Cut characteristics, Page – Tweco Dynamics Automation User Manual

Page 7

Cut characteristics

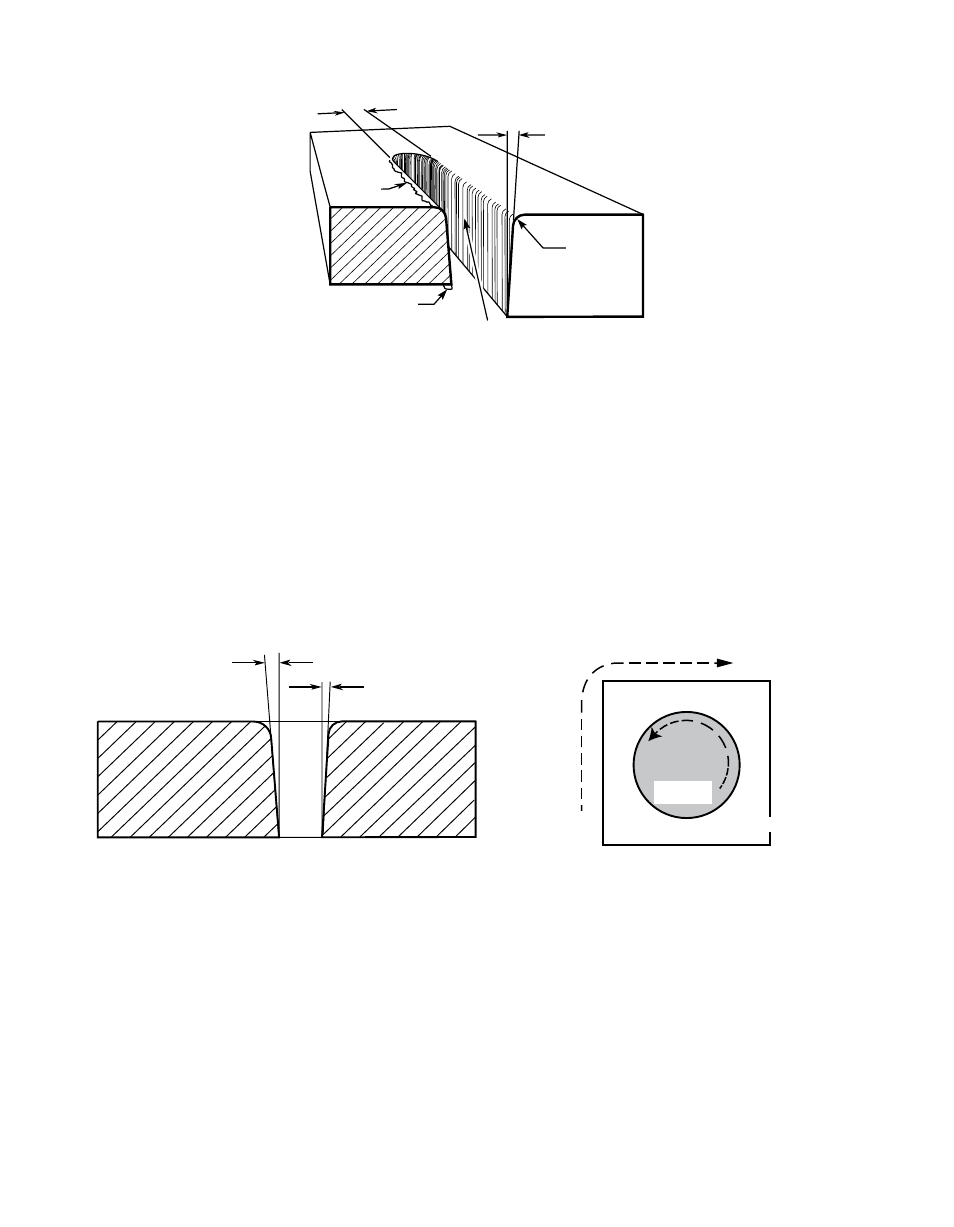

Direction of cut

– The plasma has a clockwise swirl as it exits the torch tip. Considering the

direction of torch travel, the right side of the cut will always show less bevel and top edge

rounding than the left side. Program cuts so that the right side will be on the finished part and

the left side will be scrap.

Top edge rounding

– Caused by the heat of the plasma arc at the top surface of the cut.

Proper torch height control can minimize or eliminate top edge rounding. Excessive top

edge rounding is often a sign that torch cutting height should be lower.

Top spatter

– Top spatter is caused by fast cutting or by too high a torch height setting.

Reducing cut speed or lowering torch cutting height will reduce top spatter. Top spatter is

easy to remove.

Bottom dross

– Molten metal may build up on the bottom of the plate. Faster cut speeds

reduce bottom dross as less material is melted. Bottom dross that is easy to remove is an

indication of slow cutting speed. Bottom dross that is difficult to remove or requires grinding

is an indication of too fast cut speed.

Cut Surface

– Cut surface is influenced by process and positioner precision more than by other

parameters. For smoothest cut face on different materials, use: mild steel – oxygen plasma

stainless < ¾’ – nitrogen / WMS

> ¾” – H35 / nitrogen

aluminum < ¾’ – nitrogen /WMS

> ¾” – H35 / nitrogen

Right Side

Cut Angle

Left Side

Cut Angle

A-00512

Scrap

Clockwise

Counter-

Clockwise

Art # A-04182

Workpiece

Scrap

Kerf Width

Cut Surface

Bevel Angle

Top Edge

Rounding

Cut Surface

Drag Lines

Dross

Build-Up

Top

Spatter

A-00007

page