05 guide for selecting filler wire diameter, 06 shielding gas selection, Arcmaster 200 ac/dc – Tweco 200 ACDC Arcmaster(April2006) User Manual

Page 43

ARCMASTER 200 AC/DC

April 13, 2006

7-3

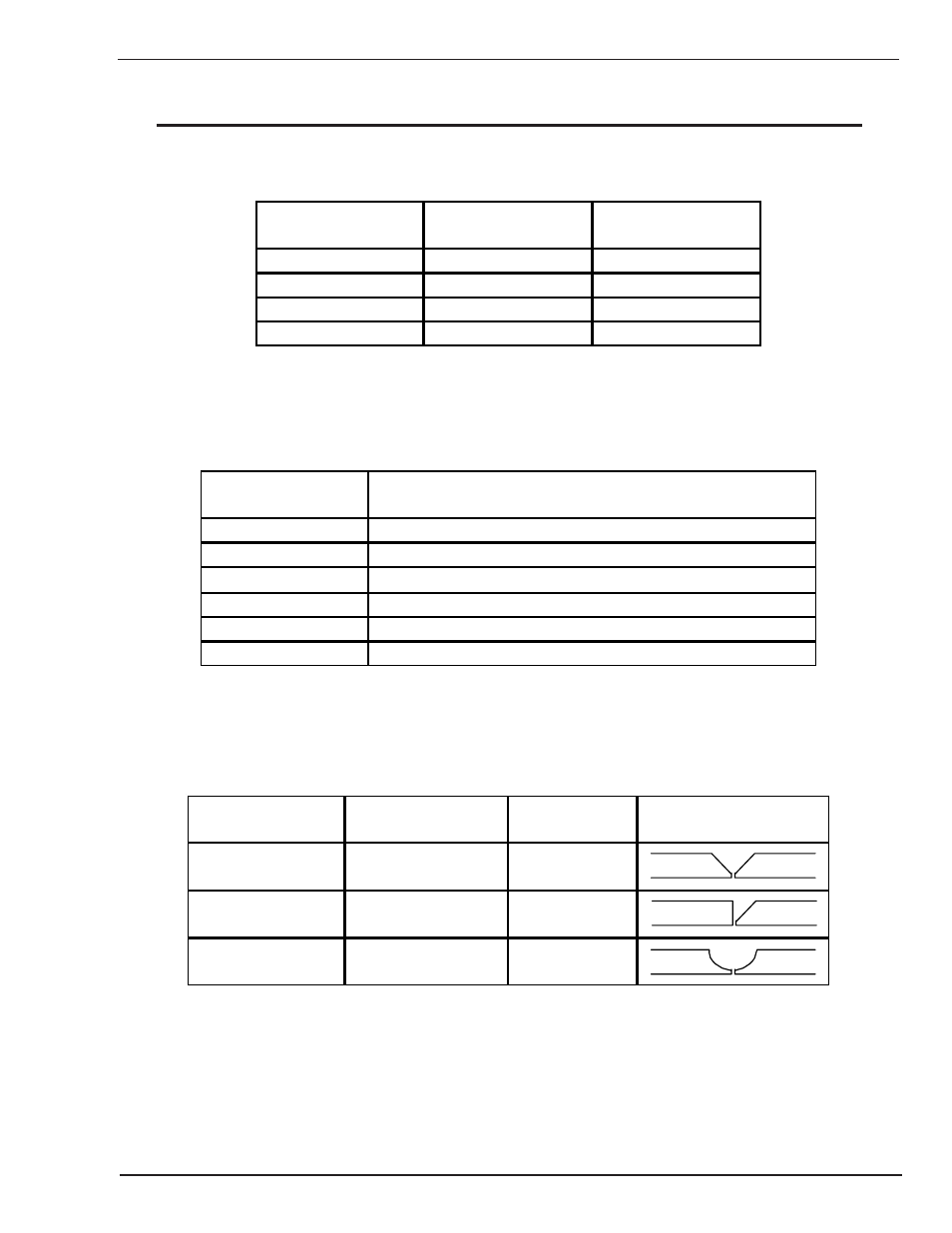

7.05 Guide for Selecting Filler Wire Diameter

NOTE

The filler wire diameter specified in Table 7-4 is a guide only, other diameter wires may be used according

to the welding application

AC Current Range

DC Current Range

(Amps)

(Amps)

1/16” (1.6 mm)

30 - 95

20 - 90

3/32” (2.4 mm)

125 - 160

65 - 115

1/8” (3.2 mm)

180 - 240

100 - 165

3/16” (4.8 mm)

220 - 320

200 - 350

Filler Wire Diameter

Table 7-4: Filler Wire Selection Guide

7.06 Shielding Gas Selection

Shielding Gas

Argoshield is a registered trademark of BOC Gases Limited.

Aluminium & alloys

Welding Argon, Argoshield 80T, 81T

Carbon Steel

Welding Argon

Stainless Steel

Welding Argon, Argoshield 71T, 80T, 81T

Nickel Alloy

Welding Argon, Argoshield 71T

Copper

Welding Argon, Argoshield 81T

Titanium

Welding Argon, Argoshield 80T, 81T

Alloy

Table 7-5: Shielding Gas Selection

7.07 TIG Welding Parameters for Low Carbon & Low Alloy Steel Pipe

Current Range DC

Amperes

Thoriated 2%

3/32” (2.4 mm)

Thoriated 2%

3/32” (2.4 mm)

Thoriated 2%

3/32” (2.4 mm)

Electrode Type &

Diameter

Filler Rod for

Root Pass

Joint Preparation

120 - 170

Yes

100 - 160

Yes

90 - 130

No

Table 7-6: TIG Welding Parameters for Low Carbon & Low Alloy Steel Pipe