07 connect work cable, 07 connect work cable -12, D. routing of torch leads – Tweco 200 Auto-Cut User Manual

Page 36

Manual No. 0-4805 Auto-Cut 200

3-12

INSTALLATION

D. Routing Of Torch Leads

1. To minimize RF interference, position torch leads as far as possible from any CNC components, drive motors,

control cables, or primary power lines. If cables have to pass over torch leads, do so at an angle. Do not run the

plasma control or other control cables in parallel with the torch leads in power tracts.

2. Keep torch leads clean. Dirt and metal particles bleed off energy, which causes difficult starting and increased

chance of RF interference.

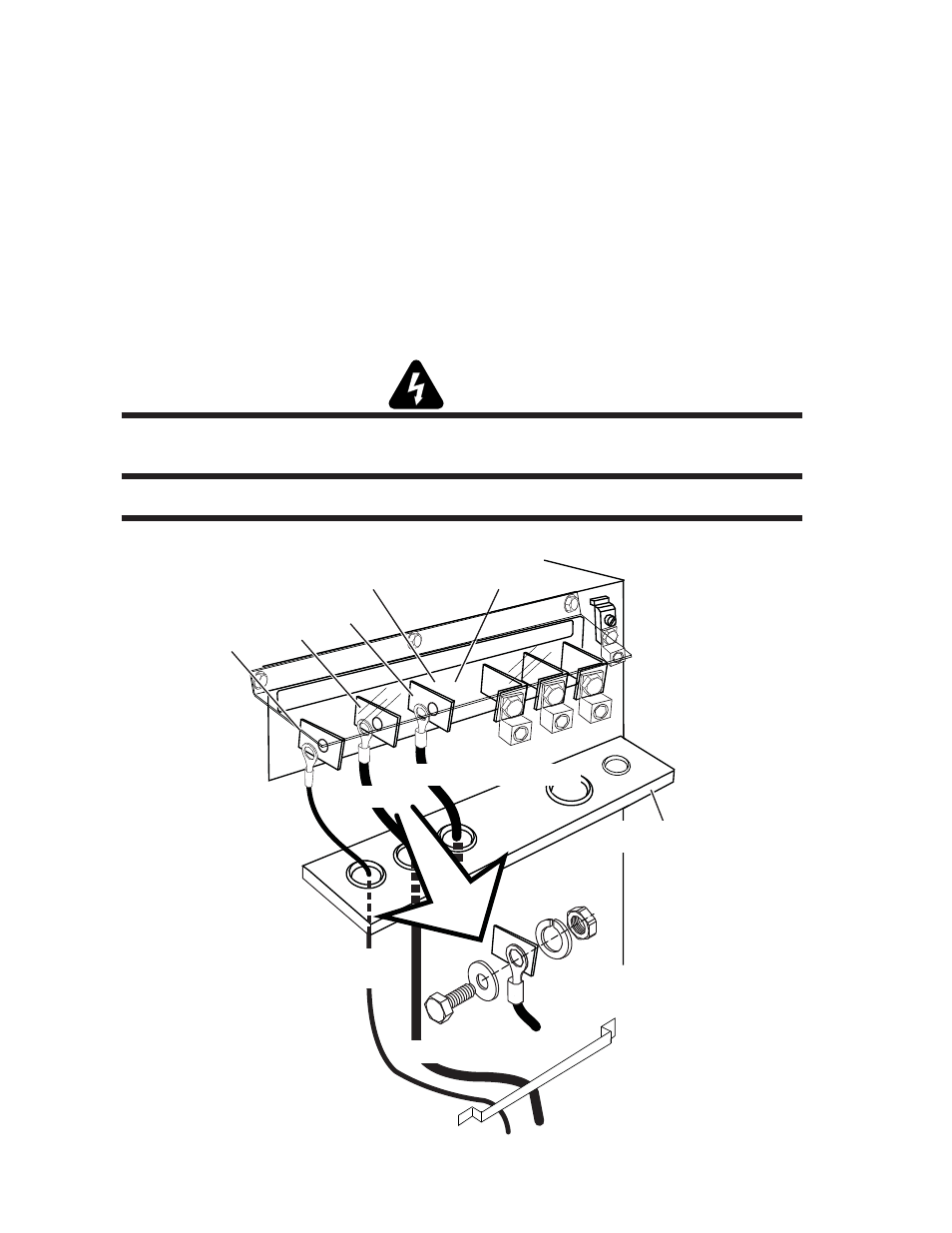

3.07 Connect Work Cable

1. Pass the end of the work cable upward through the leads bracket at the bottom of the power supply rear

panel, then up through the opening in the connections cover support panel.

2. Refer to the illustration. Connect the lead as shown. Tighten securely. Do not overtighten.

WARNINGS

Ensure that lead attachment hardware is properly sized. Excess length may cause damage if hardware contacts

other parts of the system.

The clear connections cover must remain in place.

PILO

T

WORK

TORCH

Connection Panel

AC INPUT

L1

L2

L3

Work Lead

Torch Lead - To Remote Arc Starter

Work

Torch

Lead Connection Detail

Connections Cover

Support Panel

Art # A-07660_AB

Connections Cover

Pilot

To Cutting Table

Leads Bracket

Pilot Lead -

To Remote Arc Starter