01 tig welding problems – Tweco 300 ACDC Arcmaster User Manual

Page 47

41

SECTION 10. BASIC TROUBLESHOOTING

WARNING

There are extremely dangerous voltages and power levels present inside this product. Do not attempt to

open or repair unless you are an Accredited Thermal Arc Service Agent and you have had training in

power measurements and troubleshooting techniques.

If major complex subassemblies are faulty, then the Welding Power Source must be returned to an accredited

Thermal Arc Service Agent for repair.

The basic level of troubleshooting is that which can be performed without special equipment or knowledge.

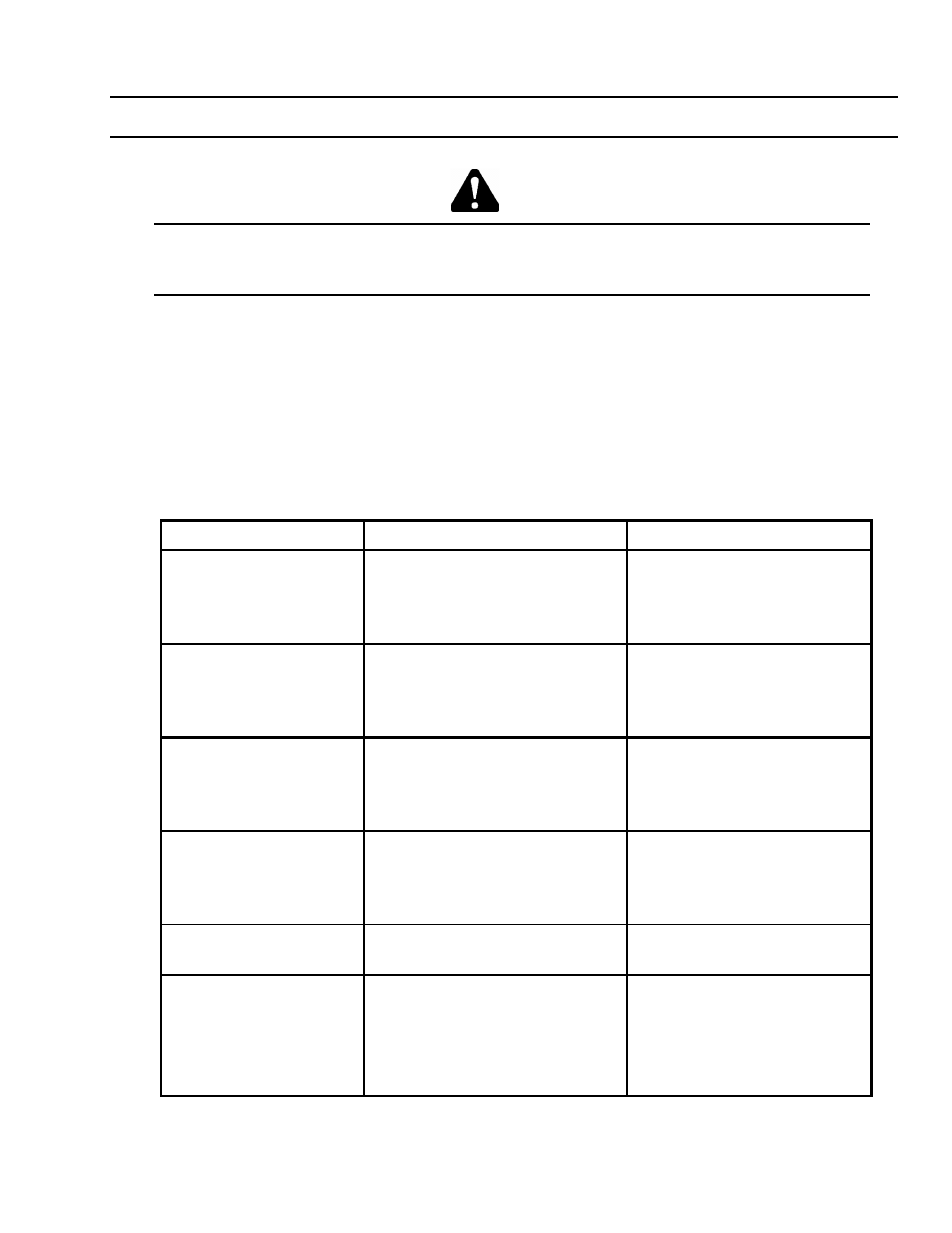

10.01 TIG Welding Problems

Weld quality is dependent on the selection of the correct consumables, maintenance of equipment and proper

welding technique.

Description

Possible

Cause

Remedy

1 Excessive bead build-up

or poor penetration or

poor fusion at edges

of weld.

Welding current is too low.

Increase weld current and/or

faulty joint preparation.

2 Weld bead too wide

and flat or undercut at

edges of weld or

excessive burn through.

Welding current is too high.

Decrease weld current.

3 Weld bead too small or

insufficient penetration

or ripples in bead are

widely spaced apart.

Travel speed too fast.

Reduce travel speed.

4 Weld bead too wide or

excessive bead build up

or excessive penetration

in butt joint.

Travel speed too slow.

Increase travel speed.

5 Uneven leg length in

fillet joint.

Wrong placement of filler rod.

Re-position filler rod.

6 Electrode melts when

arc is struck.

A Electrode is connected to the ‘+’

terminal.

A Connect the electrode to the

‘

−’ terminal.

B

WAVE BALANCE

is greater

than 50%.

B Reduced

WAVE BALANCE

to

below 50% or increase the

electrode size.

Table 10-1. TIG Welding Problems