Settings, Step six – tekmar 661 Snow Detector & Melting Control User Manual

Page 5

5

Settings

Step Six

Essential control settings

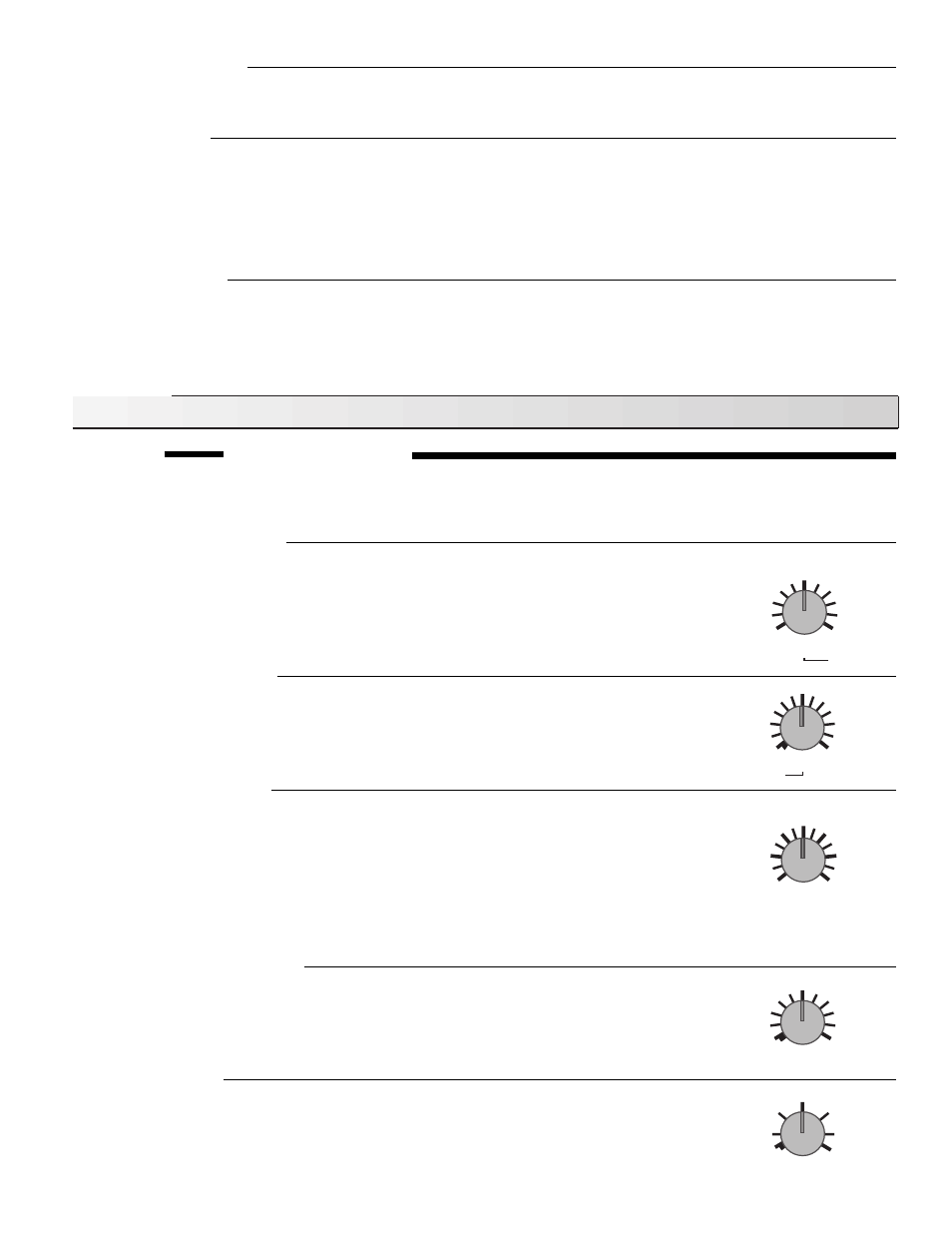

Before adjusting the dial settings, read through the sequence of operation to ensure that you understand how the control oper-

ates. The dials are factory set at the midpoint of each setting. This reflects typical settings for most systems and is therefore a

good starting point.

Sensitivity

50 %

20

80

Melting

Surface

39

°

F

34

44

Melting Surface Temperature

The “Melting” dial setting is the desired slab surface temperature when the control is in melting

mode and is also used as the WWCO temperature. The “Melting” temperature is usually set based

on local weather conditions. In some areas, heavy snow fall can load a slab at temperatures well

above freezing; in these areas the dial should be set higher. If the melting system response is

sluggish, increasing the “Melting” dial setting may cause the system to melt faster, however, it is

important to remember that increasing this setting generally increases energy consumption.

Idling Surface Temperature

The “Idling” dial setting is based on the requirements of the user. If minimizing the time required

for the slab to reach melting temperature is important then the dial is set slightly below freezing

(<32

°

F). If black ice or frost formation is a concern, the dial is set slightly above freezing (>32

°

F).

It is important to remember that increasing this dial setting increases energy consumption. “Idling”

can also be set to “Off”.

Idling

29

°

F

Off

35

24

Surface

Water detection sensitivity

The sensitivity of the Snow/Ice Sensor to water can be adjusted using the “Sensitivity” dial. As

snow becomes contaminated with dirt, and as the sensor surface itself becomes dirty, the control

may incorrectly indicate the presence of water. If this condition occurs, clean the surface of the

sensor and/or turn down the sensitivity setting. If the snow and rain in the area is very clean, the

sensitivity setting may need to be increased before snow is detected.

Minimum On Time

The Minimum On Time setting is primarily used to ensure a minimum operating time regardless

of the Snow/Ice Sensor reading. The built in timer starts counting down once the slab has reached

the “Melting” temperature. If water is detected after the Minimum On Time has elapsed, the control

continues in melting mode until water is no longer detected by the Snow/Ice Sensor.

CWCO (Cold Weather Cut Off)

The “CWCO” temperature is the coldest temperature at which the melting system operates. This

dial is set based on the melting capabilities of the snow melt system and the economics of melting

snow in extreme conditions.

CWCO

0

°

F

-20

25

Off

Min. On Time

2 hrs

4 hrs

Off

0.5

Note: The Snow/Ice Sensor is installed in a hostile environment and should be cleaned on a regular

basis with a wire brush. After cleaning, check operation by pressing the test button to cycle

the control through the test routine.

Test the power supply

• Make sure exposed wiring or terminals are not grounded or in contact with other wires. Turn on the 120 V ac power and,

using an AC voltmeter, you should measure between 110 and 130 V ac at the

Power N – L (5 and 6) terminals.

Test the Outputs

• If a device is connected to the

Melt terminals (1 and 2), make sure power to the device is off and install a jumper between

terminals 1 and 2. When the device is powered-up, it should operate. If it does not turn on, check the wiring from the terminal

plug to the device and refer to any installation or troubleshooting information supplied with the device. If the device is

operating properly, disconnect the power and remove the jumper.

• Repeat this procedure for any devices connected to the

Warning terminals (3 and 4), Pump terminals (7 and 8) and Heat

terminals (9 and 10).

Connect the control

• Turn the power off and make sure all test jumpers have been removed from the plugs.

• Connect the plugs to the control by carefully aligning them with their respective headers and pushing them upwards. The plugs

should snap firmly into the headers.

• Install the supplied safety dividers between the different voltage wiring chambers. Apply power to the control.

• The control is now ready for operation.