05 input power, 06 high frequency introduction – Tweco 300 ACDC Arcmaster User Manual

Page 22

16

3.05 Input Power

Each unit incorporates an INRUSH circuit and input voltage sensing circuit. When the MAIN CIRCUIT

SWITCH is turned on, the inrush circuit provides a pre-charging of the input capacitors. SCR’s in the

Power Control Assembly (PCA) will turn on after the input capacitors have charged to full operating voltage

(after approximately 5 seconds).

Note

Note the available input power. Damage to the PCA could occur if 460VAC or higher is applied.

The following 400 Primary Current recommendations are required to obtain the maximum welding

current and duty cycle from this welding equipment:

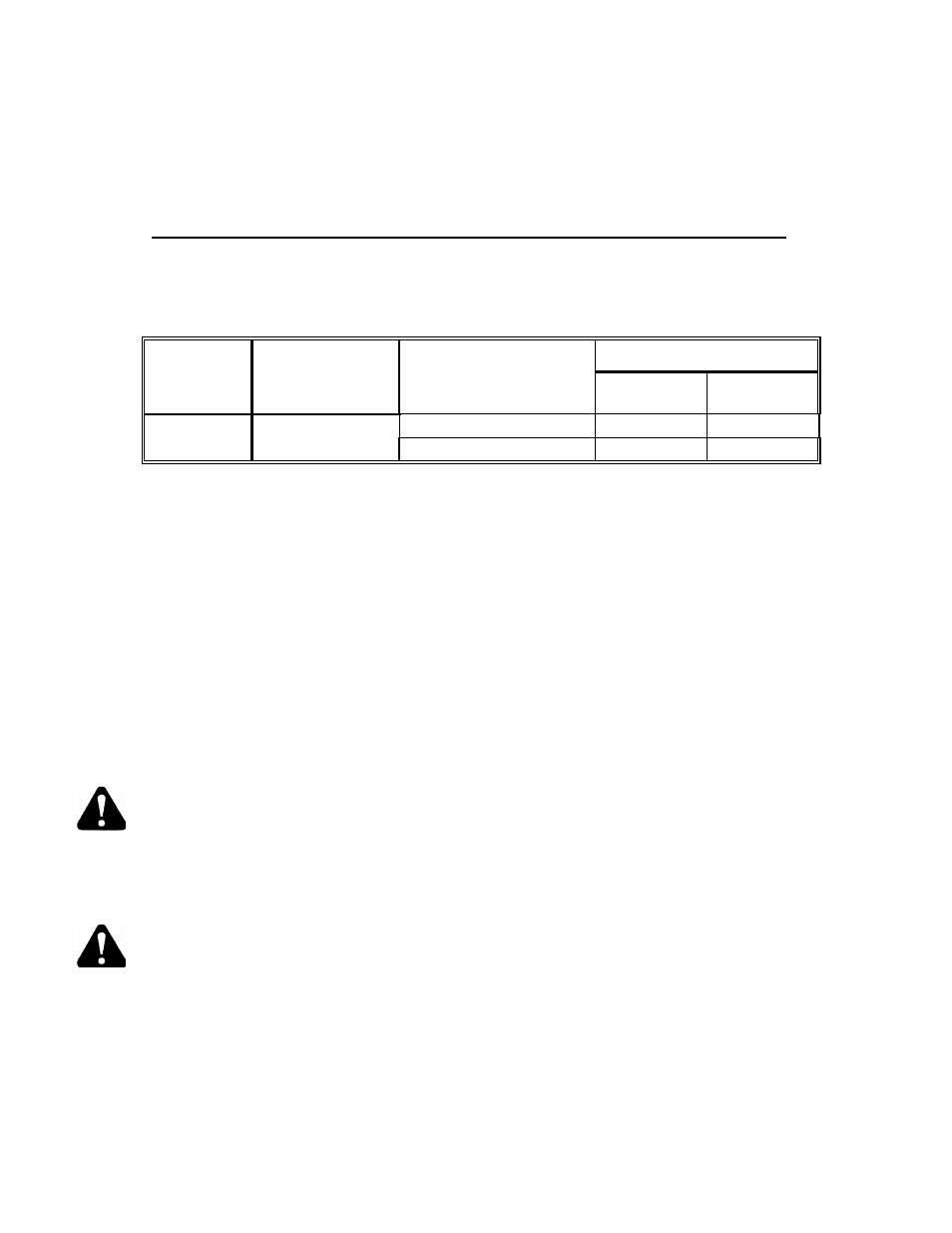

Table 3-2. 400V Primary Current Circuit sizes to achieve maximum current

The ARCMASTER 300 AC/DC is designed for use with a generator as an input power source. Contact an

accredited Thermal Arc service agent for the proper sizing and set-up recommendations of a generator

power source system. As a general rule, depending on the type of generator used, the generator capacity

should be twice the maximum rating of the welder.

3.06 High Frequency Introduction

The importance of correct installation of high frequency welding equipment cannot be over-emphasized.

Interference due to high frequency initiated or stabilized arc is almost invariably traced to improper

installation. The following information is intended as a guide for personnel installing high frequency

welding machines.

Warning

Explosive

s

The high frequency section of this machine has an output similar to a radio transmitter. The

machine should NOT be used in the vicinity of blasting operations due to the danger of premature

firing.

Computers

It is also possible that operation close to computer installations may cause computer malfunction.

Current & Duty Cycle

Model

Primary Supply

Lead Size (Factory

Fitted)

Minimum Primary

Current Circuit Size

(Vin/Amps)

TIG STICK

400/28

300 @ 40%

-

ArcMaster

300 AC/DC

4mm sq / 4

minimum

400/40

300 @ 40%