Tweco 6000 Cutting Systems User Manual

Page 49

Man

ual 0-2689

A-3

APPENDIX

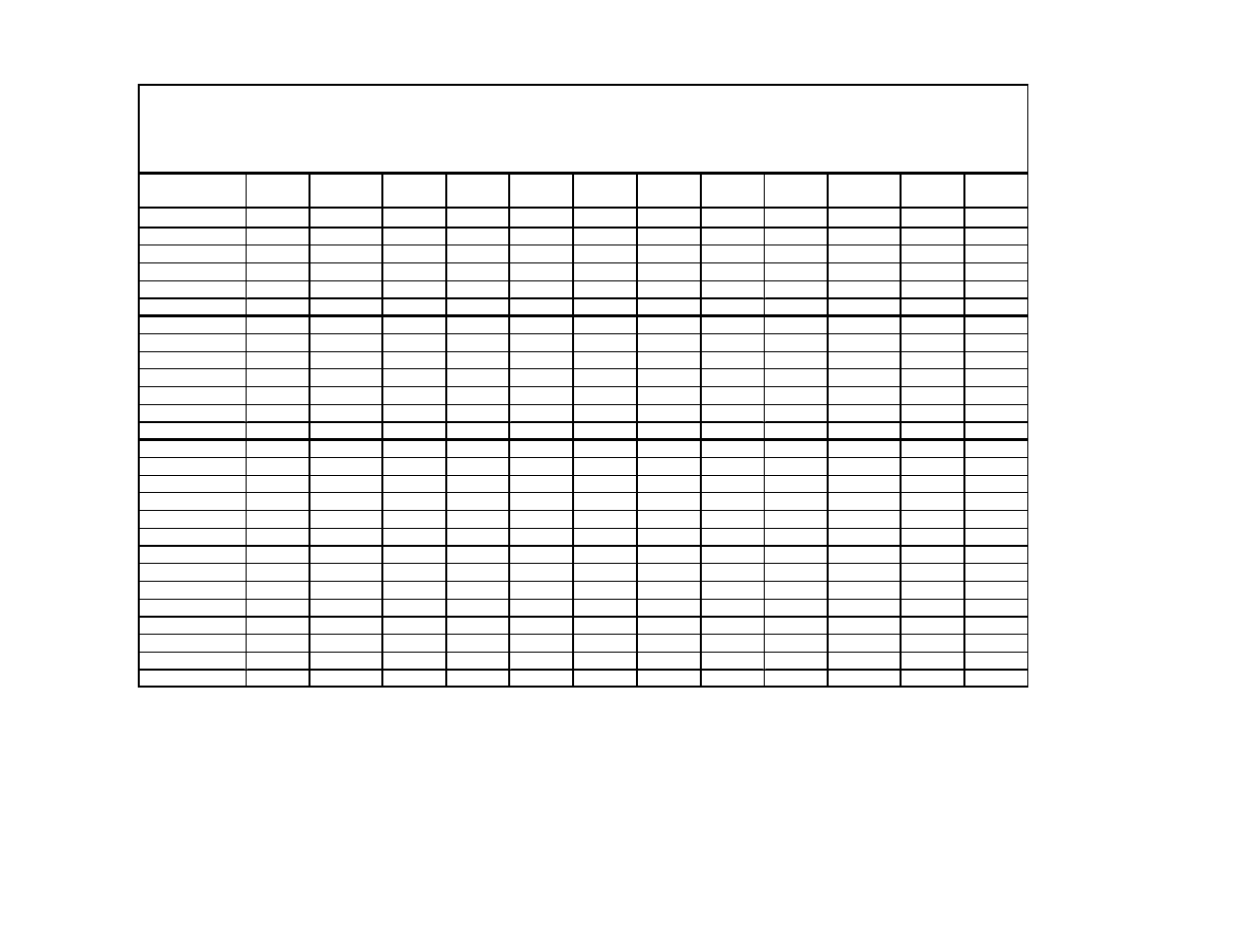

NOTES

1. Recommended plasma pressure setting for 60 ft (18.3 m) total hose length (extension plus leads). For every 10 ft (3 m) of additional

hose length add 2.5 psi (0.17 bar) to the plasma pressure setting.

