08 welding parameters for aluminium, 09 welding parameters for steel – Tweco 300 ACDC Arcmaster User Manual

Page 43

37

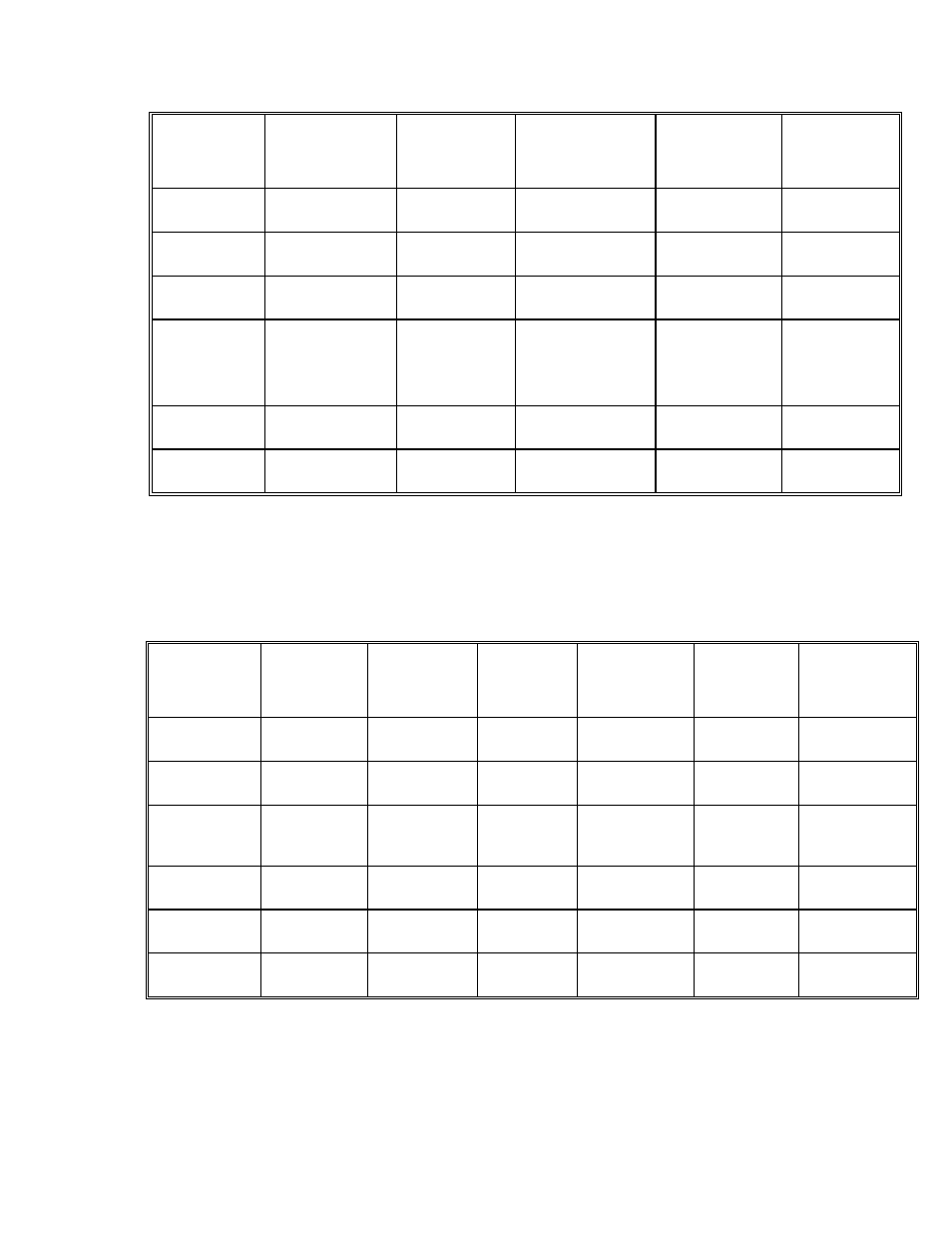

7.08 Welding Parameters for Aluminium

Table 7-7. AC TIG Welding Parameter

7.09 Welding Parameters for Steel

Base Metal

Thickness

DC Current

for Mild Steel

DC Current for

Stainless

Steel

Tungsten

Electrode

Diameter

Filler Rod

Diameter

(if required)

Argon Gas

Flow Rate

Liters/min

Joint Type

35-45 20-30

Butt/Corner

0.040”

1.0mm

40-50 25-35

0.040”

1.0mm

1/16”

1.6mm

5-7

Lap/ Fillet

45-55 30-45

Butt/Corner

0.045”

1.2mm

50-60 35-50

0.040”

1.0mm

1/16”

1.6mm

5-7

Lap/ Fillet

60-70 40-60

Butt/Corner

1/16”

1.6mm

70-90 50-70

1/16”

1.6mm

1/16”

1.6mm

7

Lap/ Fillet

80-100 65-85

Butt/Corner

1/8”

3.2mm 90-115 90-110

1/16”

1.6mm

3/32”

2.4mm

7

Lap/ Fillet

115-135 100-125

Butt/Corner

3/16”

4.8mm

140-165 125-150

3/32”

2.4mm

1/8”

3.2mm

10

Lap/ Fillet

160-175 135-160

Butt/Corner

¼”

6.4mm

170-200 160-180

1/8”

3.2mm

5/32”

4.0mm

10

Lap/ Fillet

Table 7-8. DC TIG Welding Parameters

Base Metal

Thickness

AC Current for

Aluminium

Tungsten

Electrode

Diameter

Filler Rod

Diameter

(if required)

Argon Gas Flow

Rate Liters/min

Joint Type

30-45 Butt/Corner

0.040”

1.0mm

35-50

0.040”

1.0mm

1/16”

1.6mm

5-7

Lap/ Fillet

40-60 Butt/Corner

0.045”

1.2mm

45-70

0.040”

1.0mm

1/16”

1.6mm

5-7

Lap/ Fillet

60-85 Butt/Corner

1/16”

1.6mm 70-95

1/16”

1.6mm

1/16”

1.6mm

7

Lap/ Fillet

125-150 Butt/Corner

1/8”

3.2mm

130-160

3/32”

2.4mm

1/8”

3.2mm

3/32”

2.4mm

10

Lap/ Fillet

180-225 Butt/Corner

3/16”

4.8mm 190-240

1/8”

3.2mm

1/8”

3.2mm

10

Lap/ Fillet

240-280 Butt/Corner

¼”

6.4mm 250-320

3/16”

4.8mm

3/16”

4.8mm

13

Lap/ Fillet