06 work cable connection, 07 plasma and shield gas connections – Tweco Ultima 150 User Manual

Page 22

SECTION 3: INSTALLATION

16

Manual 0-2472

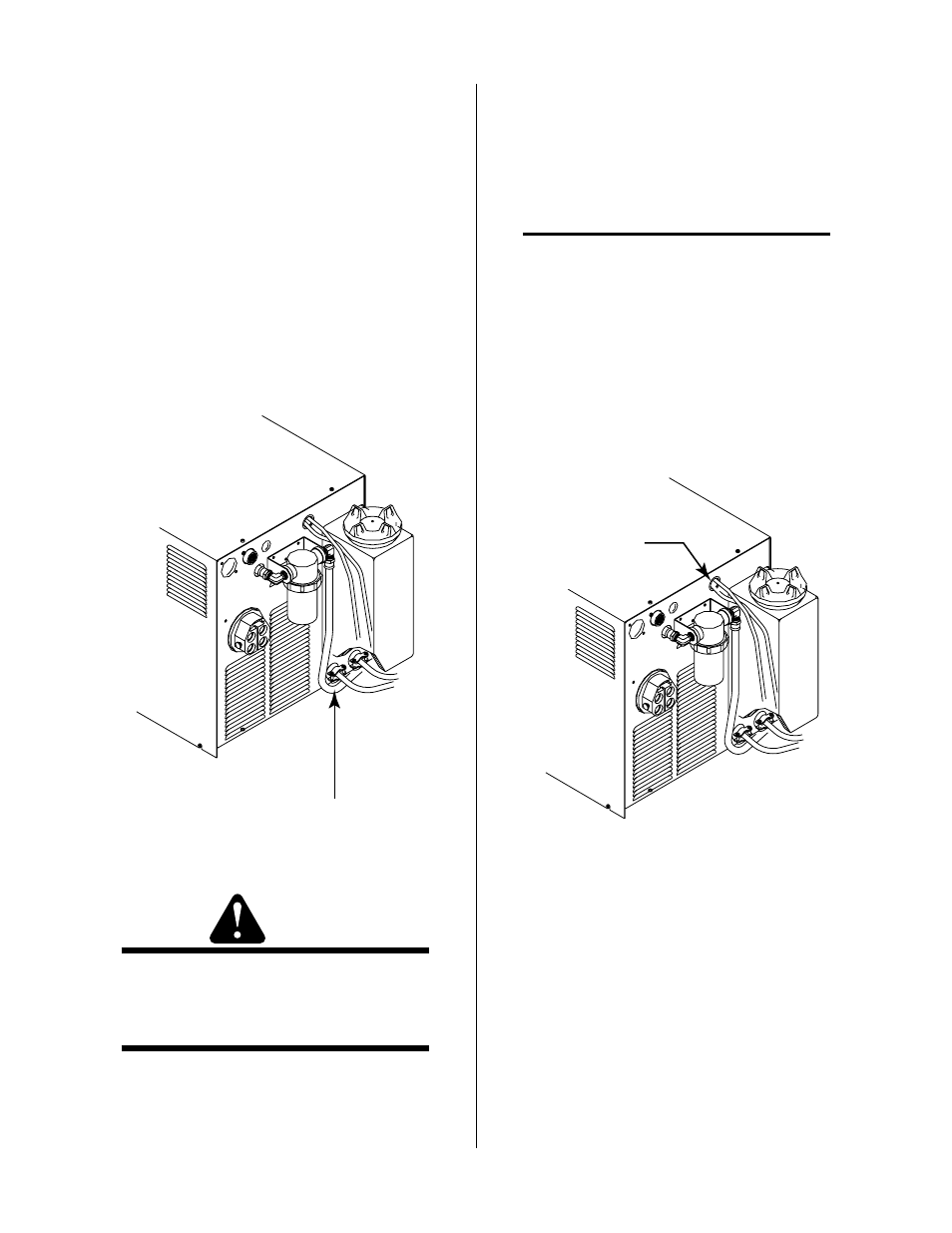

3.06 Work Cable Connection

High frequency pilot arc initiation generates a certain

amount of electromagnetic interference (EMI), commonly

called RF noise. This RF may interfere with other elec-

tronic equipment such as CNC controllers, etc. The sys-

tem is designed with shielded torch leads to help prevent

this problem. To further minimize RF interference, make

sure the work cable is properly connected when installing

mechanized systems.

1. Make sure the work cable is securely fastened to

the WORK connection on the rear panel of unit.

2. Make a solid connection between the work cable

and the work piece or welding machine.

Work Cable Connection

A-00818

Figure 3-6 Rear Panel Work Cable Connection

WARNING

Make sure the ground wire is designated GND on

the other end of the cable. Electric shock and dam-

age to the unit could occur if power is applied to the

GND terminal.

3.07 Plasma and Shield Gas

Connections

The ULTIMA-150 power supply comes with two 10' gas

supply hoses. Plasma and shield gases are connected at

the rear of the ULTIMA-150 power supply unit.

NOTE

It is not recommended to supply both plasma and

shield gas from one (1) regulator via "Y" connec-

tions. It is an additional source for leaks and flow

rates of the gases can be impacted when one is

changed.

1. Connect the Plasma (black or no tape) and Shield

(yellow tape) gas supply hoses from the rear of the

unit to the gas supply regulators.

2. Set pressure regulators on gas cylinders at 35 psi.

Plasma and Shield

Gas Connections

A-00819

Figure 3-7 Gas Connections

3. Plasma gas flows when the main power circuit

breaker is turned on. Gas flow rates are controlled

by the Plasma and Shield gas flow meters located

on the front panel. Gas flow rates typical for most

applications are:

Plasma Gas: 1 - 1.5 scfh

Shield Gas: 15-20 scfh

4. Shield gas can be selected to operate ON or OFF

when the pilot arc is off. For Shield gas ON, jumper

across TB1 pins 17 to 18.