05 cut quality, 05 cut quality -3 – Tweco PCM-120 Machine Torch User Manual

Page 23

Manual 0-2698

4-3

OPERATION

1. Unscrew and remove the shield cup from the torch

head.

2. Using the multi-purpose wrench (5/8 inch slot) re-

move the tip.

Electrode

Shield Cup

Tip

Gas

Distributor

Torch Head

Water Tube Extension

(Gouging Only)

A-02188

Figure 4-3 Torch Parts

3. Tilt the torch head to remove the gas distributor. The

end of the multi-purpose wrench can be used to help

remove the gas distributor.

4. Using the multi-purpose wrench (electrode area) re-

move the electrode.

5. Remove gouging water extension tube, if used.

6

. Install the desired electrode for the operation into the

torch head. The circular area around the wrench used

for electrodes will also align the electrode in the torch

head. This will prevent installing the electrode on an

angle and cross threading the electrode in the torch

head.

7. Install gouging water extension tube if required.

8. Install the desired gas distributor and tip for the op-

eration into the torch head.

NOTE

Be careful not to overtighten the electrode and tip

when reinstalling.

9. Hand tighten the shield cup until it is seated on the

torch head. If resistance is felt when installing the

cup, check the threads before proceeding.

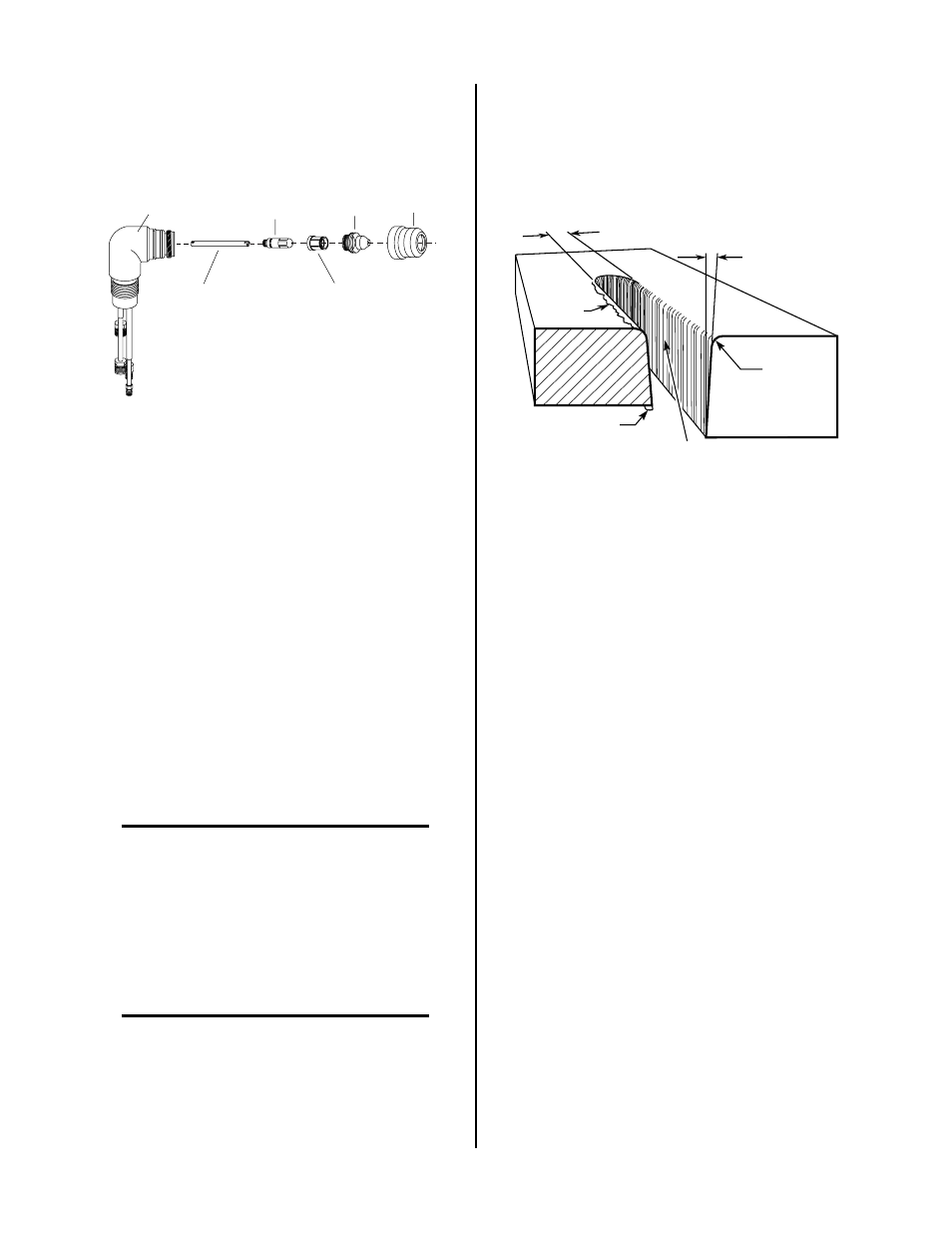

4.05 Cut Quality

NOTE

Cut quality depends heavily on set-up and param-

eters such as torch standoff, alignment with the

workpiece, cutting speed, gas pressures, and op-

erator ability.

Cut quality requirements differ depending on applica-

tion. For instance, nitride build-up and bevel angle may

be major factors when the surface will be welded after

cutting. Dross-free cutting is important when finish cut

quality is desired to avoid a secondary cleaning opera-

tion. The following cut quality characteristics are illus-

trated in the following Figure:

Kerf Width

Cut Surface

Bevel Angle

Top Edge

Rounding

Cut Surface

Drag Lines

Dross

Build-Up

Top

Spatter

A-00007

Figure 4-4 Cut Quality Characteristics

A. Cut Surface

The desired or specified condition (smooth or rough)

of the face of the cut.

B. Nitride Build-Up

Nitride deposits can be left on the surface of the cut

when nitrogen is present in the plasma gas stream.

These buildups may create difficulties if the material

is to be welded after the cutting process.

C. Bevel Angle

The angle between the surface of the cut edge and a

plane perpendicular to the surface of the plate. A per-

fectly perpendicular cut would result in a 0° bevel

angle.

D. Top-Edge Rounding

Rounding on the top edge of a cut due to wearing

from the initial contact of the plasma arc on the work-

piece.

E. Bottom Dross Build-up

Molten material which is not blown out of the cut

area and re-solidifies on the plate. Excessive dross

may require secondary clean-up operations after cut-

ting.

F. Kerf Width

The width of the cut (or the width of material re-

moved during the cut).