11 fitting of optional roll cage, Fitting of optional roll cage -18, Transmig 250i installation/setup – Tweco 250i Multi Process Welding Inverter 2RT Wire Feeder User Manual

Page 36

TRANSMIG 250i

INSTALLATION/SETUP

INSTALLATION/SETUP 3-18

Manual 0-5187

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused in the

terminal.

Remove any packaging material prior to use. Do NOT block the air vents at the front or rear of the Welding

Power Source.

NOTE

Depending on the type of wire you will be using the Welding Power Cable may need to be switched. Follow

the wire manufacturers recommendation.

NOTE

Spool hub and feed plate set up and operation are the same as the 250i which can be reviewed later in this

section starting at 3.14.

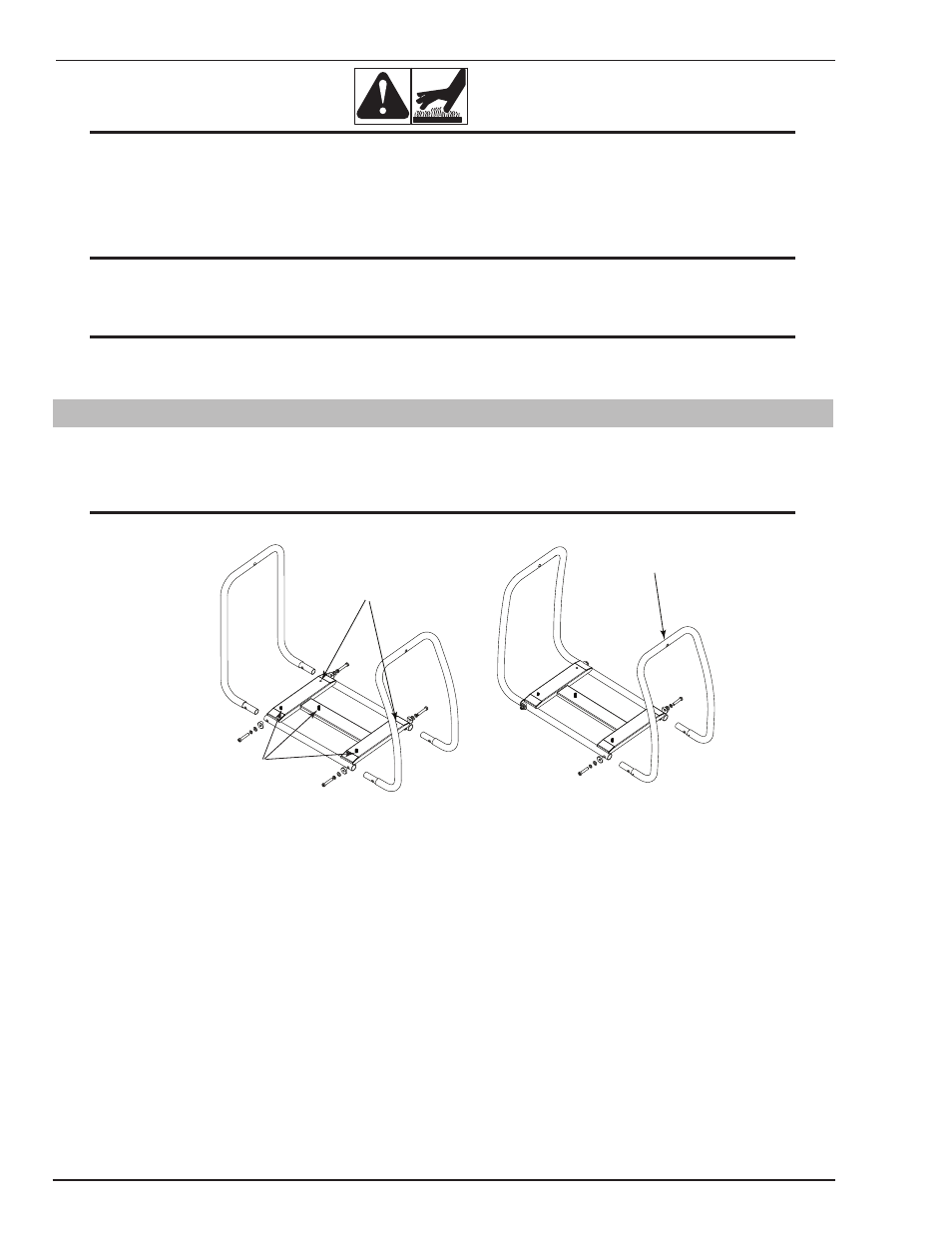

3.11 Fitting of Optional Roll Cage

1. Assemble the Roll Cage according to Figure 3-11. Ensure that all hardware is properly tightened and will not

come apart with the power source attached.

NOTE

You will need to wait to attach the front roll bar until after the welder has been mounted.

Art # A-10336

These holes are not used

Note the orientation

of the 3 studs

Rear

Front

Do not attach front yet

Rear

Front

Figure 3-11: Roll Cage Assembly

2. Disconnect power from the power source.

3. Remove the top centre screw in the cover and open the side cover to the wire spool so you can see the 3 holes

that will need to align with the mounting studs from the roll cage.

4. Carefully lift the unit and maneuver into place aligning the 3 studs with the 3 holes in the bottom of the power

source.