Tweco SC11 User Manual

Page 26

OPERATION

4-2

Manual 0-2556

After receiving a start signal with one of the FIND

HT modes selected, FIND HT indicator ON, the

standoff control equipment lowers the torch from the

retracted position until it contacts the metal to be cut.

The standoff equipment then lifts the torch back up

the distance above the plate set by the adjustable

PIERCE HT control from nearly zero to over 1/2".

When doing a piercing operation it is best to start

from the highest possible position to minimize splat-

ter onto the end of the torch. Splatter onto the torch

shield and tip can block the cutting tip orifice.

6. PIERCE DELAY (sec) Control

The PIERCE DELAY controls the arc transfer or mo-

tion (OK-To-Move) start signals to the cutting ma-

chine. This delay allows time for the arc to pierce

through the material. The delay time is adjustable

from zero to over three seconds.

NOTE

The cutting machine controller may also have a

motion delay which will add to the total delay, if so

it should be set to zero.

Height regulation will be inhibited during the delay

time selected.

7. END OF CUT RETRACT (%) Control

The END OF CUT RETRACT controls the raising (re-

tracting) of the torch from zero to 100% of the selected

setting of the END OF CUT RETRACT (%) Control.

With one of the FIND HT modes selected, FIND HT

indicator ON, the torch is raised at the end of a cut

operation when the start signal is removed. The

amount of time that it takes to raise the torch can be

reduced by not retracting the torch fully, if not re-

quired.

8. T.H.C. ACTIVE Indicator

The T.H.C. (Torch Height Control) ACTIVE indica-

tor turns ON when the height is under active con-

trol. The T.H.C. ACTIVE indicator turns OFF when

no initial arc transfer signal is received, standoff in-

hibit (corner slowdown - CSD) signal is on, an arc

voltage outside the regulation limits of 65 to 195 volts,

or the voltage is rising rapidly.

The voltage rising rapidly can be caused by cutting

over a kerf, other hole, or the edge of the plate being

cut.

When the T.H.C. ACTIVE indicator is OFF the stand-

off is not being regulated during that time.

9. TORCH UP/DN Pushbuttons and Indicators

The momentary TORCH UP/DN pushbutton

switches allow setting the torch position manually.

Pressing the TORCH UP switch will cause the UP in-

dicator to turn ON. The DN (Down) indicator turns

ON if the TORCH DN pushbutton is pressed.

The manual control may be used to set initial height

when the FIND HT indicator is OFF. The controls

can also be used to adjust the standoff when the

AUTO HT indicator is OFF.

The manual controls should not be used while cut-

ting if the AUTO HT indicator is ON (see ARC VOLTS

Control).

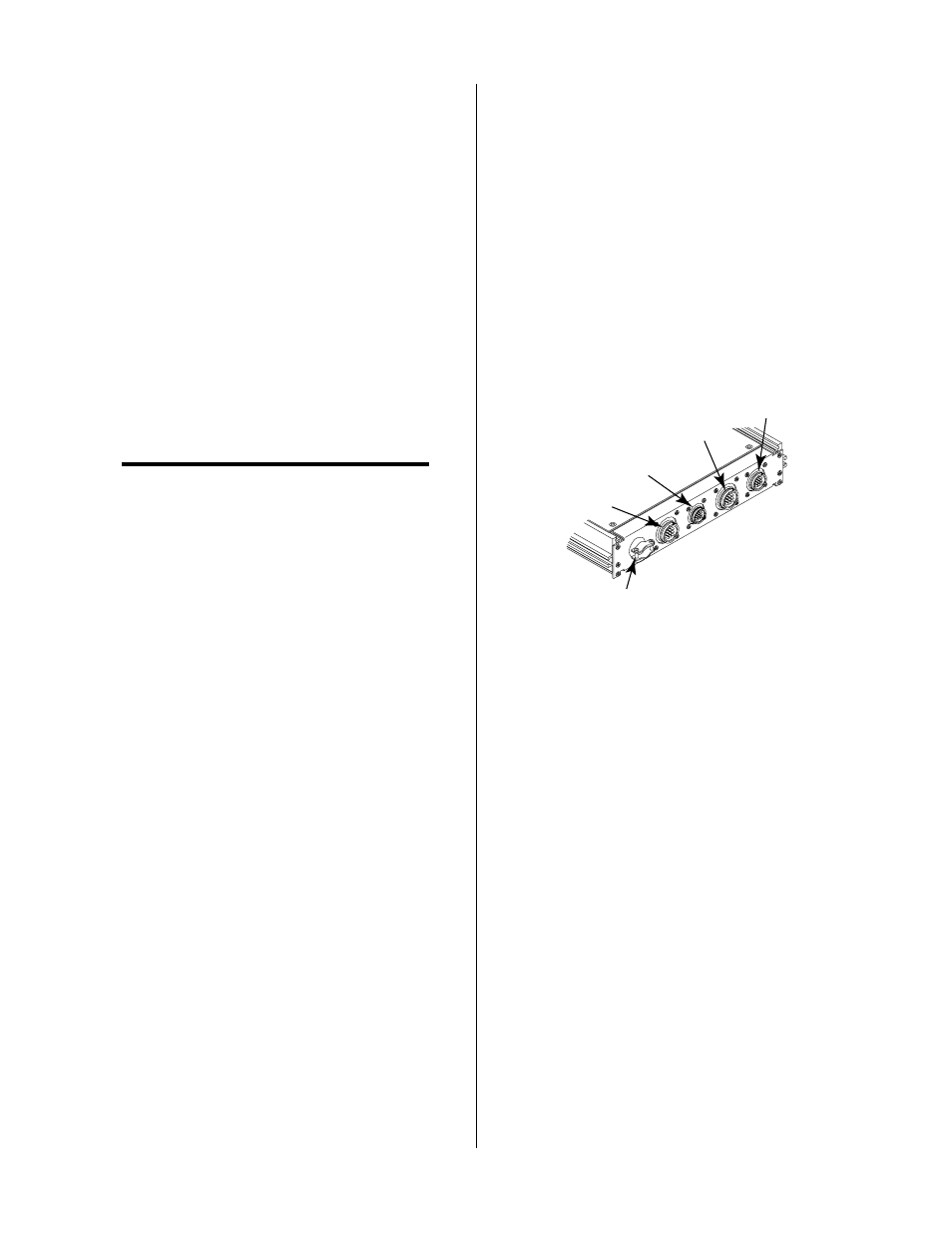

B. Rear Panel

A-01426

1

2

3

4

5

Figure 4-2 Rear Panel Connectors

1. MOTOR (J43) Connector

Connector to interface the Standoff Control to the

lifter motor assembly. Signals include drive (up to

+/-20 vdc), tachometer (0 to +/- 15 vdc) and TORCH

ON WORK switch (NC).

2. PLASMA (J42) Connector

Connector to interface the Standoff Control to the

Plasma Power Supply.

3. EXTERNAL POWER (J41) Connector

Connector to interface the Standoff Control to a re-

mote 48 vdc bias supply.

4. CNC (J40) Connector

Connector to interface the Standoff Control to the

CNC equipment when the interface cable has a mat-

ing connector.

5. Strain Relief

Connection to interface the Standoff Control to the

CNC equipment when there is no mating connector.

The CNC cable is fed through the strain relief and

connected to an internal terminal strip (J11).