Triton TCB 100 User Manual

Page 11

11

GB

Assembly

Avoid trapping narrow off-cuts between the blade and

the fence, and do not stand directly in line with the

blade in case an offcut shoots out towards you.

If the wood binds slightly between the overhead guard

support and the fence, you can increase the rear fence

setting slightly, say 0.5 to 1mm.

Narrow Ripping

If you want to rip a board into a number of identical

narrow strips, or if you want to set the fence closer

than 17mm to the blade, the safety guard will prevent

access for the fence and the captive push-stick.

To resolve this, make a notched pusher, say 70mm

wide, and use it with the side pressure finger (Fig 28).

This will enable the guard to be correctly lowered,

while creating access for the push-stick.

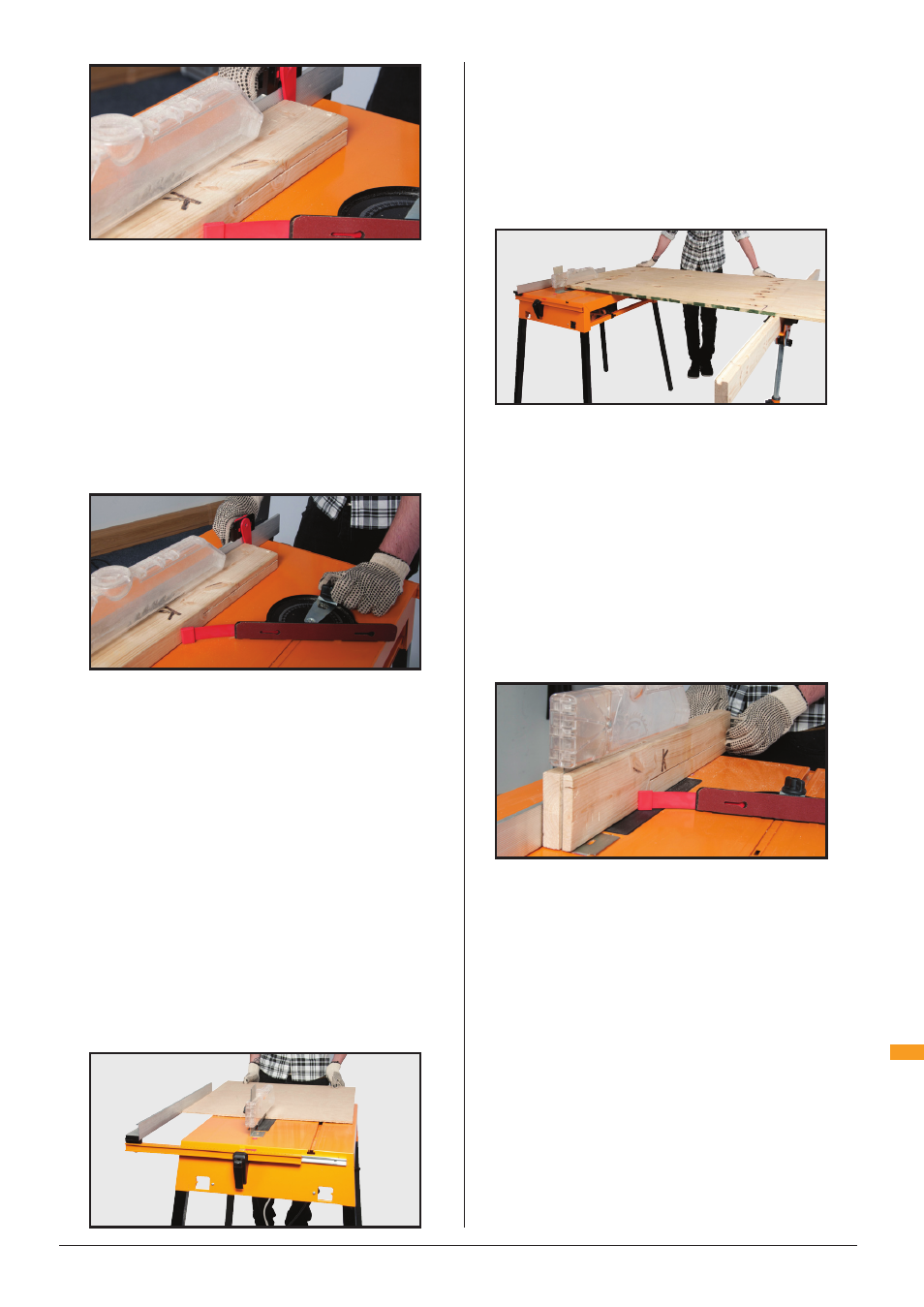

Ripping Long Pieces

When ripping long pieces which will overhang the rear

of the table by more than half their length, either have a

friend help you or rig up support using, for example, the

Triton Multi-Stand.

Try to keep the workpiece moving, even slowly, during

a long rip. Pauses can cause slight steps in the cut. A

finishing cut, removing another 1mm, should help if you

need a completely smooth edge.

Ripping larger sheets

Lock the rip fence firmly with the same reading at both

ends – although you can add 0.5 to 1mm to the rear

fence setting for clearance.

Set the overhead guard as low as possible. Push the

workpiece against the fence and feed gently into the

blade, keeping one hand on either side of the work (Fig

30). Switch off with your thigh when you finish the cut.

For ripping up to 450mm off very large sheets, use

one or two Triton Multi-Stands with a suitable length

of wood clamped in the head(s) to support the offcut

(Fig 31).

For ripping widths greater than 450mm, use the saw

hand-held. Remove the power saw from the table,

remove the trigger strap, and check the operation of

the saw guard. Clamp a guide to the workpiece, which

should be securely supported off the floor on battens

or packers. Never do a freehand cut following a pencil

line; it’s dangerous.

Double ripping

You can double the maximum depth of cut by turning

the wood over, end for end, and making a second cut.

If the blade is exactly square to the table, and if both

edges of the wood are dressed square, the two cuts

should line up (Fig 32).

The overhead guard assembly cannot be fitted for the

first cut, but must be fitted for the second. Ensure your

fingers remain well clear of the blade, even if the wood

‘kicks’ or your hands slip. Use the captive push-stick

and side pressure finger. Make both cuts of similar

depth: for example, cut a 90mm wide piece in 2 cuts of

approx 46mm each.

Saw Fitting

• If a slot you plan to use for your Saw Clamps (13 & 14)

tends to foul an obstruction on the lip of the baseplate,

or the saw motor, or the adjuster controlling the blade

height: use a different slot for the clamp

• If your saw has a very short baseplate: use the four

inner slots. NOTE: The advised 10mm gap between

the blade and the end of the slot in the table insert is a

guide only. You may move the saw a little closer to the

Fig 27

Fig 28

Fig 30

Fig 31

Fig 32