03 power source problems – Tweco 300 ACDC Arcmaster User Manual

Page 51

45

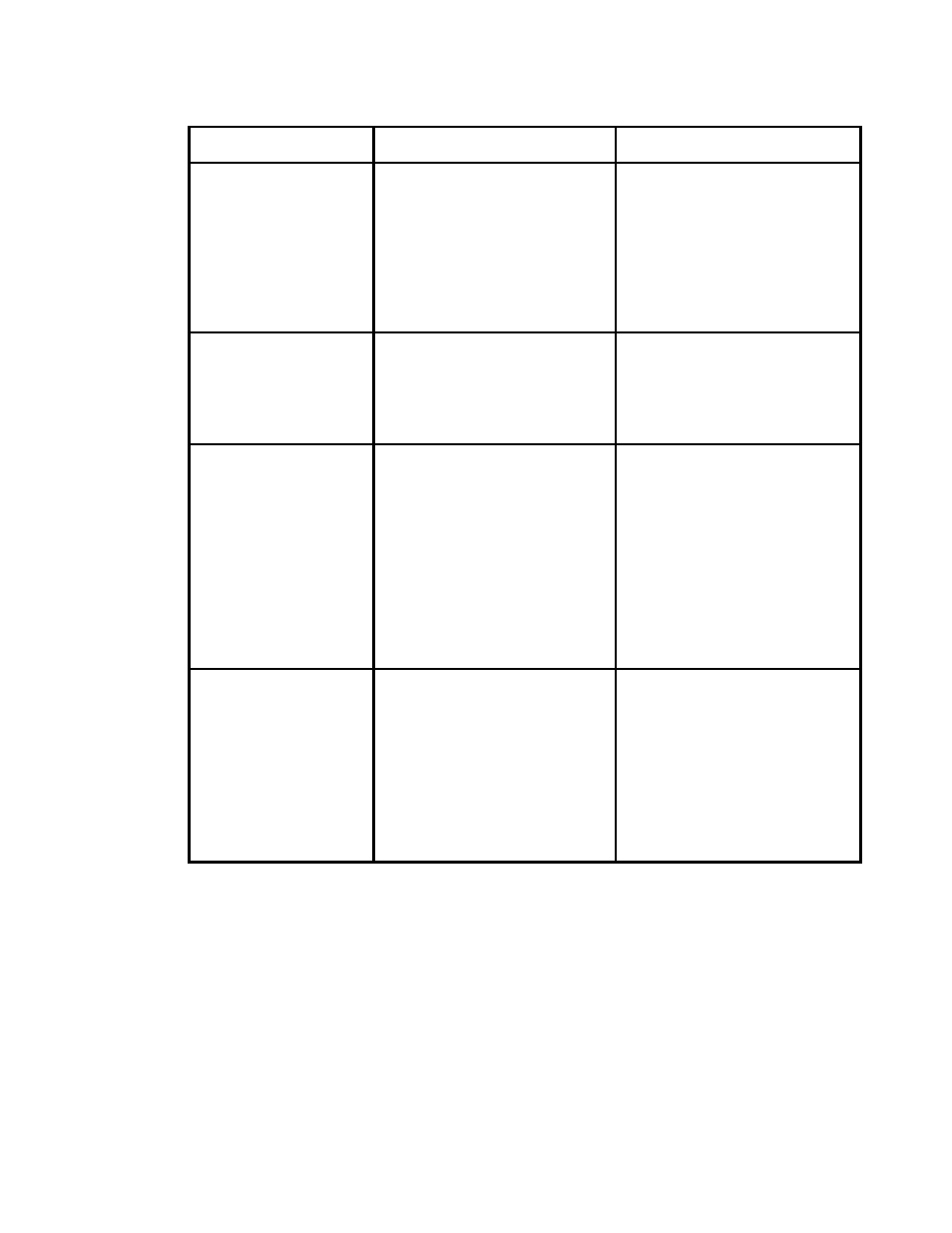

10.03 Power Source Problems

Description

Possible

Cause

Remedy

1 The welding arc

cannot be

established.

A

B

The Primary supply voltage

has not been switched ON.

The Welding Power Source

switch is switched OFF.

A

B

Switch ON the Primary supply

voltage.

Switch ON the Welding Power

Source.

C Loose connections internally.

C Have an accredited Thermal

Arc Service Agent repair the

connection.

2 Maximum

output

welding current can

not be achieved with

nominal Mains

supply voltage.

Defective control circuit.

Have an accredited Thermal

Arc Service Agent repair the

connection.

3 Welding

current

reduces when

welding.

A

B

C

D

E

Loose welding cable

connections.

Incorrect welding cable size.

Improper input connections.

Poor electrode condition.

Wrong welding polarity.

A

B

C

D

E

Tighten all welding cable

connections.

Use proper size and type

of cable.

Refer to Section 2.05 Electrical

Input Requirements.

Replace electrode.

Verify output torch

connections.

4 No gas flow when the

torch trigger switch

is depressed.

A

B

Gas hose is cut.

Gas passage contains

impurities.

A

B

Replace gas hose.

Disconnect gas hose from a

the rear of Power Source then

raise gas pressure and blow

out impurities.

C Gas regulator turned OFF.

C Turn gas regulator ON.

D Torch trigger switch lead is

disconnected or switch/cable

is faulty.

D Reconnect lead or repair

faulty switch/cable.

Table 10-3. Power Source Problems