Arcmaster 401s power source, 09 welding parameters – Tweco ArcMaster 401S User Manual

Page 30

ARCMASTER 401S POWER SOURCE

INSTALLATION, OPERATION AND SETUP

3-10

Manual 0-5345

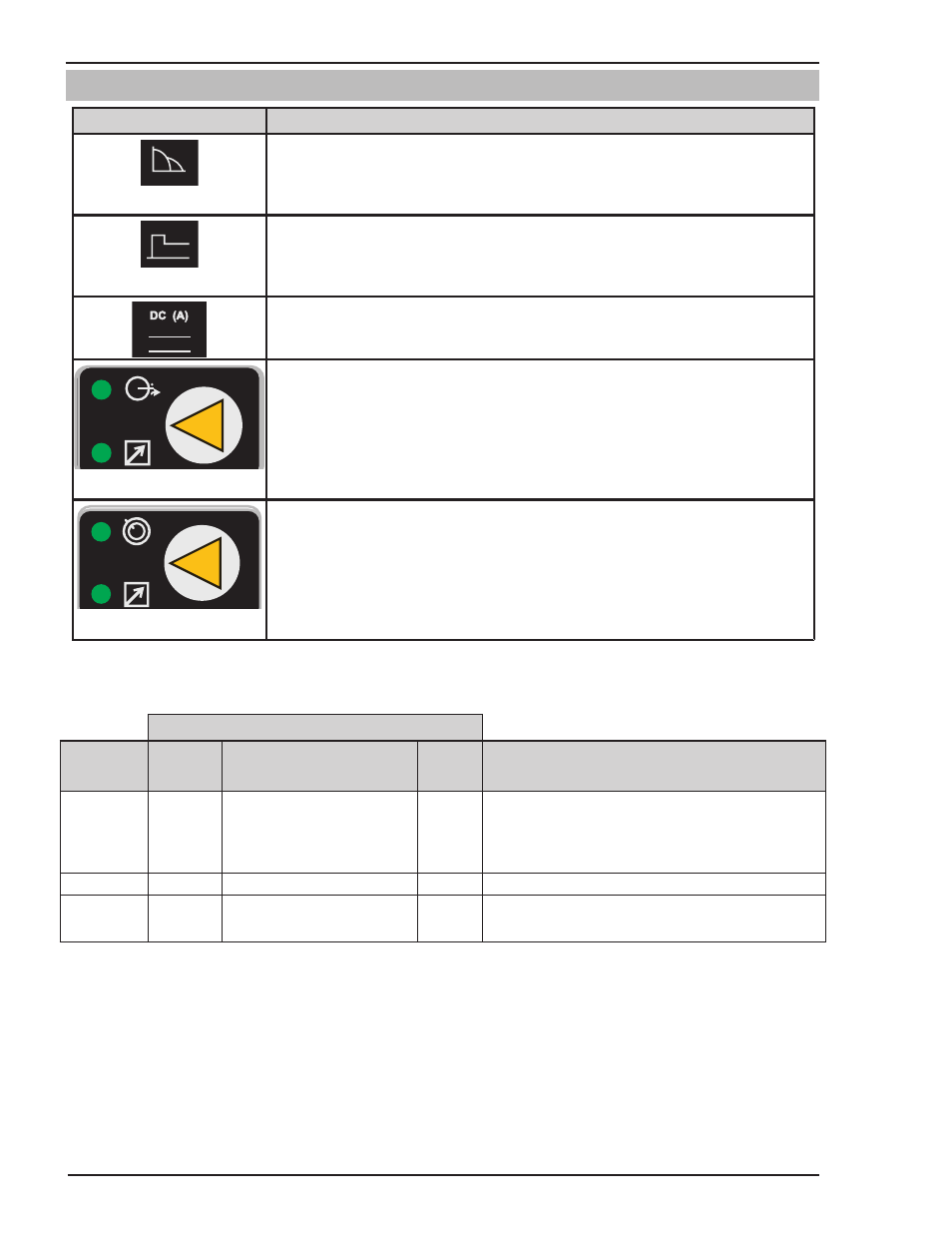

3.09 Welding Parameters

Parameter

Description

Arc Force

This parameter provides an adjustable short circuit current in STICK welding to

improve electrode sticking and arc stability

Hot Start

This parameter operates in STICK weld mode and is used to improve the

start characteristics for stick electrodes. e.g. low hydrogen electrodes. This

parameter also works in TIG mode allowing a softer or harder arc start. It sets

the peak start current on top of the (WELD) current.

Weld Current (Amperage) - when lit Encoder Control sets the STICK and TIG

WELD current.

Contactor Control

Contactor operation in TIG and Stick modes.

When the local Control LED is illuminated the output is enabled, and when the

Remote Control is illuminated the output is enabled by a remote control.

Remote Control

Selects either local or remote amperage or voltage control depending on the

selected process. Local Control allows the voltage or current to be adjusted

on the front panel, while Remote Control is used if you have a remote control

connected to the welder.

Table 3-3 Welding Parameters Description

Weld Process Selection

Weld Mode

Weld

Parameter

STICK/

GOUGING

6010 VERTICAL UP/

6010 VERTICAL DOWN

LIFT

TIG

Description

HOT START

√

√

√

Start current in amps is added or subtracted.

In STICK mode the Hot Start is 100% to 200%,

factory default 125%; while in TIG mode the

range is 50% to 200%, factory default 50%.

WELD (A)

√

√

√

WELD (A) current for STICK or LIFT TIG.

ARC FORCE

√

√

×

Adjusts percentage increase in welding current

and is proportional to arc length (arc voltage).

Table 3-4 Weld Process Selection verses Weld Mode

Weld Parameter Descriptions

HOT START

This parameter encoder controls in Stick and TIG modes. Hot start can subtract 50% of the weld current during

arc starts some times desirable in TIG welding, or add up to 200% of weld current during arc starts, helping

with low hydrogen electrode ignition.

WELD (A)

This parameter encoder controls the Stick, Gouging, and TIG weld current.