Tweco 6000GST Cutting Systems User Manual

Page 58

APPENDIX

A-12

Man

ual 0-2690

APPENDIX 2:

CUTTING SPEED CHAR

TS FOR

MERLIN 6000GST SYSTEMS (contin

ued)

NOTE

If the Optional Secondary Gas/Water Flow Control is used on the Gas Control Module, then the Gas HIGH-FLOW/LOW-FLOW

switch must be in the HIGH-FLOW position.

US Measurements

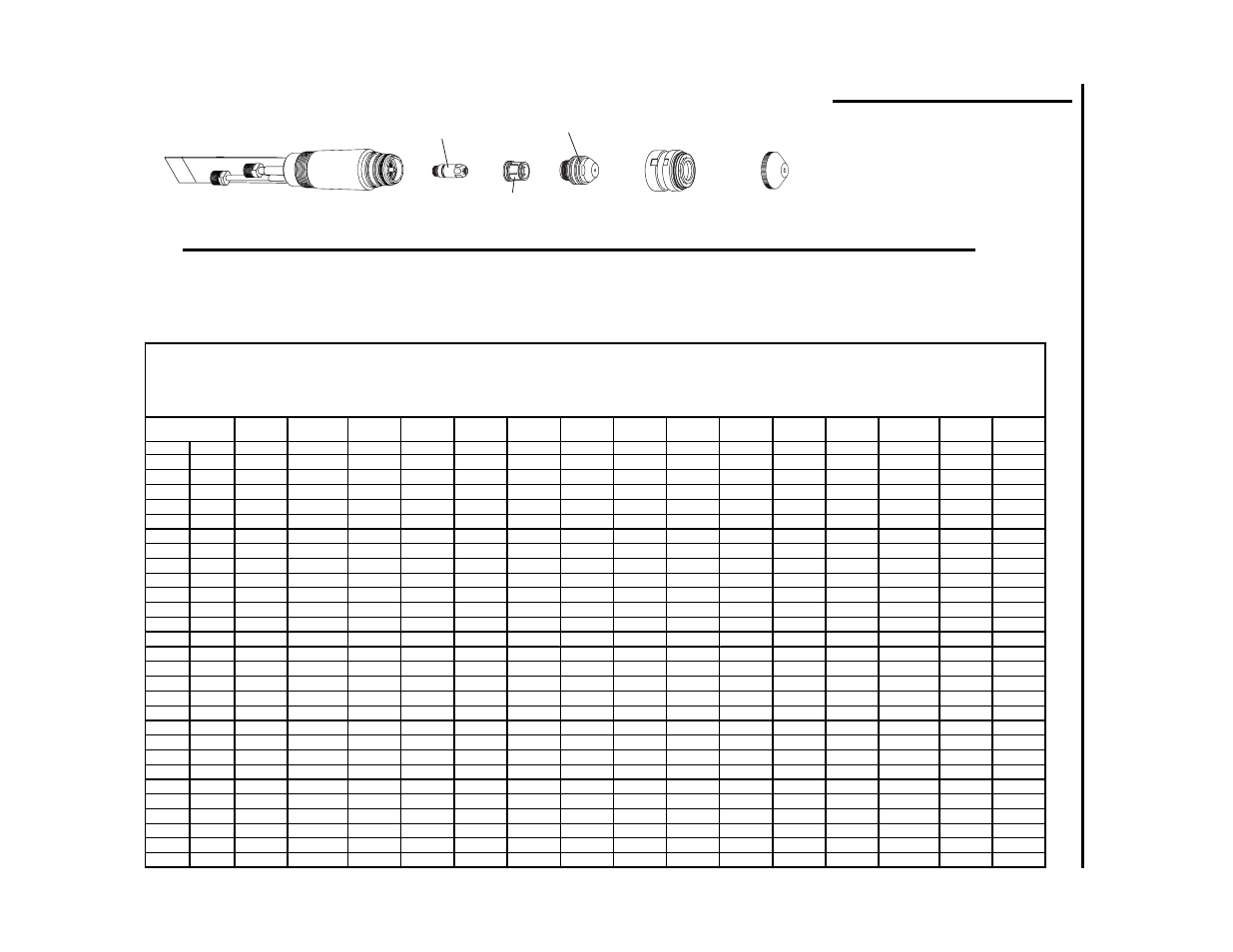

Oxygen Plasma Cutting Data Chart

Maximizer 300 Torch

Mild Steel

Oxygen Plasma / Air Secondary

Electrode

Gas

Distributor

Tip

End Cap

Amperage

Output

Volts

Speed

Standoff

Preflow

Pressure

Preflow

Flowball

Plasma

Pressure

Plasma

Flowball

Secondary

Pressure

Pierce

Delay

Pierce

Height

inches

Gauge

Cat. No.

