Tweco SC11 User Manual

Page 20

INSTALLATION PROCEDURES

3-4

Manual 0-2556

PLA

SM

A O

N

AR

C V

OL

TS

RE

MO

TE

ST

AN

DO

FF

C

ON

TR

OL

T.H

.C. A

CTIV

E

PIE

RC

E

HT (in

che

s)

0.1

0.3

0.4

0.5

0.2

END

OF

CU

T

RETR

AC

T (%

)

0

25

75

100

UP

DN

TOR

CH

TORCH

MO

DE

MODE

LIFT

ER

LIFTER

SPE

ED

SPEED

PIE

RC

E

DEL

AY

(sec)

0.5

1

2

3

0.75

0.25

0.1

AU

TO

HT

FIN

D

HT

HI

LO

A-00689

Screw

Screw

Cover

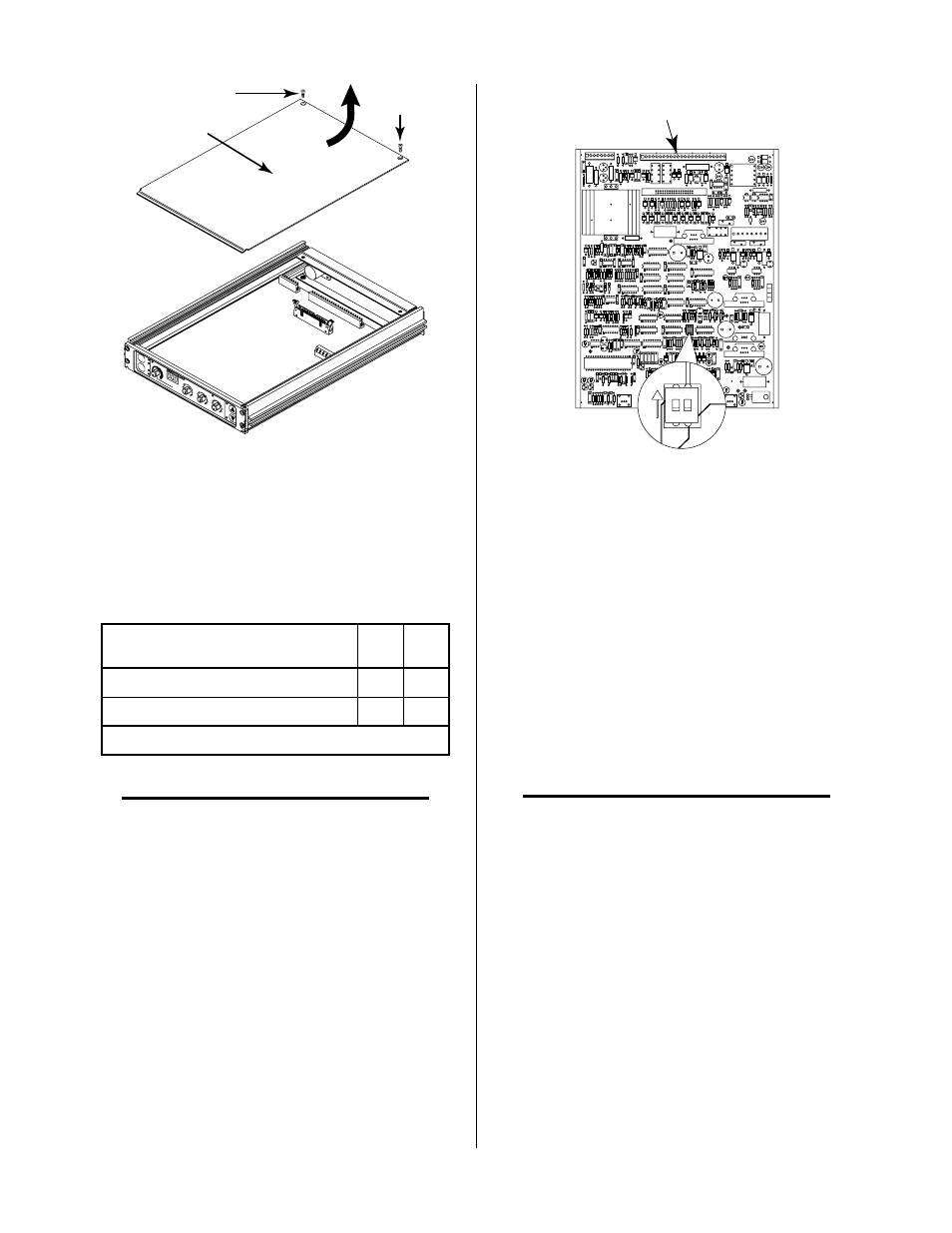

Figure 3-6 Cover Removal

2. Remove the enclosure cover by lifting straight up at

the rear of the cover and pulling it towards the rear of

the unit. The front edge of the cover fits under a lip

on the front panel assembly.

3. Identify internal switch SW1 and confirm that the

switch is set for the desired system as follows:

System

SW1-

1

SW1-

2

Without Motion Signal (OK-To-Move)

ON

ON

With Motion Signal (OK-To-Move)

OFF* OFF*

* = Factory Setting

NOTE

Refer to Section 4.04-E for operation when start-

ing the the cutting operation off the plate (work-

piece).

Standoff Control

PC Board Assembly

A-00861

SW1

Type System

Selection

2

1

ON

Figure 3-7 Switch SW1 Location

B. CNC Interface

Isolated START, standoff inhibit (CSD) and motion

(OK-To-Move) signals are available at the Rear Panel

CNC (J40) connector or an internal terminal strip (J11).

The motion signal (OK-To-Move) may be selected to

be either a contact closure or 24 VAC switched

through the contact. The Standoff Control is factory-

set for 24 VAC operation. The purpose of selecting

24 VAC is to drive a relay coil whose current must

not exceed 150 ma.

NOTE

The 24 VAC may be required by some cutting ma-

chine controllers.