Triton TCB 100 User Manual

Page 10

10

GB

THE OVERHEAD GUARD

The overhead guard has hold-down fingers to prevent

kick-back. Always ensure the guard is lowered until

the fingers flex a little and lightly press the workpiece

down on the table.

Having the guard as low as possible will also improve

the dust collection by the overhead guard if a vacuum

is connected.

The bolt and knob on the overhead guard can be

reversed, if necessary, to allow the rip fence to be

adjusted closed to the blade when using the fence on

the left-hand side of the blade.

Check your square

First, check your square! Use a board with an

absolutely straight edge. Press the handle (base) of the

square firmly against it, and use a sharp pencil or utility

knife to trace the edge of the blade on the board.

Flip the square over, press it against the straight edge

again, and move the blade to the line. Any error in your

square is seen as doubled, and is thus more clearly

visible.

Crosscutting with the protractor

Set up as shown in (Fig 24), with the safety guard just

high enough to admit the piece of wood. Check that the

protractor is set at exactly ‘0’.

Switch on the power. Hold the wood firmly against the

main fence of the protractor and push down lightly with

your other hand as you feed the wood smoothly into

the blade.

Push the protractor until the workpiece is past the back

of the blade, then switch off the power by bumping the

STOP plate with your thigh.

If the leading edge of the wood fouled the overhead

guard support, or if the back of the blade re-cut or

burnished the cut end, your saw is mounted slightly

crooked. Adjust the positions of the saw clamp bases

and knobs (see ‘Final Saw Fitting’), then check the saw

alignment (see ‘Checking Saw Alignment’).

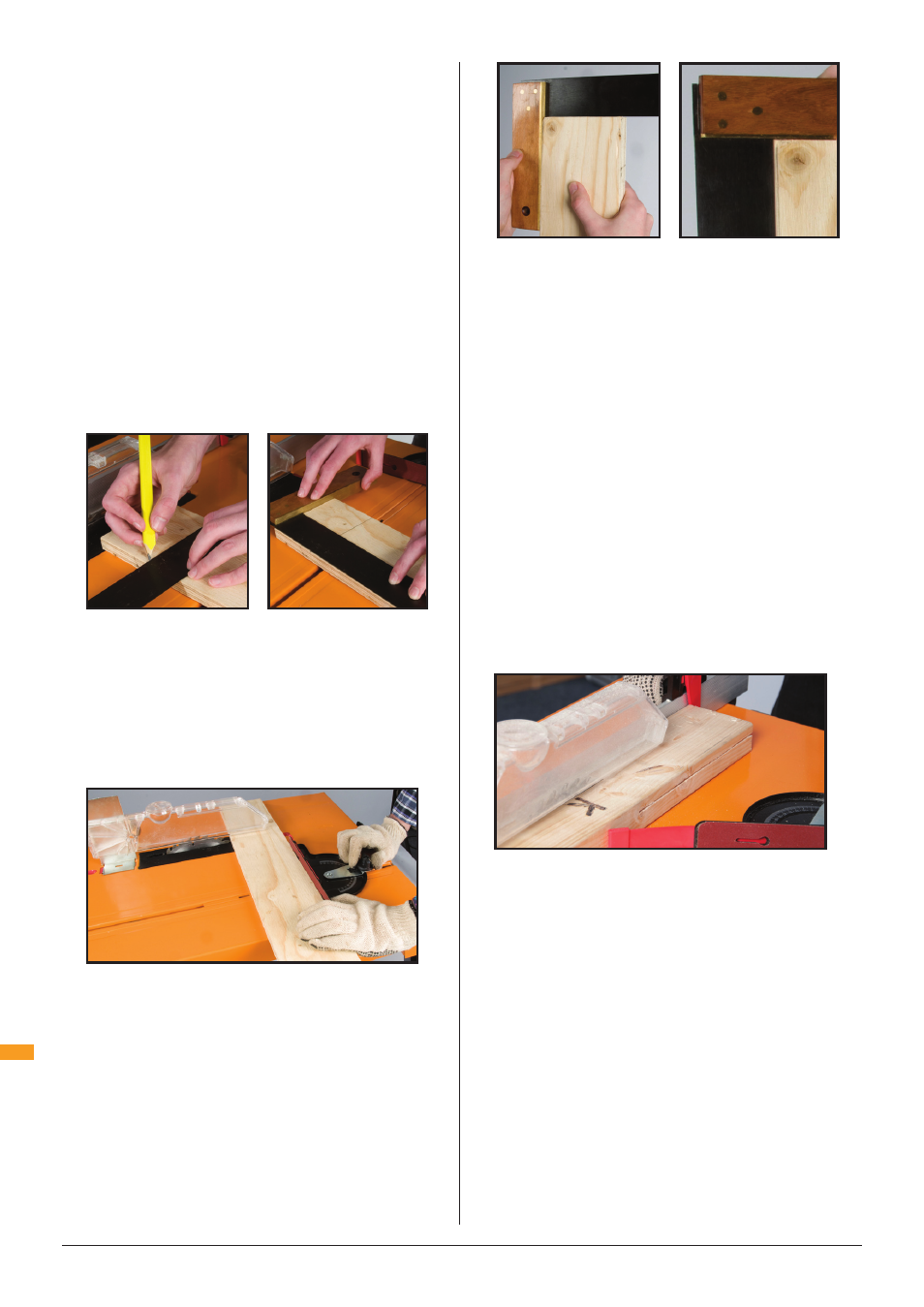

Hold the base of your square against the edge of the

timber that was against the protractor face (Fig 25a);

adjust the protractor angle slightly if necessary.

Then hold your square against the face which was on

the table (Fig 25b). Adjust the angle of the saw blade

to the table if necessary, using the saw’s adjuster. See

Troubleshooting if unable to get a satisfactory result.

Ripping test

Take a straight piece of wood at least 70mm wide and

approx 35mm thick. Place it flat on the table and lower

the overhead guard to just above the workpiece.

Lock the rip fence exactly parallel to the blade with a

fence setting that will give you an off-cut of, say, 5mm:

eg 70mm wide wood, less 3mm for the saw cut, less

5mm for the off-cut = 62mm.

Set up the captive push-stick and side pressure finger.

Switch on the power, and feed the wood smoothly.

Keep pushing it – ideally without pausing – until it is

fully past the blade. Keep fingers well away from the

blade. [Fig 26]

Hold the base of the square against the face that was

on the saw table and check the cut at various points.

Move the fence 1mm closer to the blade, front and rear,

and make a finishing cut for best results.

If the leading edge of the wood fouled the overhead

guard support, or if the back of the blade re-cut or

burnished the cut end, your saw

is mounted slightly

crooked. Adjust the positions of the saw clamp

bases and knobs (see ‘Final Saw Fitting’), then

check the saw alignment (see ‘Checking Saw

Alignment’).

Basic Ripping

Set the fence parallel to the blade, firmly locked

at both ends, with safety guard correctly lowered.

Ideally have the wider section of the workpiece

between the blade and the fence (Fig 27), so you

can keep good control of it with your hands or

with the captive push-stick.

Fig 24

Fig 26

Assembly

Fig 23

Fig 25