Triton TCB 100 User Manual

Page 6

6

GB

obstructions on the saw, such as raised sections of

the base plate or the saw’s height adjustment lever.

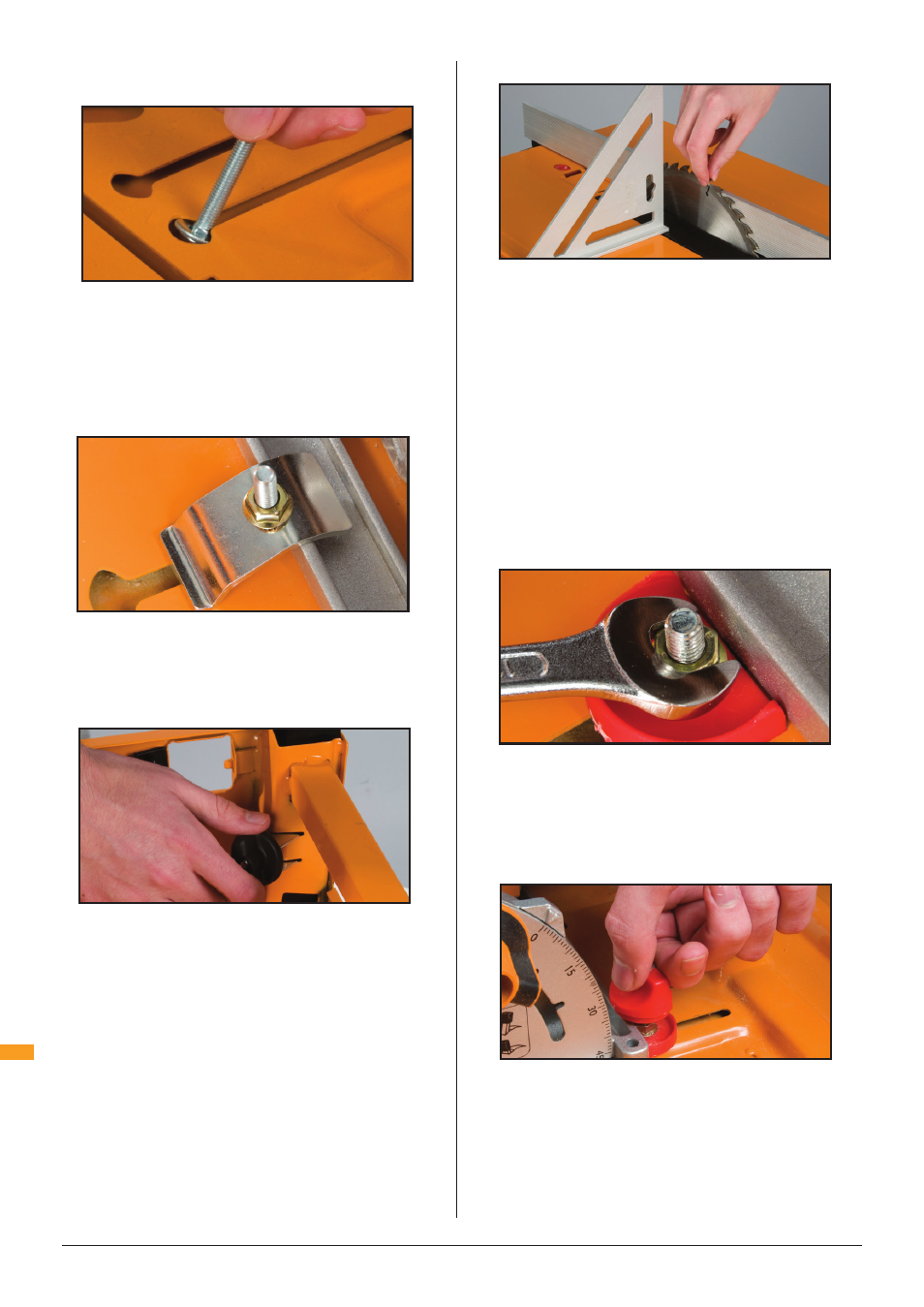

Remove the saw and fit the four long Coach Bolts (I),

with Washers (J) under their heads as shown (Fig 4),

into the selected slots.

Replace the saw, with the blade touching the fence.

Firmly finger-tighten the Temporary Saw Clamps (R)

onto the coach bolts using the Flange Nuts (K). See

Fig 5, below.

FITTING THE LEGS

Plug the Rear Legs (B) fully into their housings at the

rear of the unit. Plug the uncapped ends of the Front

Legs (C) in the front panel sockets. Lock them by

tightening the round knobs (Fig 6).

NOTE: There may be cracking noises as the powder

coat seal breaks – this is normal.

Turn the saw table right way up and test that all four

feet are square on the ground. Adjust as necessary by

extending one of the legs slightly from its housing until

unit is stable.

FINAL SAW FITTING

Use your set square to check the blade is exactly 90°

to the table. If necessary, adjust the blade angle (see

Troubleshooting).

Adjust the position of the saw so that the teeth just

touch, front and rear. This step is critical – take your

time to get it right!

Spin the blade backwards by hand. The teeth should

very lightly skim the fence set at ‘0’. Use a spanner to

tighten the flange nuts, temporarily locking the saw

in position.

Turn the unit upside down again, taking care not to

bump the saw.

Twist or snip the Clam Knobs (M) and Clamp bases

(N) from their moulding tree and trim off any remnants

with scissors or a file.

One at a time, replace the temporary saw clamps with

the plastic clamp bases. Slide them along the slots

until they touch the saw base plate and tighten the

flange nuts with a 10mm spanner (Fig 8).

The clamp bases accurately align your saw, so after

you’ve fitted them check that you cannot twist or move

the saw sideways at all.

Screw the clamp knobs onto the coach bolts (they cut

their own threads) until they touch the lip of the saw

base plate and clamp it firmly in position (Fig 9).

NOTE:

1. File any burrs in the base plate at the clamp locations

to avoid damaging the knobs

2. There is no need to over-tighten knobs. They will still

clamp securely, and be vibration-proof, if you leave

them about half a turn past where they first scrape on

the bas plate

Assembly

Fig 5

Fig 6

Fig 7

Fig 8

Fig 9

Fig 4