Transmig 250i installation/setup – Tweco 250i Multi Process Welding Inverter 2RT Wire Feeder User Manual

Page 54

TRANSMIG 250i

INSTALLATION/SETUP

INSTALLATION/SETUP 3-36

Manual 0-5187

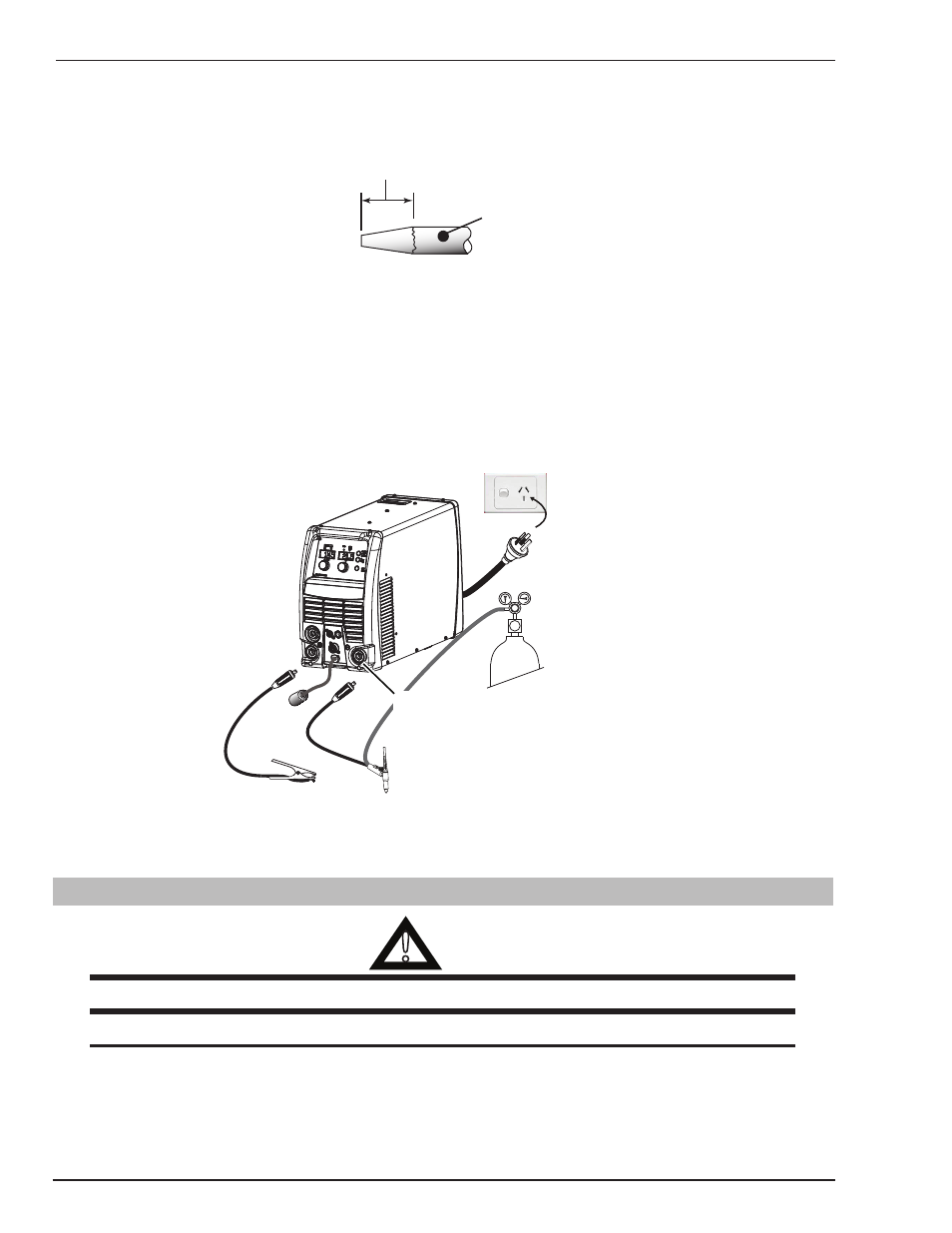

6. The tungsten must be ground to a blunt point (similar to a pencil) in order to achieve optimum welding results.

See illustration. It is critical to grind the tungsten electrode in the direction the grinding wheel is turning. Grind

at a 30 degree angle and never to a sharp point.

A-00503_AB

Electrode

2 to 2-1/2 Times

Electrode Diameter

Figure 3-31: Electrode sharpening

7. Install the tungsten with approximately 3.2mm to 6.4mm sticking out from the gas cup, ensuring you have

correct sized collet.

8. Tighten the back cap.

9. Turn the switch to the “ON” position. The power L.E.D. light should illuminate.

10. Set the welding process to LIFT TIG.

11. Set the Weld Current Control Knob to the desired amperage.

+

-

Art # A-10284

Negative Output

Terminal

(Dinse® type 50mm)

Ensure that the gas

cylinder is secured to

a building pillar, wall

bracket or otherwise

securely fixed in an

upright position.

Figure 3-32: Setup for LIFT TIG (GTAW) Welding

12. You are now ready to begin LIFT TIG Welding.

3.26 Set-up for Metal Manual Metal Arc Welding (MMAW)

!

WARNING

Before any welding is to begin, be sure to wear all appropriate and recommended safety equipment.

NOTE

The following set up is known as DC Electrode Positive or reverse polarity. Please consult with the stick

electrode manufacturer for specific polarity recommendations.

1. Switch the ON/OFF Switch (located on the rear panel) to OFF.

2. Attach the stick and work leads as shown in Figure 3-33.