Triton TCB 100 User Manual

Page 8

8

GB

Assembly

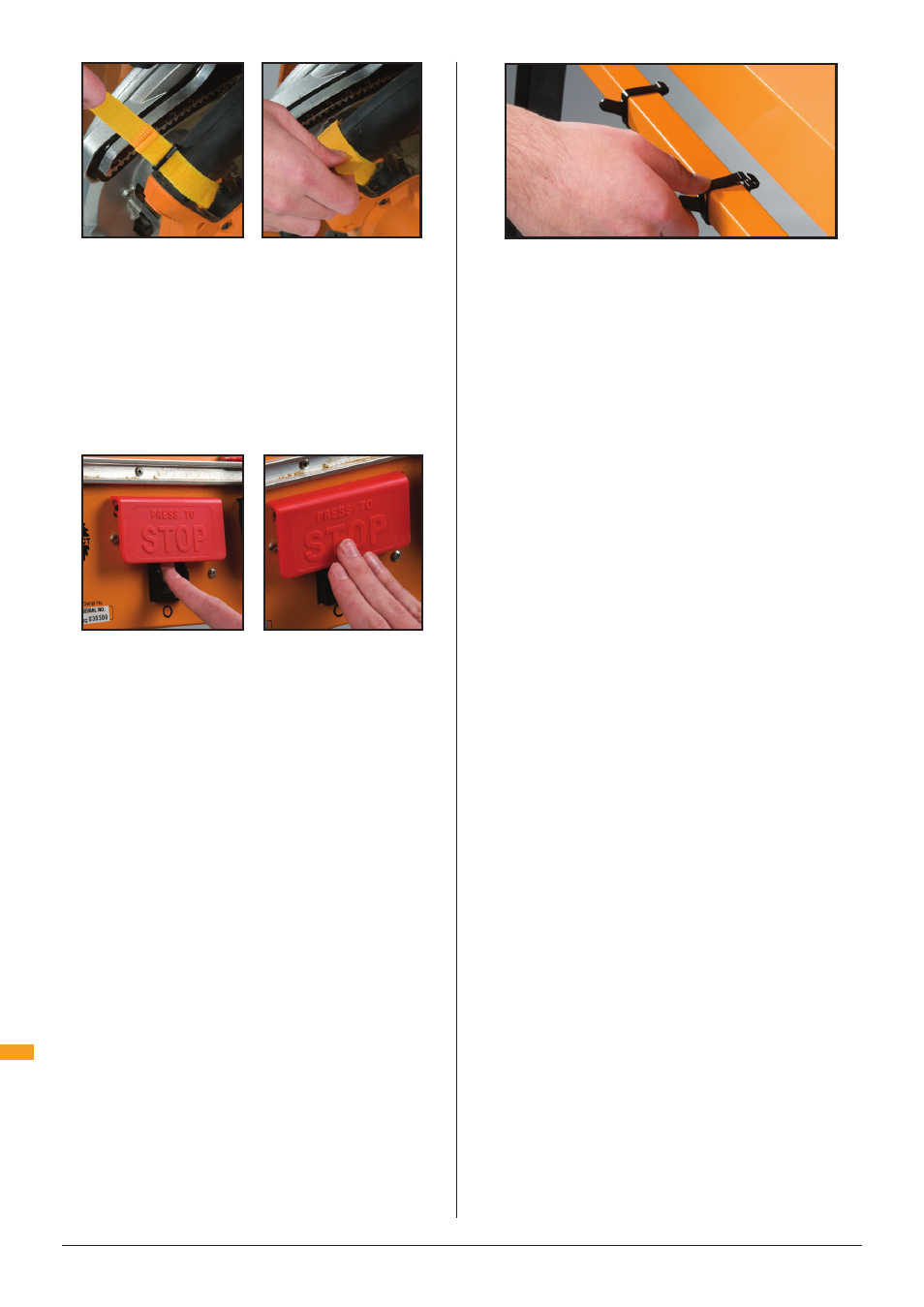

With most saws, the strap can be slid on and off the

saw trigger without having to be undone each time.

CONNECTING THE POWER

Before connecting the power, practice switching on

and off. Do not raise the Stop plate.

Press the green switch with your finger to switch the

power ON. Tap the stop plate with your hand or thigh

to switch OFF (Fig 15).

Make sure the switch is OFF, plug the saw into the

switch box inside the front panel and bring power to

the switch box via an extension cable (min 10 Amp).

Before switching on the power, make sure that nothing

is touching the saw blade, or is likely to vibrate into it,

and that your hands are well clear of the blade.

Switch on and off a few times, with the safety guard

raised approx 25mm above the table, and check that

your saw blade is running true. Any buckle or twist in

the blade will be most evident as the blade is slowing

down to stop. If the blade quivers badly on slow-down,

check whether it is properly seated on the saw arbour.

If it is, for best results you may need to replace your

blade.

FITTING THE STORAGE HOOKS

The Storage Hooks (17) enable temporary storage

of table accessories when not in use. Fit them onto

the left or right hand base tube by opening them and

clipping them around the tube (Fig 16).

THE RIP FENCE

The rip fence can be fitted to the left or right hand

side of the unit, depending on which you find most

comfortable or to suit certain cuts or jigs.

CALIBRATION SETTINGS

The pointer notch is 2.5mm wide, and represents the

kerf (width of cut) of most tungsten carbide tipped

blades. Provided your blade does remove 2.5mm of

material, the scales will be highly accurate with the

fence on either side of the blade.

Always sight down directly from above the notch to

avoid sighting errors.

LOCKING LEVER TENSION

If locking is too firm or too loose, you can vary the

tension of the fence locking levers.

Adjust the Nyloc self-locking nut on the inside of each

end panel.

OUTBOARD SUPPORT

By removing the fence from its tracks and replacing

it upside down, it can be used to provide effective

outboard support when crosscutting larger workpieces

against the protractor.

Secure a batten over the fence arms to create a

surface level with the table. The batten should be

14mm thick, or rebated to 14mm thick.

THE PROTRACTOR

With the sandpaper face forward, away from you,

guide the protractor strip into the slot at the front

panel. Slide the protractor fully along the slot to check

that it slides freely.

The Protractor (6) can be used in trailing mode

(protractor behind the workpiece, Fig 17), or leading

mode (protractor in front of the workpiece, Fig 18).

Trailing mode offers 250mm crosscut capacity,

leading mode 450mm. Use of trailing mode is

recommended unless you require the greater crosscut

capacity.

Fig 15

Fig 14

Fig 15

Fig 16