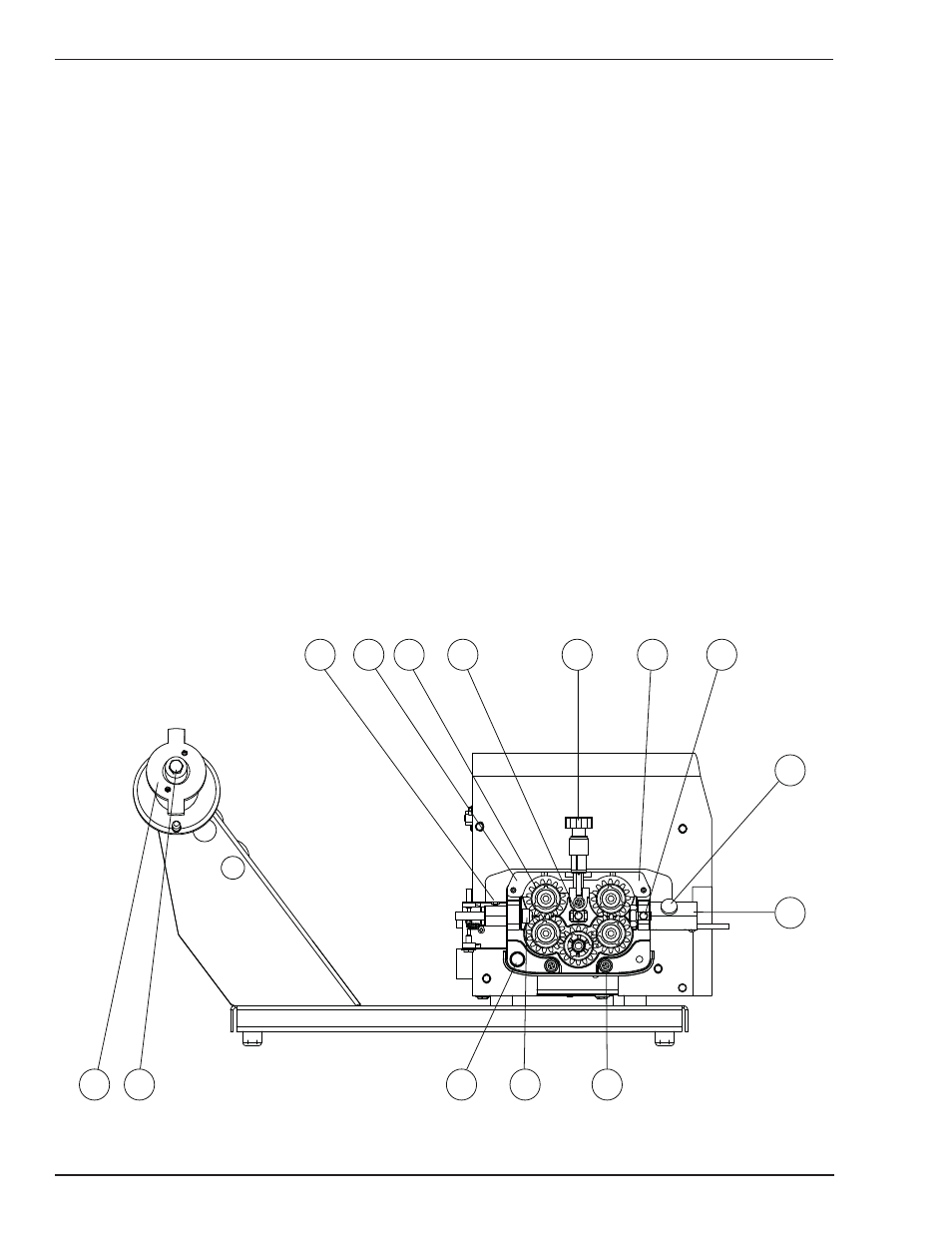

03 feedhead components, 03 feedhead components -4, Ultrafeed va 4000 – Tweco VA 4000 Ultra-Feed User Manual

Page 32

ULTRAFEED VA 4000

4-4

September 18, 2012

18

19

20

21

22

23

24

25

26

27

28

30

29

21

Art # A-06984

Figure 4-4: Feedhead Components

4.03 Feedhead Components

18.

INPUT GUIDE LOCKSCREW: Tighten this

lockscrew to secure the input wire guide.

19.

SPRING TENSION KNOB: Use the spring

tension knob to adjust the amount of force the feed

rolls exert on the welding wire.

20.

FEEDROLL GEAR / KNOB : This knob is used

to secure the feedroll to the pressure arm. Rotate

the knob to change the feedroll.

21.

PRESSURE ARM: This arm pivots off the front

of the feedhead to allow access to the wire guides

and wire path.

22.

CENTER GUIDE LOCKSCREW: Tighten this

lockscrew to secure the center wire guide.

23.

OUTPUT GUIDE LOCKSCREW: Tighten this

lockscrew to secure the output wire guide.

24.

GUN CLAMP KNOB: This knob is used to

tighten the welding gun into the feedhead.

25.

GUN ADAPTER: This adapter accepts the

welding gun plug. It can optionally be replaced

with different adapters for a variety of different

guns.

26.

FEEDHEAD POSITIONING SCREW (3x): These

screws are tightened to position the rotation angle

of the feedhead. To change the angle of the

feedhead, LOOSEN these 3 screws and turn the

feedhead to the desired angle. Then tighten the 3

screws to secure.

27.

INPUT WIRE GUIDE: This guide is required to

direct the welding wire from the drive roll to the

welding gun cable.

28.

WELD CABLE CONNECTION: This is where the

power source welding cable is connected to the

feeder. Make sure this connection is tight or arcing

could occur.

29.

HUB TENSION BOLT: The hub tension bolt is

used to adjust the wire spool tension which acts

as a mechanical brake to assist in the stopping of

the welding wire when the gun switch is released.

30.

WIRE SPOOL HUB NUT (not shown): The wire

spool hub nut is used to secure the spool of welding

wire.