster 401s power source, 11 setup for stick (smaw) welding – Tweco ArcMaster 401S User Manual

Page 33

ARCMASTER 401S POWER SOURCE

Manual 0-5345

3-13

INSTALLATION, OPERATION AND SETUP

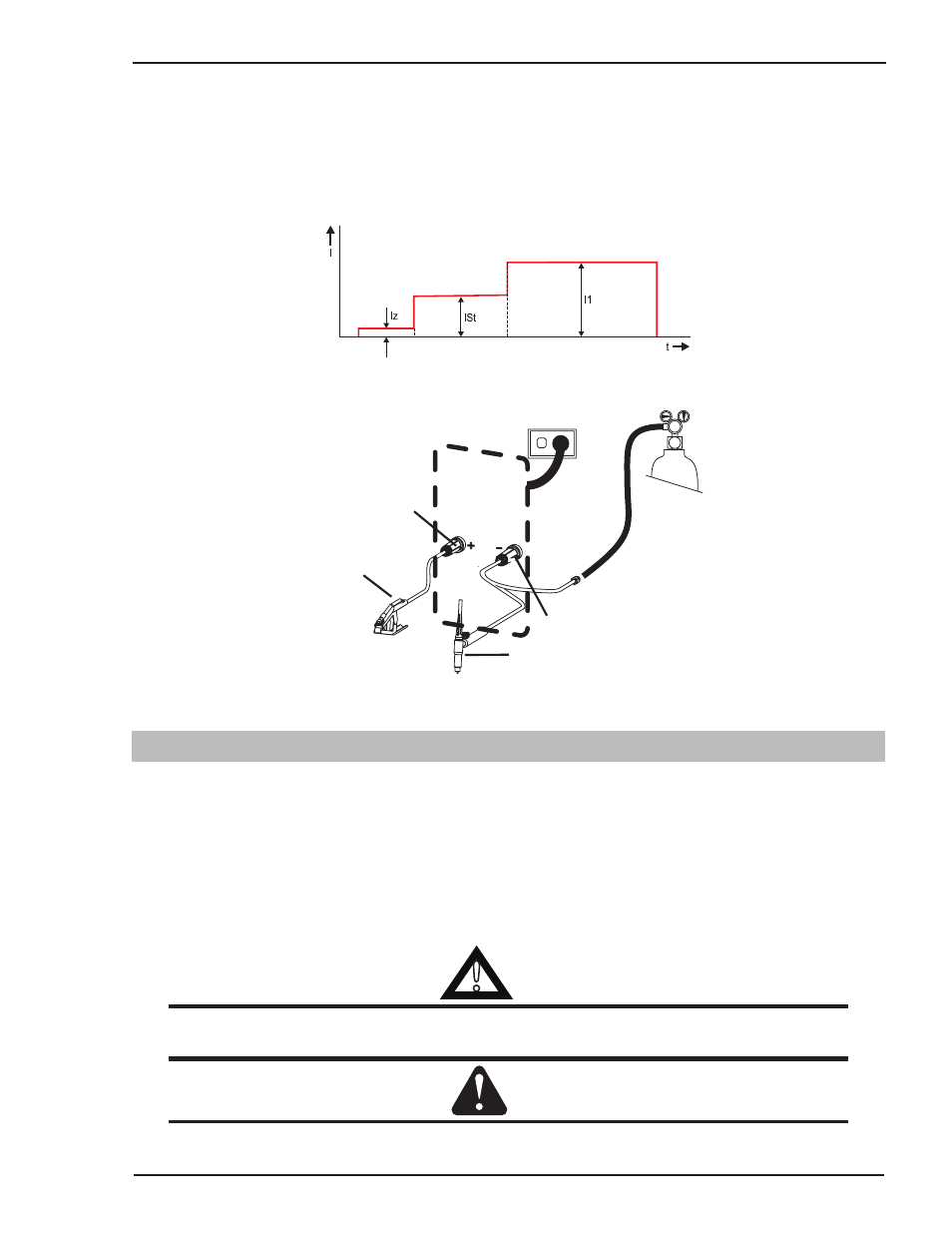

Graphic for TIG

I

Current

I1

Welding current

ISt

Hot start current

Iz

Short circuit

t

Time

tSt

Hot start

Art # A-12456

Figure 3-5 TIG Current Routing Diagram

ARCMASTER 401S

Negative Welding

Terminal (-)

Work Lead

Positive Welding

Terminal (+)

Tig Torch

Art # A-12554

Figure 3-6 Setup for TIG (GTAW) Welding

3.11 Setup for STICK (SMAW) Welding

A. Remove all packaging materials. Do not block the air vents at the front or rear of the Power Source.

B. Connect the Electrode Holder to the positive welding terminal (+) (or negative welding terminal (-)). If in doubt,

consult the electrode manufacturer. Welding current flows from the Power Source via dinse type connectors. It

is essential, however, that the male plug is inserted and turned securely to achieve a sound electrical connection.

C. Connect the work lead to the negative welding terminal (-) (or positive welding terminal (+)). If in doubt, consult

the electrode manufacturer. Welding current flows from the Power Source via dinse type connectors. It is

essential, however, that the male plug is inserted and turned securely to achieve a sound electrical connection.

!

WARNING

The polarity of the electrode depends on the type of electrode and the welding process. Please follow

the manufacturer's instructions on the electrode packaging for this purpose.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused in

the terminal.