Transmig 200i – Tweco 200i Multi Process Welding Inverter User Manual

Page 25

TRANSMIG 200i

Manual 0-5209

3-7

INSTALLATION, OPERATION AND SETUP

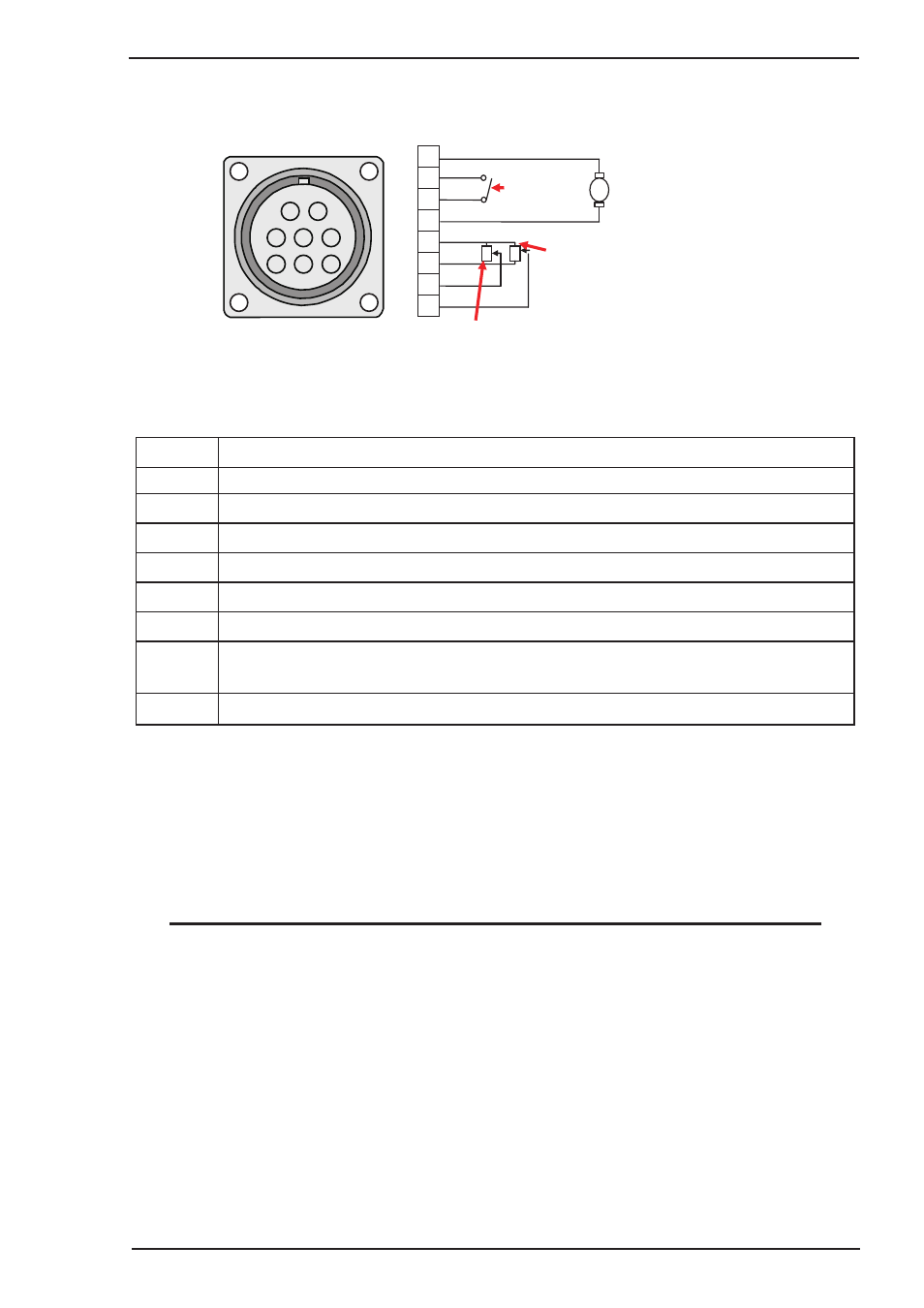

9. Remote Control Socket

The 8 pin Remote Control Socket is used to connect remote control devices to the welding power source.

To make connections, align keyway, insert plug, and rotate threaded collar fully clockwise.

Trigger Switch

Remote Wirespeed in GMAW mode

Remote Amps in GTAW mode

Remote Volts in

GMAW Mode

1

2

3

4

5

6

7

8

W V

3

4

5

6

7

8

1

2

Negative

Spool Gun Motor

Positive

Art # A-10421

Figure 3-3: Remote Control Socket

Socket Pin

Function

1

Spool Gun Motor Negative

2

Trigger Switch Input

3

Trigger Switch Input

4

Spool Gun Motor Positive

5

5k ohm (maximum) connection to 5k ohm remote control potentiometer.

6

Zero ohm (minimum) connection to 5k ohm remote control potentiometer.

7

Wiper arm connection to 5k ohm remote control Wirespeed GMAW (MIG) mode potentiometer.

Wiper arm connection to 5k ohm remote control Amps GTAW (TIG) mode potentiometer.

8

Wiper arm connection to 5k ohm remote control Volts GMAW (MIG) mode potentiometer.

Table 3-1

Note that the remote local switch (item 18) located in the wirefeed compartment should be set to remote

for the amperage/voltage controls to be operative.

10. Multifunction Control - Voltage, Down Slope & Arc Force

The multifunction control knob is used to adjust Voltage (MIG Mode), Down slope (TIG Mode) and Arc

Force (STICK Mode) depending on the welding mode selected.

NOTE

The preview functionality provided on this power source is intended to act as a guide only. Some

differences may be observed between preview values and actual welding values due to factors

including the mode of welding, differences in consumables/gas mixtures, individual welding

techniques and the transfer mode of the welding arc (ie dip versus spray transfer). Where exact

settings are required (in the case of procedural work), it is recommended that alternate measurement

methods be utilised to ensure output values are accurate.

When GMAW/FCAW (MIG) Mode is Selected

In this mode the control knob is used to adjust the output voltage of the unit. The welding voltage is

increased by turning the knob clockwise or decreased by turning the knob anti-clockwise. The optimum

voltage level required will dependent on the type of welding application. The setup chart on the inside

of the wire feed compartment door provides a brief summary of the required output settings for a basic

range of MIG welding applications.