Arcmaster 200 ac/dc – Tweco 200 ACDC Arcmaster(April2006) User Manual

Page 50

ARCMASTER 200 AC/DC

10-2

April 13, 2006

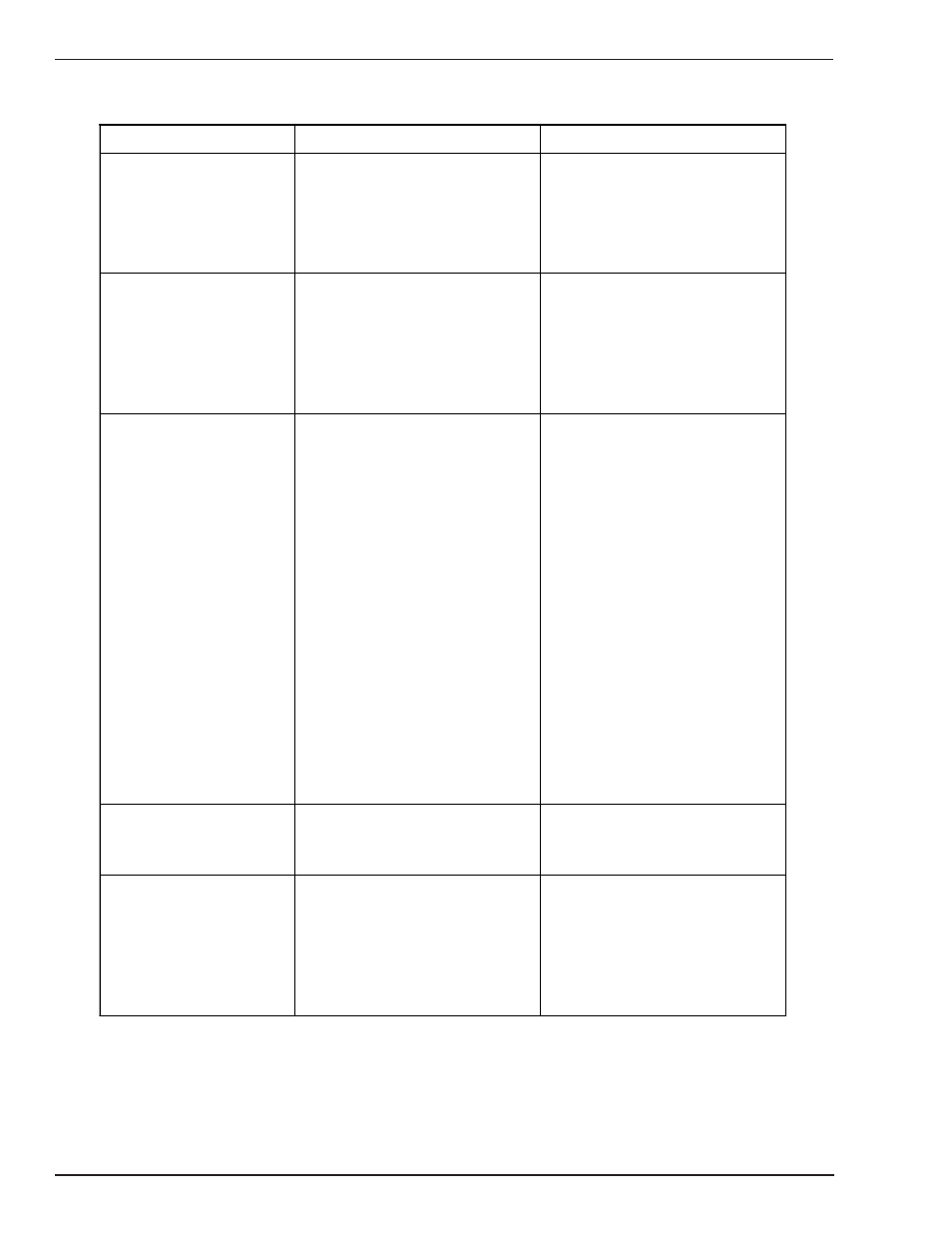

Description Possible

Cause

Remedy

6 Electrode melts when

arc is struck.

A

Electrode is connected to the

‘+’ terminal.

A Connect the electrode to the

‘

−’ terminal.

B

WAVE BALANCE

is greater

than 50%.

B Reduced

WAVE BALANCE

to below 50% or increase

the electrode size.

7 Dirty weld pool.

A

Electrode contaminated

through contact with work

piece or filler rod material.

A Clean the electrode by

grinding off the

contaminates.

B

Gas contaminated with air.

B Check gas lines for cuts

and loose fitting or change

gas cylinder.

8 Electrode melts or

oxidizes when an

arc is struck.

A

No gas flowing to

welding region.

A Check the gas lines for

kinks or breaks and gas

cylinder contents.

B

Torch is clogged with dust.

B Clean torch.

C

Gas hose is cut.

C Replace gas hose.

D Gas passage contains

impurities.

D Disconnect gas hose from

torch then raise gas pressure

and blow out impurities.

E

Gas regulator turned OFF.

E Turn ON.

F

Torch valve is turned OFF.

F

Turn ON.

G The electrode is too small

for the welding current.

G Increase electrode

diameter or reduce the

welding current.

H

WAVE BALANCE

is set

above 50%.

H Reduced

WAVE BALANCE

to below 50% or increase

the electrode size.

9 Poor weld finish.

Inadequate shielding gas.

Increase gas flow or

check gas line for gas

flow problems.

10 Arc flutters during

TIG welding.

A

Tungsten electrode is too

large for the welding current.

A Select the right size

electrode. Refer to Basic

TIG Welding guide.

B Absence of oxides in the

weld pool.

B Refer Basic TIG Welding

Guide for ways to reduce

arc flutter.

Table 10-1 (continued): TIG Welding Problems