2. Recommended secondary pressure setting for 60 ft (18.3 m) total hose length (extension plus leads). For every 10 ft (3 m) of addi-

tional hose length add 1.0 psi (0.07 bar) to the secondary pressure setting.

3. Piercing materials 3/4 inch (19.1 mm) and over may shorten torch consumable parts life.

Metric Measurements

Air Plasma Cutting Data Chart

Maximizer 300 Torch

Aluminum

Air Plasma / Air Secondary

Electrode

Gas

Distributor

Tip

End Cap

Amperage

Output

Volts

Speed

Standoff

Plasma

Pressure

Secondary

Pressure

Pierce

Delay

Pierce

Height

Cat. No.

Cat. No.

Cat. No.

Cat. No.

amps

vdc

m / min

mm

bar

bar

seconds

mm

20-1018

20-0008

20-1030

20-1003

50

145

20.32

3.18

4.14

2.76

0.00

3.18

20-1018

20-0008

20-1030

20-1003

50

150

7.62

4.78

4.14

2.76

0.00

6.35

20-1018

20-0008

20-1030

20-1003

50

160

2.54

4.78

4.14

2.76

0.00

6.35

20-1018

20-0008

20-1030

20-1003

50

165

1.52

4.78

4.14

2.76

0.00

6.35

20-1018

20-0008

20-1030

20-1003

50

175

0.76

4.78

4.14

2.76

0.25

6.35

20-1018

20-0008

20-1031

20-1004

100

140

10.16

4.78

4.83

1.38

0.10

5.08

20-1018

20-0008

20-1031

20-1004

100

140

5.08

4.78

4.83

1.38

0.10

5.08

20-1018

20-0008

20-1031

20-1004

100

145

3.05

4.78

4.83

1.38

0.10

5.08

20-1018

20-0008

20-1031

20-1004

100

150

2.54

4.78

4.83

1.38

0.20

6.35

20-1018

20-0008

20-1031

20-1004

100

155

1.91

4.78

4.83

1.38

0.20

6.35

20-1018

20-0008

20-1031

20-1004

100

160

1.27

4.78

4.83

1.38

0.30

6.35

20-1018

20-0008

20-1031

20-1004

100

170

0.76

4.78

4.83

1.38

0.50

9.53

20-1018

20-0008

20-1032

20-1004

150

155

3.81

6.35

4.83

1.38

0.00

9.53

20-1018

20-0008

20-1032

20-1004

150

160

2.54

6.35

4.83

1.38

0.00

9.53

20-1018

20-0008

20-1032

20-1004

150

160

2.03

6.35

4.83

1.38

0.25

9.53

20-1018

20-0008

20-1032

20-1004

150

160

1.52

6.35

4.83

1.38

0.25

9.53

20-1018

20-0008

20-1032

20-1004

150

175

1.14

7.92

4.83

1.38

0.38

11.10

20-1018

20-0008

20-1032

20-1004

150

185

0.64

7.92

4.83

1.38

0.50

12.70

20-1018

20-0008

20-1033

20-1004

225

150

3.18

6.35

4.83

1.38

0.00

9.53

20-1018

20-0008

20-1033

20-1004

225

160

2.03

6.35

4.83

1.38

0.25

9.53

20-1018

20-0008

20-1033

20-1004

225

165

1.52

6.35

4.83

1.38

0.25

12.70

20-1018

20-0008

20-1033

20-1004

225

170

0.76

7.92

4.83

1.38

0.50

12.70

20-1021

20-1009

20-1034

20-1005

300

155

1.91

6.35

4.83

1.38

0.50

12.70

20-1021

20-1009

20-1034

20-1005

300

160

1.52

6.35

4.83

1.38

0.75

12.70

20-1021

20-1009

20-1034

20-1005

300

170

0.56

6.35

4.83

1.38

NR

NR

20-1021

20-1009

20-1034

20-1005

300

190

0.41

6.35

4.83

1.38

NR

NR

38.1

25.4

50.8

0.9

1.6

3.2

4.8

6.4

15.9

15.9

19.1

12.7

19.1

25.4

15.9

6.4

9.5

25.4

12.7

19.1

4.8

6.4

9.5

12.7

Material

Thickness

mm

1.6

3.2