04 torch operation, Confirm led indicators, Select current range – Tweco Ultima 150 User Manual

Page 28: Select remote/panel mode, Adjust current limiter, Preview pilot current, Preview weld current, Pilot on, Torch, Enable arc

SECTION 4: OPERATION

22

Manual 0-2472

4. Confirm LED indicators

PILOT ARC

PREVIEW

ON

CURRENT

SET

A

A

CURRENT

0.5-15

5-150

PREVIEW

ARC

VOLTS

A / V

A

LIMIT

A

PANEL

REMOTE

A

COOL

PILOT

DC

GAS

TEMP

AC

A

V

RANGE

5

6

7

8

9

10

11

12

13 14

A-00822

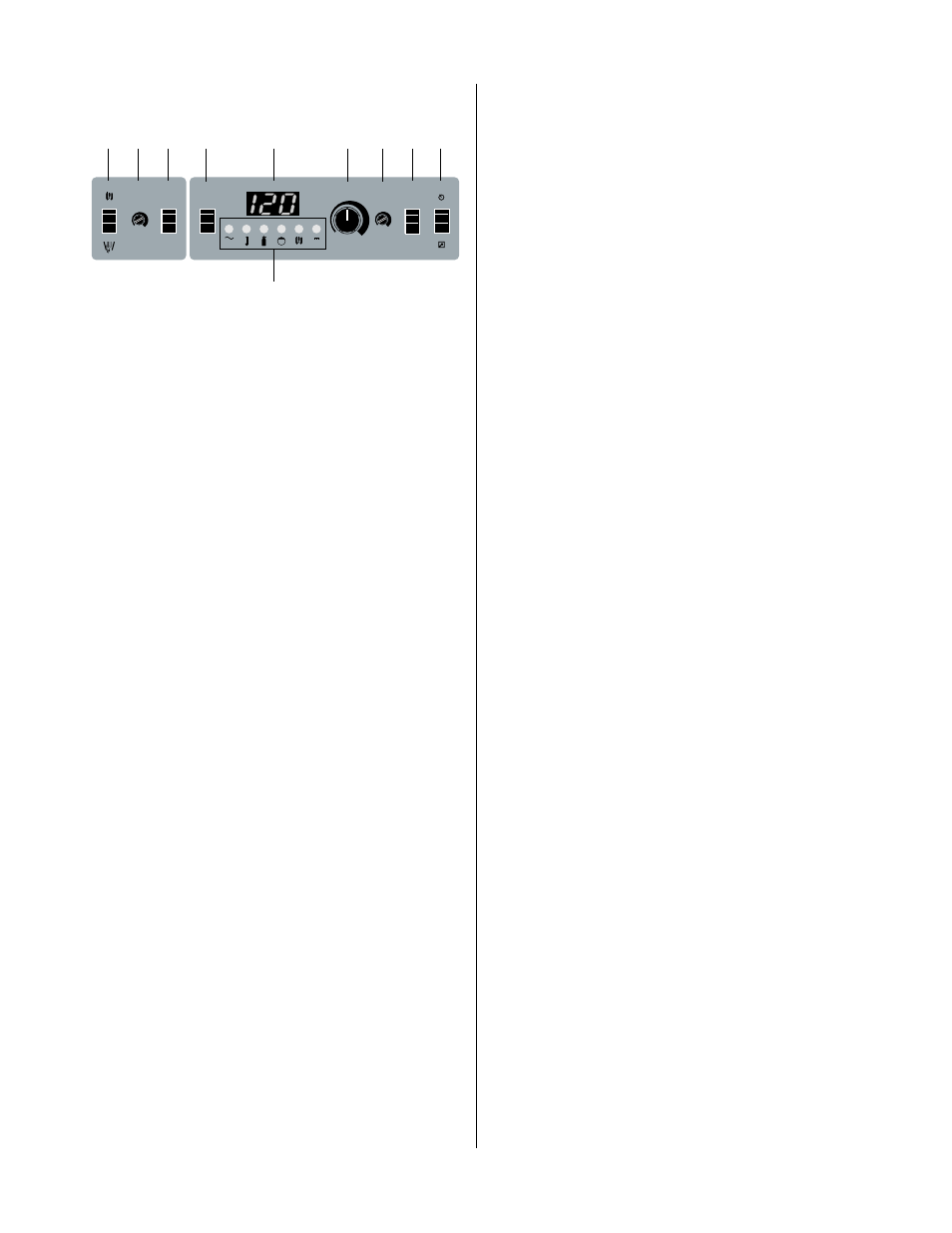

Figure 4-4 Front Panel Detail

For normal operation, the following lights should be

GREEN when you turn on the power:

• AC light

• TEMP light

• GAS light

• COOL light

5. Select Current Range:

Select the current range desired (#13):

High

5-150 amps

Low

0.5-15 amps

6. Select Remote/Panel Mode:

PANEL (#14) -Current control is adjusted by the front

panel pot. Preview with Weld Current Preview switch.

REMOTE (#14) -Current control is adjusted by exter-

nal remote device (compatible with Ultima-150 cur-

rent control circuit). The front panel pot is nonfunc-

tional in the remote mode. Current preview is

operational.

7. Adjust Current Limiter:

The Current Limiter Control (#12) limits the maximum

output current of the power source. The current lim-

iter prevents damage to the welding torch or consum-

ables and can also provide more precise current con-

trol.

For example, in range 5-150 (#13) with the maximum

current limiter (#12) set to 150 amps, the maximum

setting (fully clockwise) on the front panel current con-

trol (#11) would represent 150 amps, and the mini-

mum setting (fully counter clockwise) would repre-

sent approximately 5 amps.

If the current is controlled with either a remote device

or the front panel pot, the current will be 0-100% of

the range established by the current limiter (#12). If

the current is controlled with an external remote de-

vice, and the remote control is set at 50%, then ap-

proximately 75 amps weld current will be provided.

(Note that the current limiter pot is nonfunctional when

using remote analog voltage input signal.)

To set the Current Limiter, turn the current adjust con-

trol (#11) fully clockwise, make sure the PANEL/RE-

MOTE switch is in PANEL mode (#14), depress the

current PREVIEW switch (#8), and adjust the Current

Limiter (#12) with small screwdriver to desired maxi-

mum current output.

8. Preview Pilot Current:

Depress Pilot Arc Preview switch (#7). Set current

(#6), if applicable by using a small screwdriver. Nor-

mal range for pilot current is 5-8 amps.

9. Preview Weld Current:

Depress Current Preview switch (#8). If in PANEL

mode (#14), turn front panel control (#11). If in RE-

MOTE mode, adjust REMOTE Amp control pot to de-

sired level.

10. Pilot On:

Set the ON/SET Switch to ON (#5). Pilot arc will start

and Pilot Arc indicator light will be GREEN to indi-

cate pilot arc enabled.

11. Torch

Position torch over weld segment approximately

0.060" -0 .125" (1.2mm - 3mm).

12. Enable arc

Start the welding arc. (The method for enabling the

arc - foot control, user supplied switch, etc. depends

on user setup). When enabled, the DC indicator light

is GREEN. Welding Arc will transfer. Set proper weld

time, travel speed, and adjust current to obtain the

weld performance desired.

4.04 Torch Operation

A. Torch Parts Selection

The torch parts selected (shield cup, tip and electrode)

must correspond to the type of operation. See torch manual

for torch setup.