Ultra-cut 100, Gcm 2010 – Tweco 100 Ultra-Cut User Manual

Page 72

OPERATION

4-6

Manual No. 0-4748

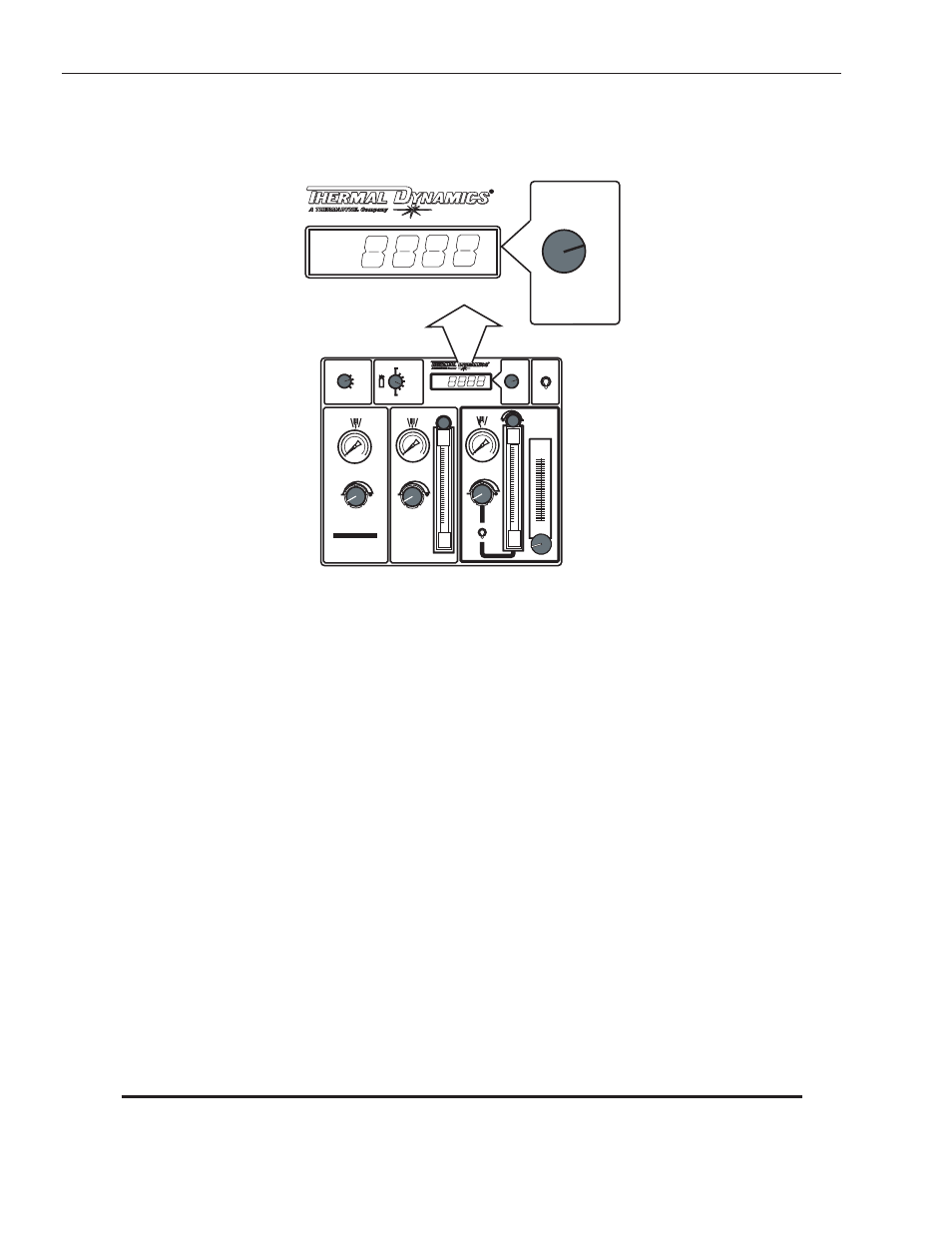

ULTRA-CUT 100

4. Current Control

Adjusts the output current of the power supply.

High Precision

Plasma Cutting System

PREFLOW

H

2

O

MIST

PLASMA

SHIELD

PRESSURE

PLASMA

POWER SUPPLY

GAS

FLOW

High Precision

Plasma Cutting System

ENABLE

DISABLE

GAS

MODE

RUN

SET PREFLOW

SET PLASMA

& SHIELD

TEST

O2 - AIR

O2 - O2

H35 -N

2

F5 - N

2

AIR - AIR

N

2 -

H

2

O

N

2 -

N

2

9

9

Art # A-04767

GCM

2010

5. Plasma Power Supply Enable / Disable Switch

The DISABLE position removes input power from the Power Supply inverters, disables the coolant pump and

fan, the pilot contactor & HF and removes AC power from the gsa control solenoids shutting off all gas flow.

When the switch is returned to the ENABLE position an automatic gas purge is started and then the system is

returned to normal operation under control of the CNC device.

6. PREFLOW Control Knob and Pressure Gauge

Used to set preflow gas pressure and flow. MODE switch must be in SET PREFLOW position.

7. PLASMA and SHIELD Control Knobs, Pressure Gauges and Flow Meter

Used to set plasma and shield gas pressures and flows. Mode switch must be in SET PLASMA & SHIELD

position.

8. Gas Pressure Flow Switch

At lower flow rates shield gas pressure is first set per the cut charts then the flow is set using the flow meter

with the GAS switch set in the FLOW position. Some torch parts require higher flow rates that execeed the

capacity of the flow meter. In that case, Gas switch is set in the PRESSURE position and the regulator and

gauge is used to set pressure per the cut charts when no “Ball” setting is shown.

9. H

2

O Mist Control Knob and Flow Meter

Used to set water flow rate. MODE switch must be in SET PLASMA & SHIELD position. GAS selection switch

must be in N

2

-H

2

O position.

NOTE

Water mist is not used in all applications.