08 welding parameters for aluminum, 09 welding parameters for steel, Arcmaster 200 ac/dc – Tweco 200 ACDC Arcmaster(April2006) User Manual

Page 44

ARCMASTER 200 AC/DC

7-4

April 13, 2006

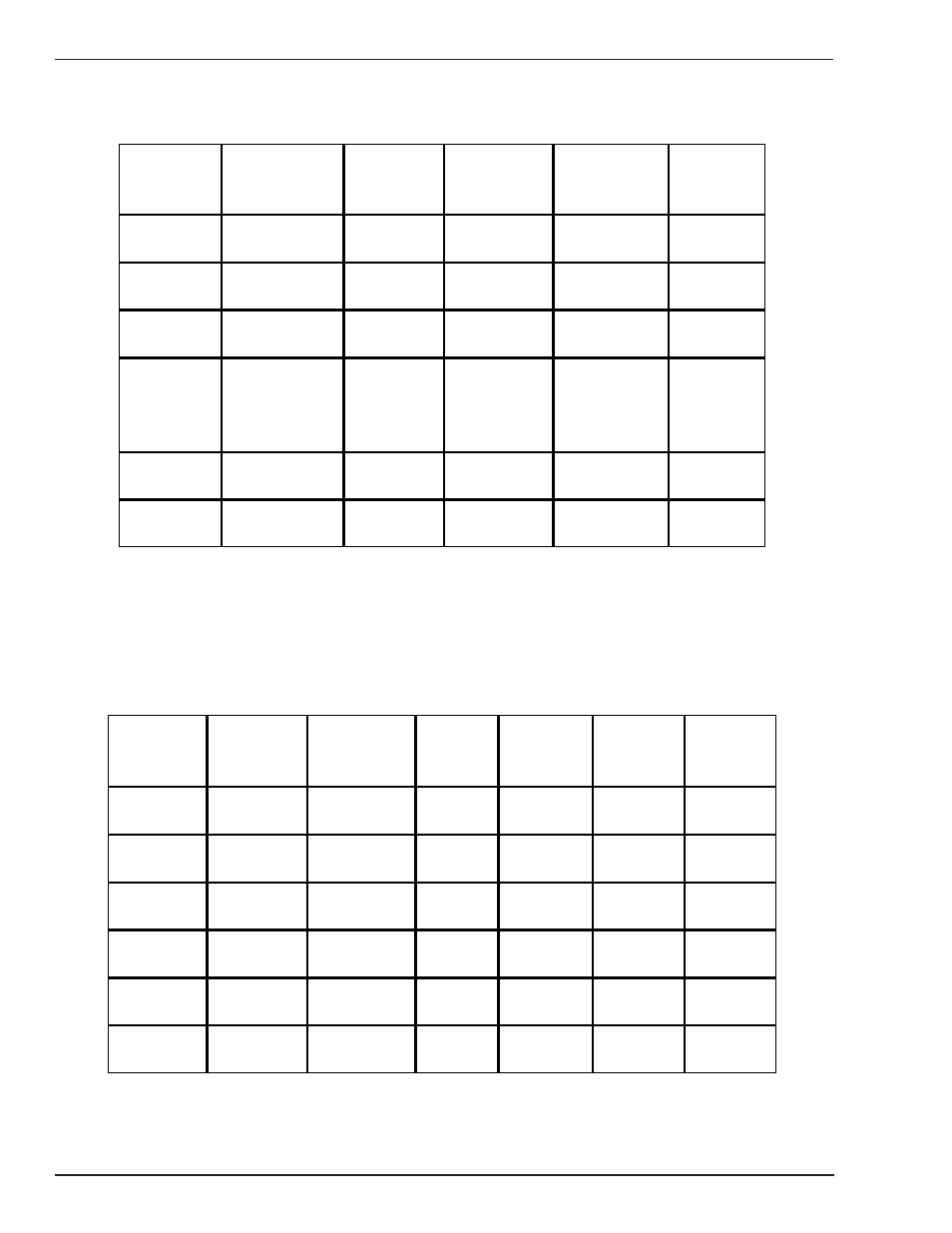

7.08 Welding Parameters for Aluminum

Filler Rod

Diameter

(if required)

0.040”

30-45

0.040”

1/16”

Butt/Corner

1.0mm

35-50

1.0mm

1.6mm

Lap/ Fillet

0.045”

40-60

0.040”

1/16”

Butt/Corner

1.2mm

45-70

1.0mm

1.6mm

Lap/ Fillet

1/16”

60-85

1/16”

1/16”

Butt/Corner

1.6mm

70-95

1.6mm

1.6mm

Lap/ Fillet

1/8”

3/32”

3/32”

3.2mm

2.4mm

2.4mm

1/8”

3.2mm

3/16”

180-225

1/8”

1/8”

Butt/Corner

4.8mm

190-240

3.2mm

3.2mm

Lap/ Fillet

¼”

240-280

3/16”

3/16”

Butt/Corner

6.4mm

250-320

4.8mm

4.8mm

Lap/ Fillet

10

13

Joint Type

Butt/Corner

Lap/Fillet

5-7

5-7

7

10

Argon Gas

Flow Rate

Liters/min

125-150

130-160

Base Metal

Thickness

AC Current for

Aluminum

Tungsten

Electrode

Diameter

Table 7-7: AC TIG Welding Parameters

7.09 Welding Parameters for Steel

Filler Rod

Diameter

(if required)

0.040”

35-45

20-30

0.040”

1/16”

Butt/Corner

1.0mm

40-50

25-35

1.0mm

1.6mm

Lap/ Fillet

0.045”

45-55

30-45

0.040”

1/16”

Butt/Corner

1.2mm

50-60

35-50

1.0mm

1.6mm

Lap/ Fillet

1/16”

60-70

40-60

1/16”

1/16”

Butt/Corner

1.6mm

70-90

50-70

1.6mm

1.6mm

Lap/ Fillet

1/8”

80-100

65-85

1/16”

3/32”

Butt/Corner

3.2mm

90-115

90-110

1.6mm

2.4mm

Lap/ Fillet

3/16”

115-135

100-125

3/32”

1/8”

Butt/Corner

4.8mm

140-165

125-150

2.4mm

3.2mm

Lap/ Fillet

¼”

160-175

135-160

1/8”

5/32”

Butt/Corner

6.4mm

170-200

160-180

3.2mm

4.0mm

Lap/ Fillet

Base Metal

Thickness

DC Current

for Mild

Steel

DC Current for

Stainless

Steel

Tungsten

Electrode

Diameter

7

10

10

Joint Type

Argon Gas

Flow Rate

Liters/min

5-7

5-7

7

Table 7-8: DC TIG Welding Parameters