Consumable parts life, Page – Tweco Dynamics Automation User Manual

Page 6

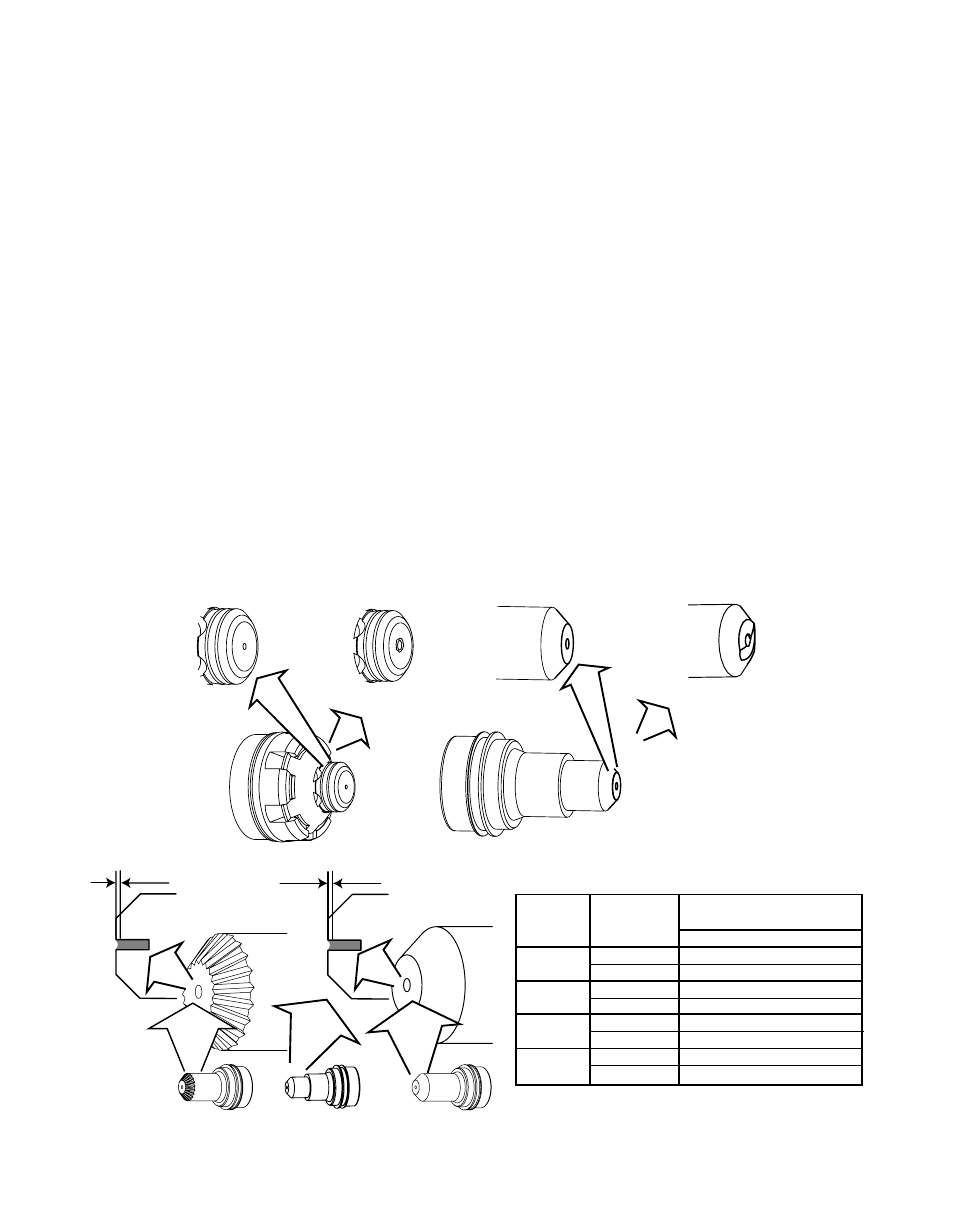

Tips and electrodes wear under normal usage. Tips and electrodes should be

changed before failure to avoid damaging the other consumable parts or the material to be

cut. Optimum life will vary according to specific cutting conditions. Keep a count of cuts

per set of tip and electrode in a given application to establish the most effective time to

change consumable parts sets. The pilot arc is more erosive to the tip and electrode than

the cutting arc is, so an application that demands more pilot and pierce sequences will erode

consumable parts faster than an application that uses longer cuts but fewer arc starts.

Tip

– Tips wear as the arc erodes the tip orifice. When the tip is no longer round or has

become enlarged, it should be replaced. Tip life is best when cuts are made at optimum

speed. Cutting too fast or too slow causes the arc to bend and biases erosion, resulting

in an orifice that is oval shaped.

Electrodes

– The electrode wears from the hafnium or tungsten insert at the end of the

electrode. The face of the insert is liquefied by the heat of the arc and droplets erode from

the insert as cutting progresses. Proper gas flow will support longer electrode life.

An electrode should be replaced when the electrode insert is pitted to a depth of 1/16 inch

(see chart below).

Consumable Parts Life

Amperage Plasma Gas Recommended Wear Depth

for Replacement

Inch

mm

O2 0.04

1

Air

0.04

2

O2 0.04

1

Air

0.08

2

O2 0.04

1

Air

0.08

2

O2 0.04

1

H35 0.08

2

30

50

70

100

Torch

Electrodes

Art # A-04704_AB

Good Electrode

Worn Electrode

Good Tip

Worn

Tip

Art # A-04745_AB

Replace the Gas Distributor if it is charred or cracked

Replace the Gas Disributor if the flange is damaged in any way

Replace the tip and/or electrode if they are worn

page