06 prewelding procedure, 07 welding - 2 step operation, Ultrafeed va 4000 – Tweco VA 4000 Ultra-Feed User Manual

Page 34

ULTRAFEED VA 4000

4-6

September 18, 2012

WARNING

In semiautomatic or automatic wire welding,

the welding wire, wire reel (if used), input

guide, feed rolls, output guide, feedhead, and

welding gun metal parts are all ELECTRICALLY

“HOT”.

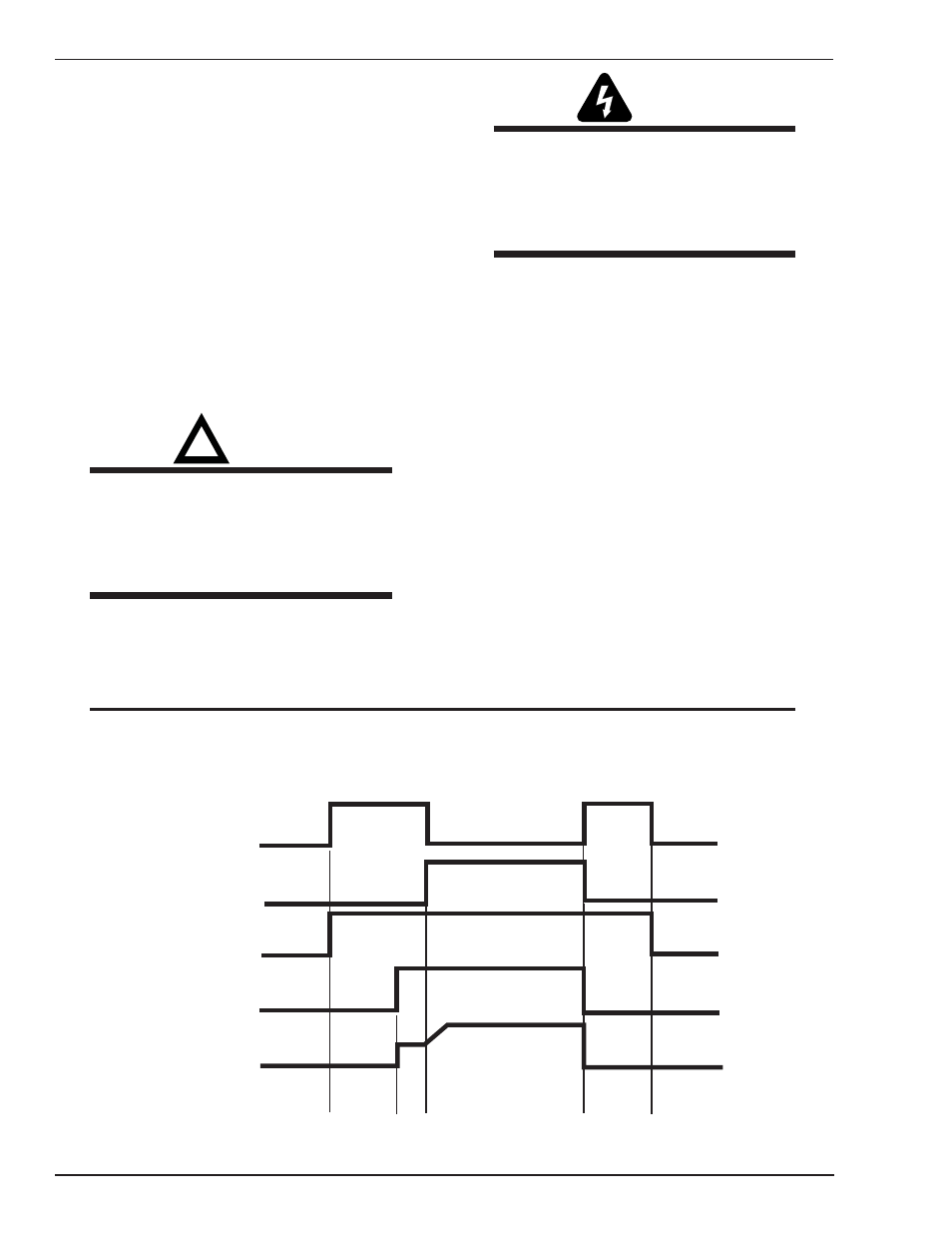

4.07 Welding - 2 Step Operation

Refer to Figure 4-5.

Position the welding gun above the workpiece and de-

press the gun switch trigger. Depressing the gun switch

trigger enables the gas valve, wire feed motor, and power

source; the welding process begins. To end the weld, re-

lease the gun switch trigger which disables the gas valve,

wire feed motor, and power source.

4.06 Prewelding Procedure

Follow all installation instructions for the wire feeder,

the welding power source, and the welding gun before

attempting to operate the Ultrafeed VA 4000.

1. Make sure all necessary connections have been

made (Refer to “Connections” in the Installation

chapter of this manual).

2. Turn ON the power source and the wire feeder.

3. Push the PURGE switch of the feeder and adjust

the flow of shielding gas.

4. Push the INCH switch of the feeder and adjust

the wire feed speed to the desired value by means

of the wire feed speed control.

!

WARNING

If the gun switch is depressed, the electrode

(welding wire) is electrically “hot”. Do not

permit it to touch any metal or a welding arc

may be established which may be injurious to

someone’s eyes (flash) or skin (burn).

5. Adjust the voltage of the power source to the

desired value. The gun switch must be triggered

to close power source contactor.

NOTE

When the gun switch is released, gas will continue to flow for approximately 0.5 seconds. This is a

feature of the system and is normal.

Gun Trigger

Arc Established

Gas

Contactor

WireFeed

Runin %

Postflow

Preflow

Ramp Rate

Art # A-06986