Tweco Ultima 150 User Manual

Page 33

Manual 0-2472

27

SECTION 5: GENERAL MAINTENANCE

2. No pilot arc /weak pilot arc

a. Pilot current too low

• Increase current by adjusting the Pilot Arc CUR-

RENT Adjust potentiometer on front panel of

the power supply.

b. Plasma Gas flow too low

• Increase flow rate

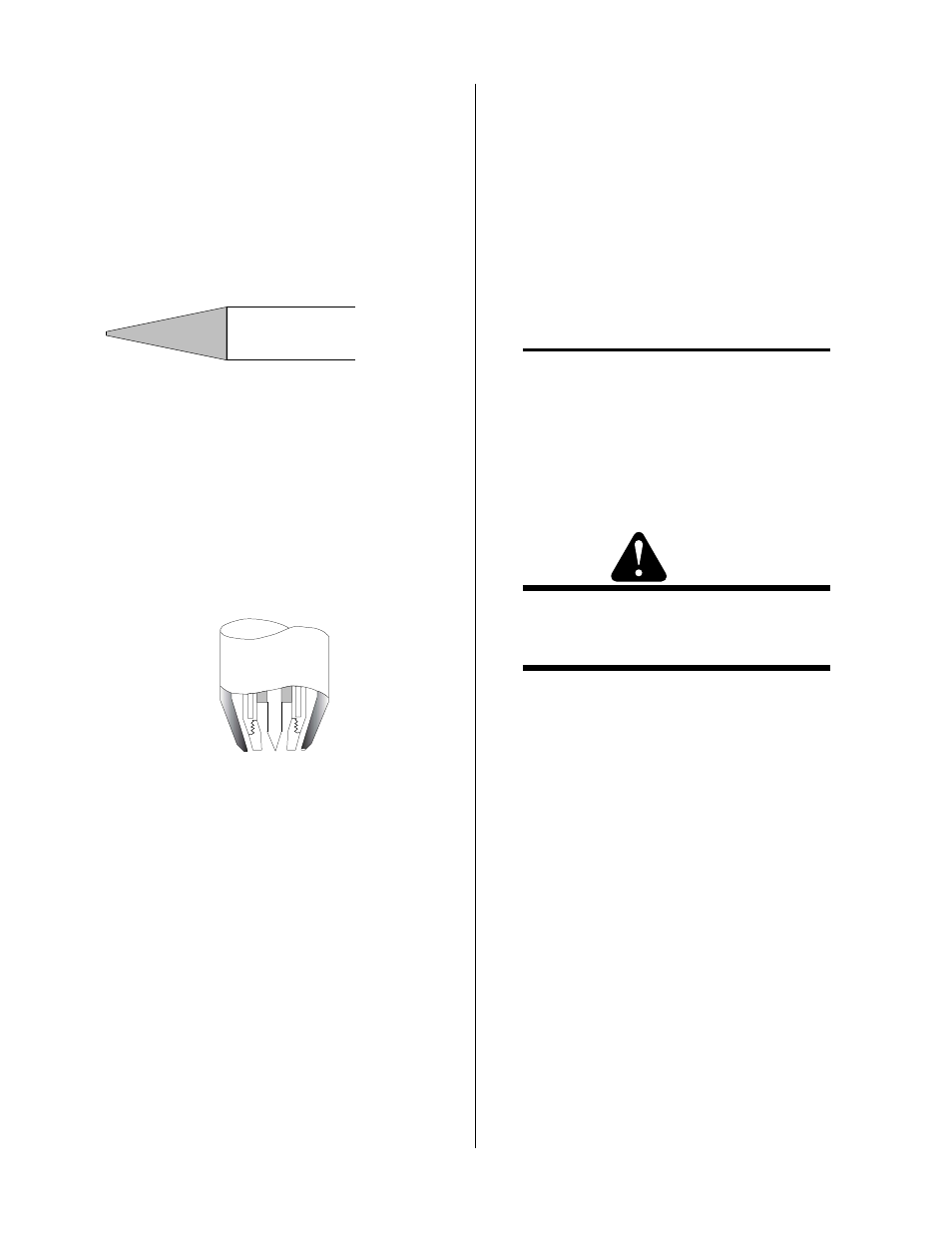

A-00827

• Remove sharp point (.015-.025) flat

• Sharpen to 20 degree included angle

• Surface finish minimum 32 microinch

Figure 5-4 Preparation Specifications

c. Electrode setting at maximum electrode setback

• Adjust electrode setting

;

;

;

;

;

;

;

;;

;;

;;

;;

A-00828

Figure 5-5 Minimum Electrode Setback

d. Improper electrode preparation

• Adjust electrode setting according to specifica-

tions

4. Coolant light is RED

a. Coolant Conductivity level is high

• Replace Coolant in per Section 3.11, Filling Cool-

ant Reservoir

5. Tungsten electrode in torch is discolored (bluing)

a. Gas leak is present

• Check system for gas leaks. One way to verify

gas leaks is to turn off the system and gas sup-

ply at source and watch pressure gauges on

regulators. With no gas flow, the pressure at the

regulators should remain constant. If the pres-

sure decreases, there is a leak in the system

• If gases are supplied to system via a pipeline,

the pipeline must be leakproof and excess sta-

tion drops must be closed

CAUTION

The pipeline should always be pressurized. Other-

wise the collection of moisture can result, causing

sever torch parts damage.

b. Contamination is present

• Check operational procedures. Improper start-

up/shut down procedures can contaminate the

electrode.

WARNING

Never use a rubber hose to supply gas to system;

moisture can impregnate rubber and damage the

torch parts and torch head.

F. DC Problems

1. No welding current/Pilot Arc On (no DC light)

a. Remote switch for Weld Arc ON not enabled

• Check remote switch to make sure it is on

• Check control signal assignments (J20 pins 3 to

4). Refer to Appendix III, Remote Wiring

• Check connections from J20 to TB1 on Logic

Board (LBD). Refer to Appendix III, Remote

Wiring

b. Work cable not attached or incorrectly attached to work

piece

• Attach work cable to piece per instructions in

Section 3.06, Work Cable Connection

G. Welding Problems

See the appropriate torch manual for torch troubleshoot-

ing.