Assembly – Triton TCB 100 User Manual

Page 5

5

GB

UNPACKING

• Carefully unpack and check that all items are included

and in good condition

• If any items are missing or damaged, do not use this

tool. Return it to your retailer

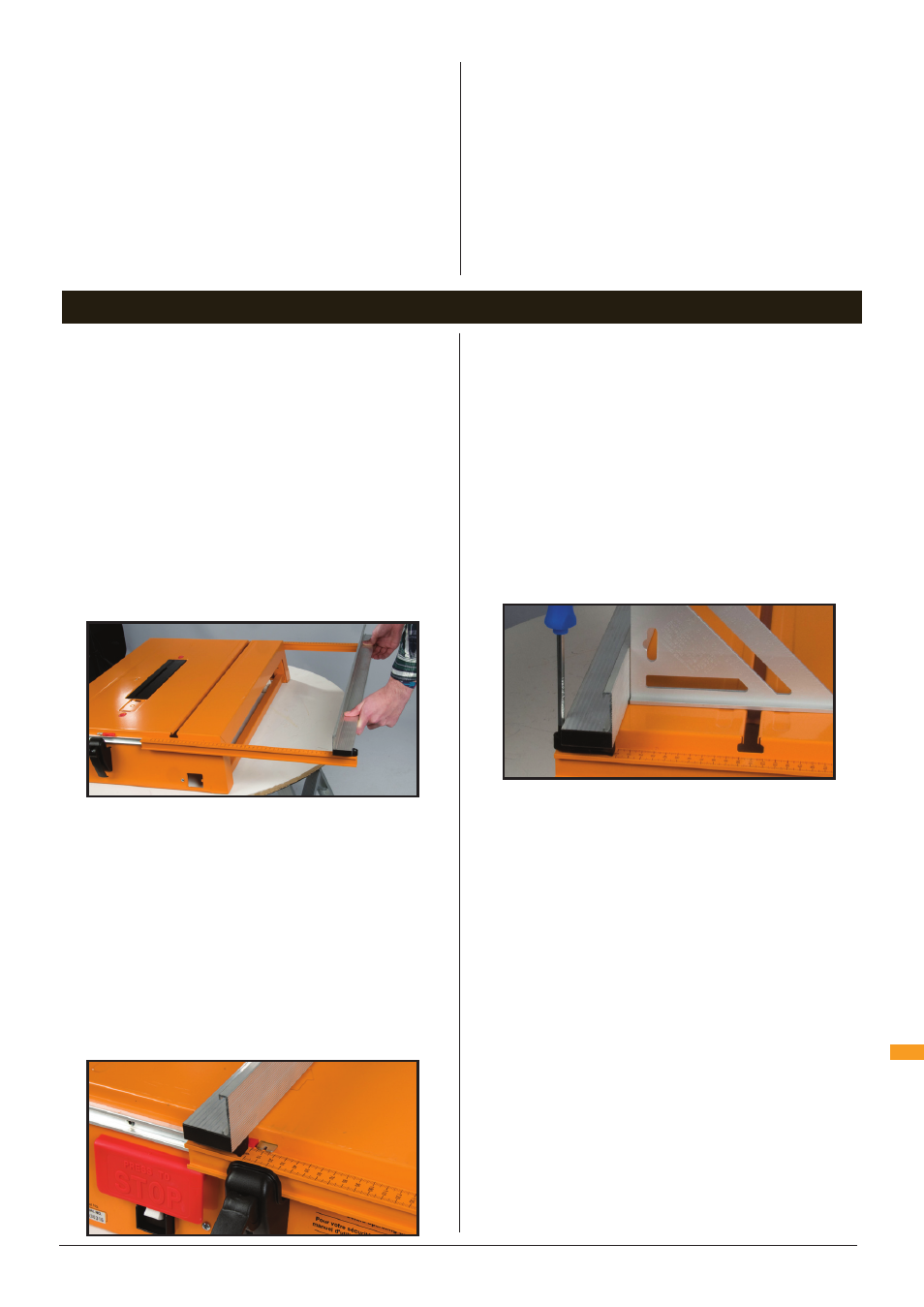

FITTING THE RIP FENCE

Fully raise the Fence Clamp Handles on the end

panels. Unfold the arms of the Rip Fence (D) and slide

it along the fence tracks from the right hand side of

the unit (when viewed from the front panel, which has

the switchbox). Note that the taller part of the fence is

facing the plastic insert in the tabletop (Fig 1).

Study the Fence Scale Pointers. The rip fence can

be fitted on the right or left hand side of the blade,

depending on the cut you are making or your personal

preference.

The 2.5mm calibration notch means that the scales

will be accurate on either side of the blade, provided

your saw has a standard width of cut (kerf) of 2.5mm

Use either side of the notch, depending on which side

your fence is set, to line up with the calibration scales

on the Fence Arms.

NOTE: If your saw has a very thin slitting blade, read

‘Using Thin Blades’ in ‘Troubleshooting’.

With the fence on the right-hand side, align the side

of the notch closest to the fence with the ‘0’ on the

scales (Fig 2). Depress the black plastic fence locking

levers at the front and rear panels to lock the fence in

that position.

Use an accurate set square to check the vertical face

of the rip fence is exactly square to the table at both

ends. If necessary, you can tilt the fence using the

jacking screws (Fig 3).

If you are making any significant adjustments, you will

need to slide the fence clear of the table and loosen or

tighten the pivot bolts attaching the fence arms. The

arms must pivot firmly but freely, without wobbling.

TEMPORARY SAW FITTING

Turn the Main Body (A) upside down and rest it on a

table or bench, with the fence overhanging the edge.

Alternatively, place the unit on wooden packers thick

enough to allow your saw blade, at maximum depth of

cut, to fit through the slot in the table.

With your saw disconnected from power, lock the

blade at full depth of cut and check that the blade is

set at 0° on the saw’s angle adjuster.

Pull back the saw’s safety guard and, with the front of

the saw facing the switch box, lower the blade through

the slot.

NOTE: The slot is sized for a 235mm (9 ¼”) blade. If

you have a smaller saw, slide it backwards until the

back of the blade is approx 10mm from the rear end

of the slot. If your blade does not fit the slot, refer to

‘Troubleshooting – Saw Fitting Problems’.

Choose the four keyhole slots which provide the

best clamping positions for your saw. If you have a

choice of slots, select those that are as far apart as

possible lengthways along the base plate. Try to avoid

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

General Safety Instructions / Assembly

Fig 1

ASSEMBLY

Fig 2

Fig 3