06 setting up machine torch, 07 gas selection – Tweco PCM-120 Machine Torch User Manual

Page 18

INSTALLATION PROCEDURES

3-2

Manual 0-2698

6. If installing a machine torch with shielded leads,

complete the following:

a. Remove one nut and star washer from the

Torch leads Shield Stud.

b. Place the ring lug on the torch leads shield wire

over the stud and secure with nut and star

washer.

7. Connect torch coolant and gas leads to connec-

tors, as indicated on bulkhead.

8. Close the access panel and turn the two latching

screws.

9. Connect the other end of the Control Cable to a

CNC device, if applicable.

A-02113

Secondary

Gas

Plasma (+)

Gas

Control Cable

Connector

Coolant

Return

Coolant

Supply (-)

CNC Control

Cable

Torch Leads

Shield Stud

Shield Wire

With Ring Lug

Figure 3-3 Torch Leads Connections

3.06 Setting Up Machine Torch

WARNING

Disconnect primary power at the source before dis-

assembling the torch or torch leads.

A Metal Mounting Tube with Rack and Pinion Assembly

is standard for machine torches. A Remote Hand Pen-

dant is included with unshielded leads; a CNC Interface

Cable is included with shielded leads.

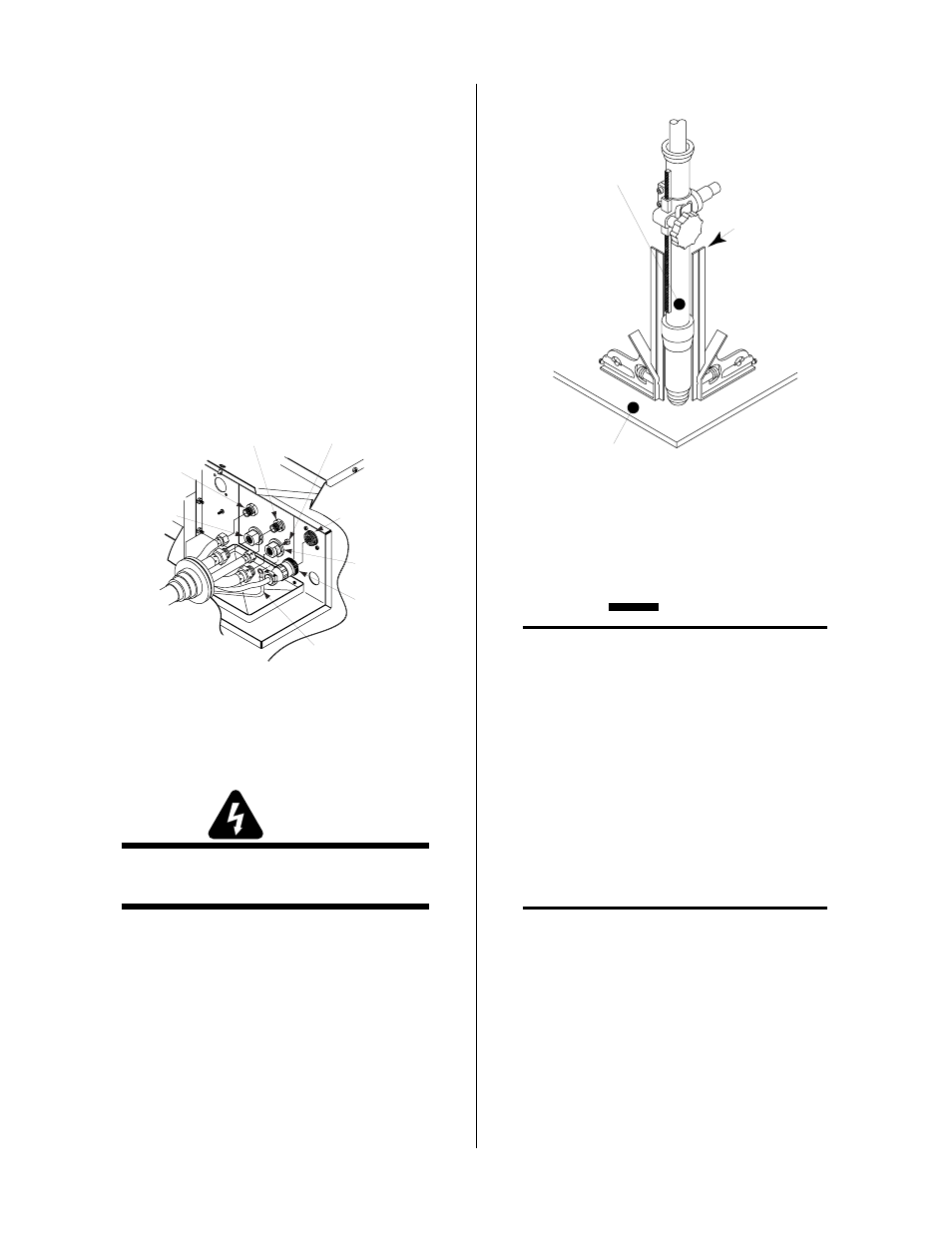

1. Mount the torch assembly on the cutting table.

2. To obtain a clean vertical cut, use a square to align

the torch perpendicular to the surface of the work-

piece.

Rack and

Pinion Mounting

Assembly

Square

A-00660

Workpiece

Figure 3-4 Machine Torch Set-Up

3.07 Gas Selection

CAUTIONS

Maximum input gas pressure must not exceed 125

psi (8.6 bar)

Air supply must be free of oil, moisture, and other

contaminants. Excessive oil and moisture may

cause double-arcing, rapid tip wear, or even com-

plete torch failure. Contaminants may cause poor

cutting performance and rapid electrode wear.

The type of operation will determine the best gases to be

used. Refer to the following and select the plasma and

secondary gases that best fit the operation(s):

A. Plasma Gases

NOTE

Refer to Section 2.03, Specifications & Design Fea-

tures, for proper gas pressure and flow rate.

1. Compressed Air Plasma

• Most often used on ferrous or carbon base materi-

als to obtain good quality at faster cutting speeds.

• Air plasma is normally used with air secondary.

• Only clean, dry air is recommended for use as

plasma gas. Any oil or moisture in the air supply

will substantially reduce torch parts life.

• Provides satisfactory results on non-ferrous mate-

rials.