Cat. No.

Cat. No.

Cat. No.

amps

vdc

inches/min

inches

psi

psi

psi

seconds

inches

0.035

20

20-1018

20-0008

20-1030

20-1003

50

125

800

0.125

90

52

75

72

22

0.00

0.125

1/16

16

20-1018

20-0008

20-1030

20-1003

50

130

350

0.188

90

52

75

72

22

0.20

0.250

1/8

10

20-1018

20-0008

20-1030

20-1003

50

135

160

0.188

90

52

75

72

22

0.50

0.250

3/16

7

20-1018

20-0008

20-1030

20-1003

50

140

105

0.188

90

52

75

72

22

0.50

0.250

1/4

20-1018

20-0008

20-1030

20-1003

50

140

75

0.188

90

52

75

72

22

0.75

0.250

1/16

16

20-1018

20-0008

20-1031

20-1004

100

125

500

0.125

90

76

100

92

35

0.00

0.250

1/8

10

20-1018

20-0008

20-1031

20-1004

100

125

250

0.250

90

76

100

92

35

0.00

0.250

3/16

7

20-1018

20-0008

20-1031

20-1004

100

125

190

0.250

90

76

100

92

35

0.00

0.250

1/4

20-1018

20-0008

20-1031

20-1004

100

125

115

0.250

90

76

100

92

35

0.00

0.250

3/8

20-1018

20-0008

20-1031

20-1004

100

130

65

0.250

90

76

100

92

35

0.25

0.375

1/2

20-1018

20-0008

20-1031

20-1004

100

132

55

0.250

90

76

100

92

35

0.50

0.500

5/8

20-1018

20-0008

20-1031

20-1004

100

132

45

0.250

90

76

100

92

35

0.50

0.500

1/4

20-1010

20-0008

20-1032

20-1004

150

125

175

0.188

90

76

100

92

35

0.00

0.250

3/8

20-1010

20-0008

20-1032

20-1004

150

125

110

0.188

90

76

100

92

35

0.25

0.375

1/2

20-1010

20-0008

20-1032

20-1004

150

130

65

0.250

90

76

100

92

35

0.25

0.375

5/8

20-1010

20-0008

20-1032

20-1004

150

130

40

0.250

90

76

100

92

35

0.25

0.375

3/4

20-1010

20-0008

20-1032

20-1004

150

130

30

0.250

90

76

100

92

35

0.50

0.500

1

20-1010

20-0008

20-1032

20-1004

150

130

25

0.250

90

76

100

92

35

0.50

0.500

1/2

20-1010

20-0008

20-1033

20-1004

225

120

125

0.250

105

69

90

90

35

0.50

0.375

5/8

20-1010

20-0008

20-1033

20-1004

225

125

75

0.250

105

69

90

90

35

0.50

0.500

3/4

20-1010

20-0008

20-1033

20-1004

225

125

53

0.250

105

69

90

90

35

0.75

0.500

1

20-1010

20-0008

20-1033

20-1004

225

128

45

0.250

105

69

90

90

35

0.75

0.500

3/4

20-1021

20-1009

20-1034

20-1005

300

130

70

0.250

105

86

90

120

30

0.50

0.500

1

20-1021

20-1009

20-1034

20-1005

300

135

50

0.250

105

86

90

120

30

0.50

0.500

1 1/4

20-1021

20-1009

20-1034

20-1005

300

135

38

0.250

105

86

90

120

30

NR

NR

1 1/2

20-1021

20-1009

20-1034

20-1005

300

140

25

0.250

105

86

90

120

30

NR

NR

1 3/4

20-1021

20-1009

20-1034

20-1005

300

150

16

0.312

105

86

90

120

30

NR

NR

2

20-1021

20-1009

20-1034

20-1005

300

155

10

0.312

105

86

90

120

30

NR

NR

Material

Thickness

Art # A-02186

Shield Cup Body

20-1002*

End Cap

(See Chart)

Tip

(See Chart)

Gas Distributor

(See Chart)

Electrode

(See Chart)

*or Ohmic Clip

Shield Cup Body 20-1427

Torch Body

180˚: 9-6410

70˚: 9-6457 90˚: 9-6459

NOTE:

If using a torch height control which

offers an ohmic sensing feature, select a

shield cup body with an ohmic clip tab.

Use catalog # 20-1427 for normal cut-

ting and catalog 20-1428 for cutting

underwater.