Appendix 18: advanced troubleshooting, Auto-cut 300 xt – Tweco 300 XT Auto-Cut 380V User Manual

Page 120

AUTO-CUT 300 XT

A-3�

APPENDIX

Manual 0-5261

APPENDIX 18: ADVANCED TROUBLESHOOTING

System Overview

The Auto-Cut 200 & 300 XT & Ultra-Cut 100, 200, 300 & 400

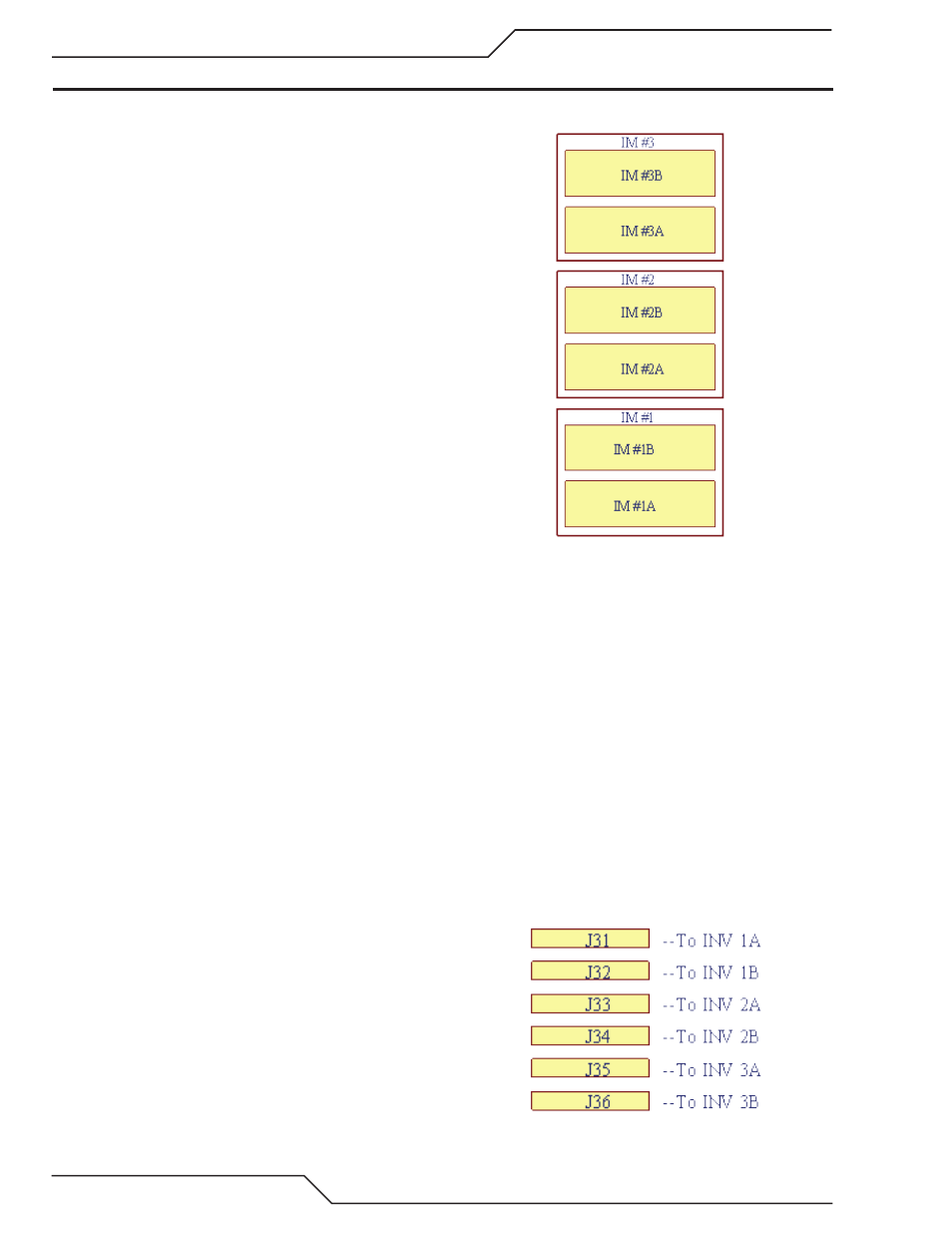

XT power supplies include one, two or three inverter mod-

ules (IM). Each IM may have either 1 or 2 inverter sections

designated A or B sections. The IMs are mounted one over

the other numbered from bottom to top. The sections are

also designated from bottom to top with section A being on

the bottom of each module. An IM with one section is con-

sidered to be a ½ or “partial” module with the upper or “B”

section missing. ½ modules are used with the 200A & 300A

power supplies and will always be in the middle position.

IMs with 2 sections are considered to be “full” modules.

Each inverter section can supply up to 67A but does not do

so in all configurations:

A 400A unit uses 6 sections. 400A / 6 = 66.67A per section.

A 300A unit uses 5 sections. 300A / 5 = 60A per section.

A 200A unit uses 3 sections. 200/3 = 66.67A per section.

A 100A unit uses 2 sections. 100/2=50A per section.

Unit configurations.

With the exception of the AC 200 XT all other units have the

same chassis with room for up to 3 IMs. The unused areas

have blank panels filling the empty locations which are

required for proper air flow. A 100A system uses 1 full IM;

200A uses 1 and ½ modules with a full module in the bottom

location and a ½ module in the middle position. A 300A

unit has full modules top and bottom with the ½ module

in the middle location. The AC 200 XT has only the bottom

and middle locations for IMs. An internal Arc Starter and

Gas Control are located in the place of the 3rd or upper IM.

Inverter module cooling.

The power semiconductors of the inverter modules are liq-

uid cooled allowing us to get more power in a smaller area

and at lower cost. Each IM has a liquid cooled heatsink or

“cold plate” shared by the 2 inverter sections. The magnetic

components, transformers and inductors, are air cooled and

mounted on the back side of the IMs where they are exposed

to high volumes of air flow from the cooling fans whose air

also cools liquid coolant in the radiator or heat exchanger.

It is important that lower right side panel be in place or the

air flow will not be proper for cooling the magnetics.

Inverter control.

The inverter sections are operated as separate inverters

whose outputs are connected in parallel. They are controlled

independently from the Command and Control Module

(CCM) which is the “brains” of the system. Each inverter

section has a separate ribbon cable connected to it coming

from the CCM which has 6 connectors, J31 – J36 correspond-

ing to the inverter sections 1A through 3B. The ribbon cables

are labeled on the inverter ends as INV with the number and

Art # 12299

Art # 12300