Section 2: introduction & description, 01 scope of manual, 02 general description – Tweco SC11 User Manual

Page 15: 03 specifications & design features, Section 2, Introduction & description -1

Manual 0-2556

2-1

INTRODUCTION & DESCRIPTION

SECTION 2:

INTRODUCTION &

DESCRIPTION

2.01 Scope of Manual

This manual contains descriptions, operating instructions

and maintenance procedures for the SC11 Standoff Con-

trol Accessory. Service of this equipment is restricted to

properly trained personnel; unqualified personnel are

strictly cautioned against attempting repairs or adjust-

ments not covered in this manual, at the risk of voiding

the Warranty.

Read this manual thoroughly. A complete understand-

ing of the characteristics and capabilities of this equip-

ment will assure the dependable operation for which it

was designed.

2.02 General Description

The SC11 Standoff Control Accessory extends the neces-

sary system controls away from the power supply and is

an accessory for use with standard machine torch sys-

tems.

NOTE

The SC11 Standoff Control functions without con-

nection to the Remote Control Accessory RC6010.

The SC11 Standoff Control has all the connections re-

quired at the rear panel. The connections are for CNC

Control, External Power, Lifter Motor, and Plasma Power

Supply. The inputs and outputs at these connections al-

low the various parts of the system to be operated at one

station.

The Standoff Control receives bias power (+48 vdc), torch

voltage signal (0-12 vdc = 0-200 arc volts) and sends and

receives power supply and CNC control signals such as

start, arc transfer (OK-To-Move) and standoff inhibit

(CSD).

The Standoff Control operates the torch lifter motor as-

sembly to find height, regulate height and retract at end

of cut. Height is regulated by comparing the torch arc

voltage with a preset reference voltage (ARC VOLTS con-

trol) and using the resulting error voltage to raise and

lower the torch lifter motor.

A-00686

PLA

SM

A O

N

ARC VOLTS

RE

MO

TE

ST

AN

DO

FF

CO

NT

RO

L

T.H

.C. A

CTIV

E

PIER

CE

HT (i

nche

s)

0.1

0.3

0.4

0.5

0.2

END

OF C

UT

RET

RAC

T (%

)

0

25

75

100

UP

DN

TOR

CH

TORCH

MO

DE

MODE

LIFT

ER

LIFTER

SPE

ED

SPEED

PIER

CE

DEL

AY (s

ec)

0.5

1

2

3

0.75

0.25

0.1

AUTO

HT

FIND

HT

HI

LO

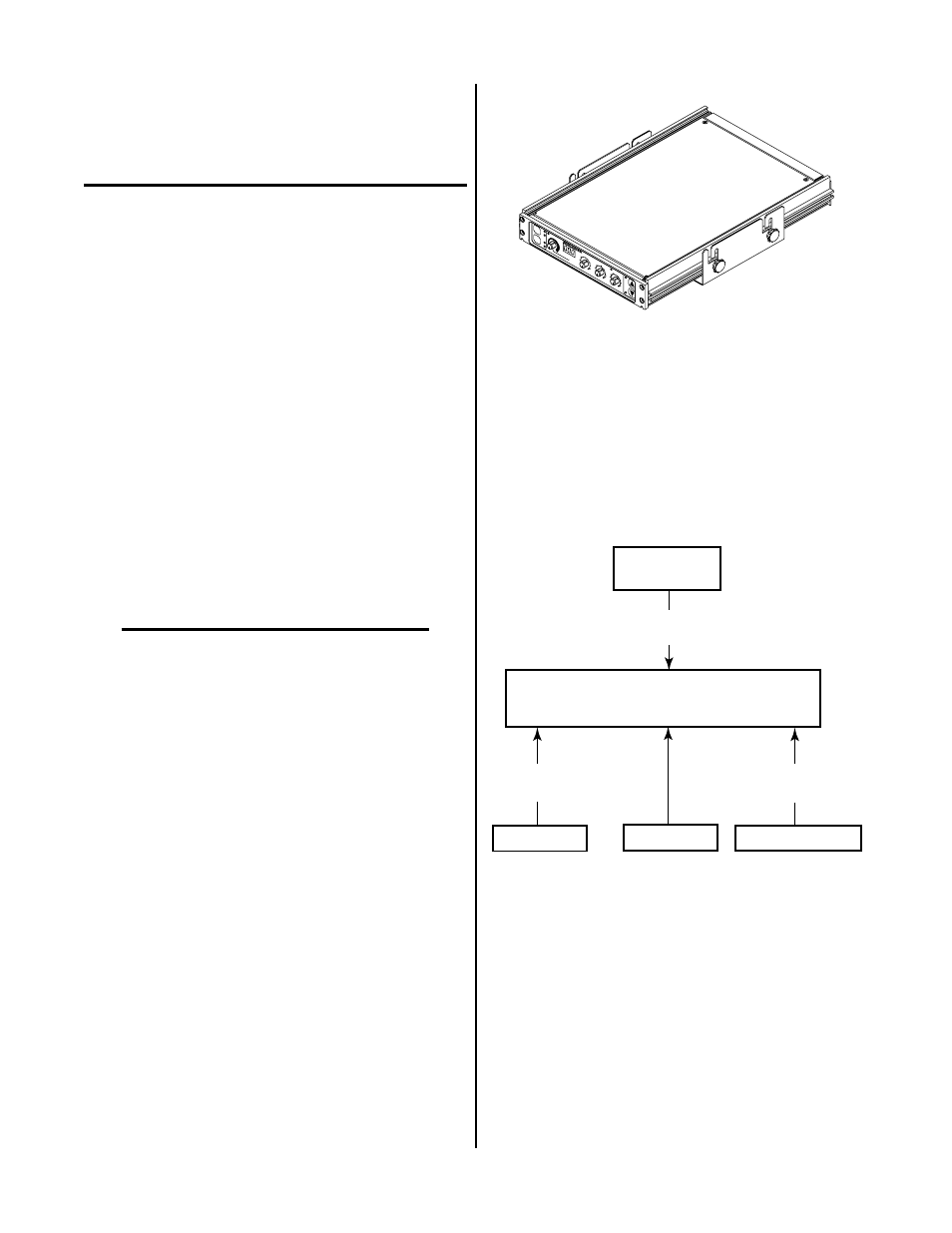

Figure 2-1 SC11 Standoff Control

All necessary cables are supplied for the type system or-

dered. If the SC11 Standoff Control Accessory is not pur-

chased as part of a system, the appropriate remote con-

trol cable and a CNC cable (if required) must be ordered

separately. Some systems may require an external 48 volt

power source. Refer to Section 6, Parts Lists, for order-

ing information.

A-00700

Standoff

Control Accessory

CNC

Lifter Motor

Lifter Motor

Control Cable

Power Supply

Control Cable

Plasma Power

Supply

CNC

Control Cable

Input Power

Figure 2-2 System Configuration With SC11

2.03 Specifications & Design

Features

A. Standoff Control

The following applies to the Standoff Control Assembly

only.

1. System Compatiblility

The Standoff Control Accessory was designed to be

used with various Plasma Cutting Systems