Auto-cut 300 xt – Tweco 300 XT Auto-Cut 380V User Manual

Page 130

AUTO-CUT 300 XT

A-��

APPENDIX

Manual 0-5261

104

Transfer Lost

Arc transferred to metal for at least 50 ms. then went out.

Causes for 104 code:

• Cut demand set much lower than recommended for torch parts, i.e. 100A consumables in torch but cut

current set for 30 or 50A (or zero). Current may be too low to keep arc on.

• Torch standoff too high for cutting process being used.

• Plasma gas flow too low due to a leak somewhere between the plasma regulator or the DPC 3000 and the

torch. Check for leaks.

• Remote analog current control switches set wrong.

o If remote analog current control is being used, SW8-2 (CCM CPU PCB) is on and SW11 (CCM I/O

PCB) is set to “A” (down) position, but no analog voltage connected to TB1-10 or J15-30 (CNC cable)

then cut demand will be zero, pilot will be weak, depending on torch height it may still transfer but

will immediately go out.

o If remote analog current control is not being used but either SW11 is set to the down position or SW8-2

is on also results in zero cut demand.

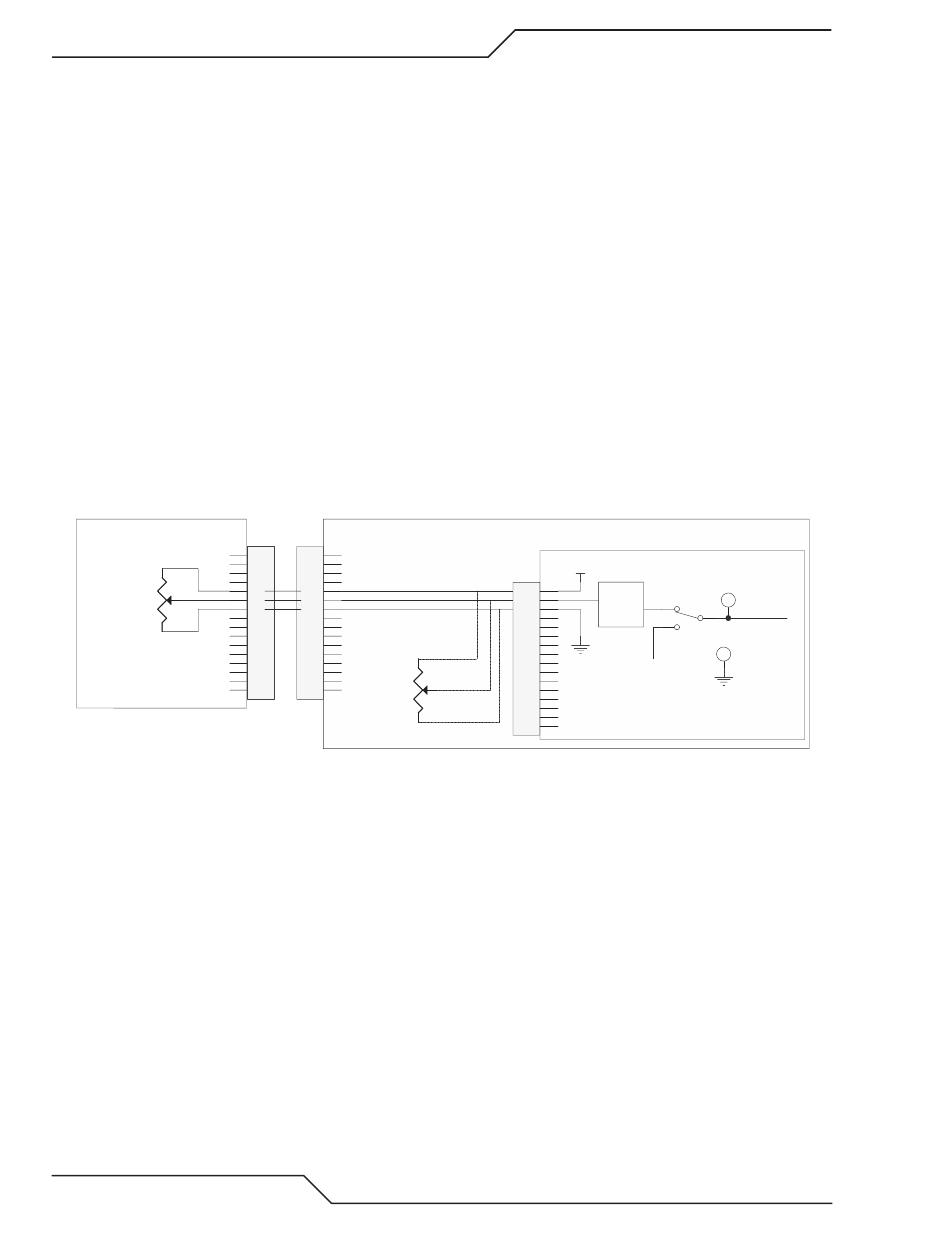

o If system is Auto-Cut XT, current control is an analog voltage from the GCM 1000 XT or the AC 200

XT front panel pot. The current control setting will be shown on the front panel 4 digit display. SW8-

2 should be off and SW11 set to up position. With pot at max, check for 3.3V on CCM I/O PCB TP9

(TP1 common). While turning the pot toward minimum TP9 voltage should vary linearly to zero V.

Art # 12309

2

1

3

SW11

TP9

TP1 GND

0-3.3VDC

GND

Divide

by 3.

From Remote

analog Current

Control

CCM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J26

GND

+10.0V

R1

10K

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J55

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J56

GCM 1000 XT

(125)

(126)

(127)

Auto-Cut XT Power Supply

(AC 300 XT)

R1

10K

AC 200 XT

105

Not Used. This is one of the reserved codes from the earlier product.

106

Pilot Timeout, no Transfer

Pilot time is limited to either 0.085 seconds (85 ms.) with CCM SW8-1 off (default for pierce starting) or 3 seconds

with SW8-1 on (used for cutting over holes, expanded metal, etc.). Arc must transfer before pilot time ends.

Code 106 is set if no arc transfer (current in work lead) was sensed before pilot timed out. If the unit does not

detect pilot current the arc starter will operate up to 15 seconds then set the 102 code. If you are getting 106 there

is pilot current somewhere. If it’s not visible perhaps it’s inside the consumables or following some other part.

Causes for 106 code:

No Pilot Visible:

• Pilot inside the consumables

Visible Pilot:

• First the obvious, make sure the work lead is connected both to the work and the power supply. Also

make sure the work itself is making good electrical contact with cutting table. If rusty or painted metal,

you may need to clean a spot and attach the work lead directly to the metal.

• Torch too far from work.