Transmig 250i installation/setup – Tweco 250i Multi Process Welding Inverter 2RT Wire Feeder User Manual

Page 38

TRANSMIG 250i

INSTALLATION/SETUP

INSTALLATION/SETUP 3-20

Manual 0-5187

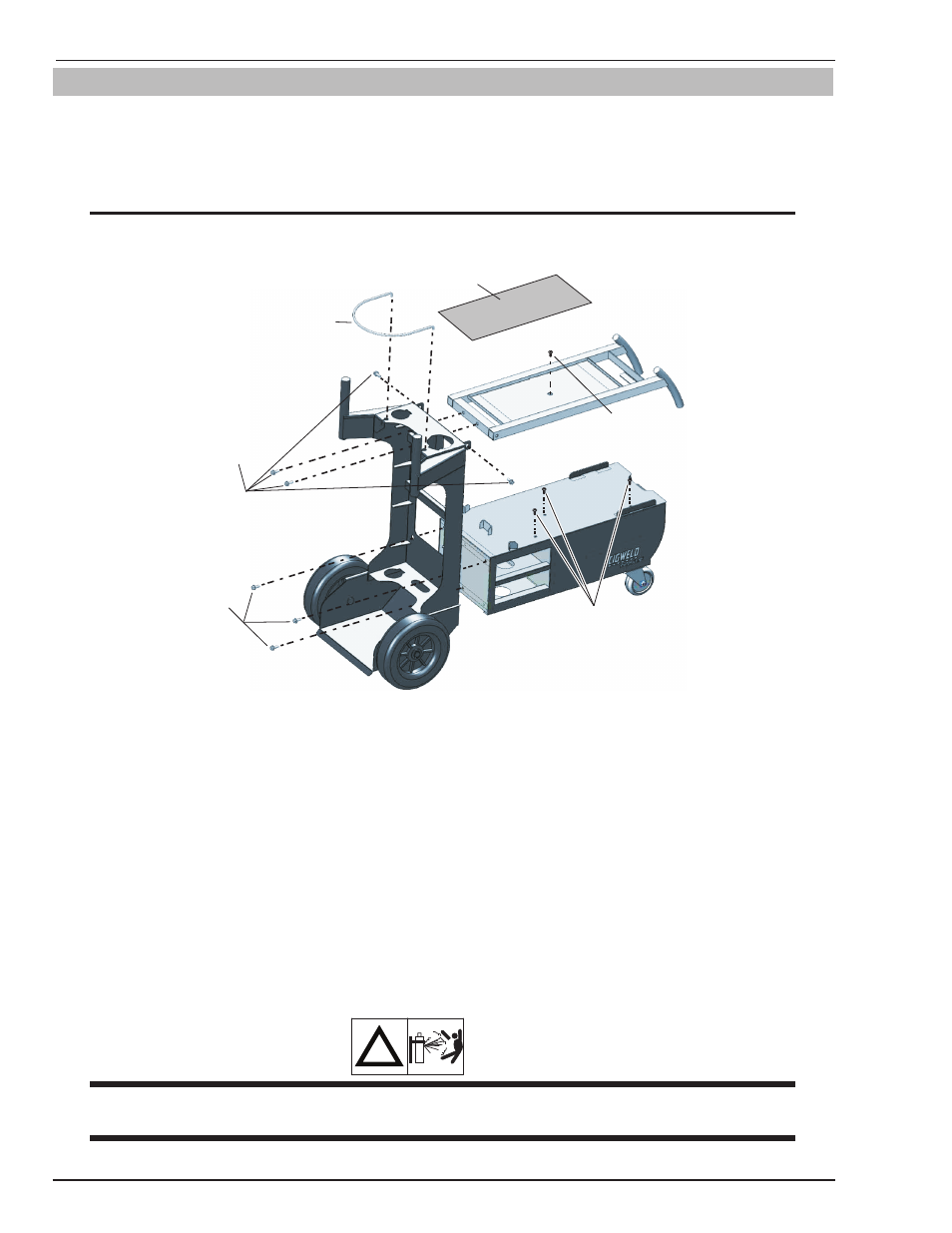

3.12 Assembly and Fitting of Optional Welding Trolley

Assemble the Welding Trolley according to Figure 3-14. Read all steps before beginning and ensure all hardware is

tightened properly.

1. Attach the front base section to the upright rear section with the 3 screws provided.

NOTE

If attached, the optional roll cage must be removed before mounting to the Welding Trolley as the same

mounting holes are used for both.

Art # A-10326

4 screws

provided

3 screws

provided

Chain

Rubber Mat

Screw from top

of 250i

3 screws provided

to secure 250i

Figure 3-14: Welding Trolley Assembly

2. Mount the 250i power source to the bottom tray aligning the 3 holes in the bottom of the power source with

the 3 holes in the base. Secure with the 3 screws provided.

3. Temporarily remove the top center screw in the 250i case. Attach the top tray using four screws provided ensur-

ing the tab on the front of the tray captures the hand hold on the front of the 250i power source. Re-install the

screw through the hole in the centre of the top tray into the top of the 250i case. Ensure that all fixing screws

are in place and tightened.

4. Place rubber mat on the top tray and then place the 2RT Wire Feeder on that.

5. Position a gas cylinder on the rear tray of the Trolley and lock securely to the Trolley cylinder bracket with the

chain provided. If this arrangement is not used then ensure that the gas cylinder is secured to a building pillar,

wall bracket or otherwise securely fixed in an upright position.

6. Attach Gas Regulator and hose per instructions found in sub Section 3-22.

!

WARNING

Secure the welding grade shielding gas cylinder in an upright position by chaining it to a suitable stationary

support to prevent falling or tipping.