Sequence of operation – tekmar 661 Snow Detector & Melting Control User Manual

Page 2

2

IMPORTANT NOTE:

This control requires a Snow/Ice Sensor 090 and Sensor Socket 091. The Snow/Ice Sensor 090 is usually installed

prior to the installation of the control. The installer or designer should plan far enough ahead to allow ample time

for ordering and delivery. The Application Brochures A 661 provide a series of schematics which can be used with

this control. It is important that these applications together with the sequence of operation provided below are fully

understood in order to ensure that the control selected is compatible with its intended use.

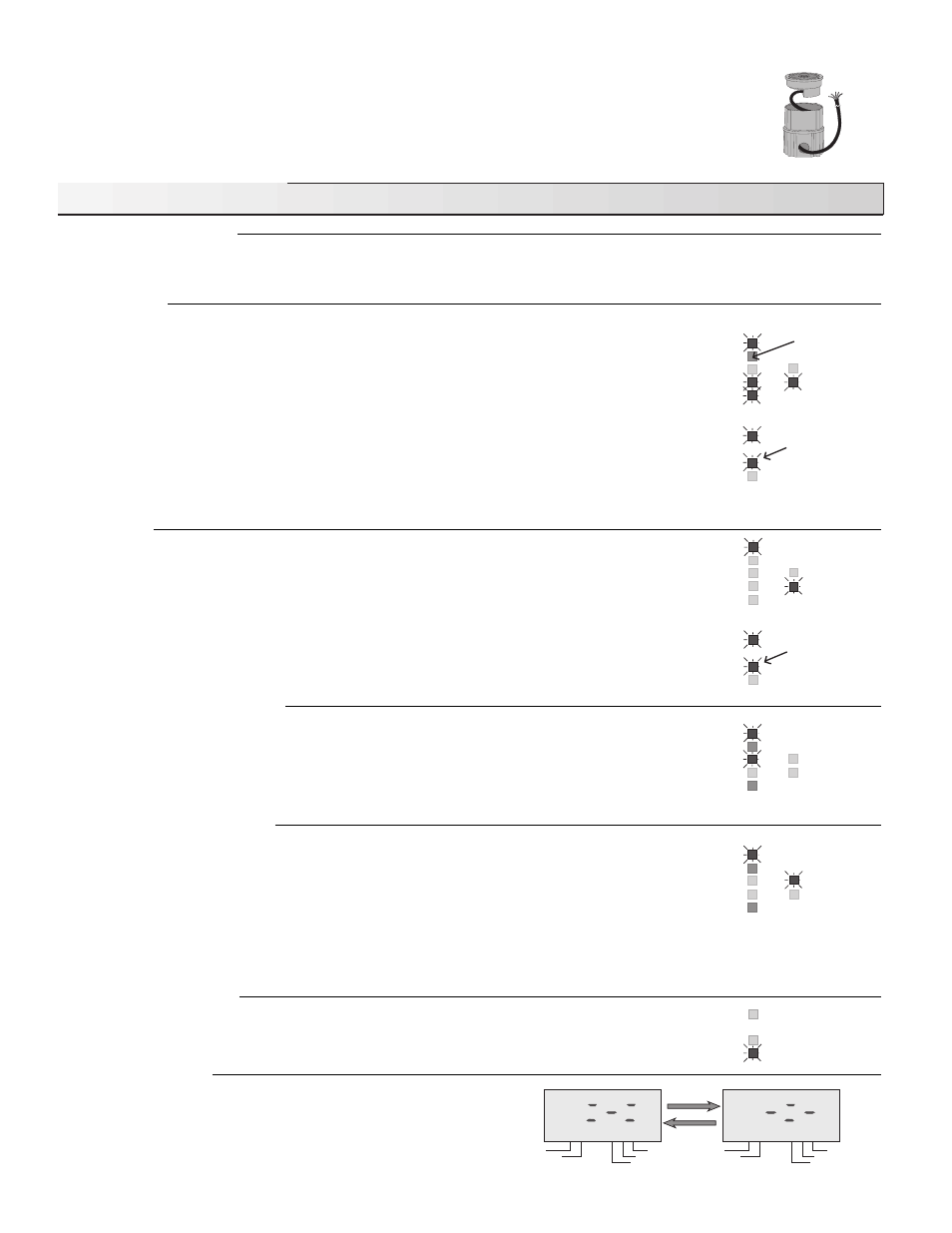

Power

Remote

Pump

Heat

Warning

CWCO

Melting

Idling

WWCO

Water

The heat light

cycles on and off

The remote light is

on if a remote enable

signal is present

Power

Remote

Pump

Heat

Warning

CWCO

Melting

Idling

WWCO

Water

The heat light

cycles on and off

Power

Remote

CWCO

Melting

Idling

WWCO

Water

Power

Remote

CWCO

Melting

Idling

WWCO

Water

Sequence of Operation

Slab

Target Slab

% Output

Usage (hours)

Time Remaining

Slab

Target Slab

% Output

Usage (hours)

Time Remaining

Pump

Heat

Warning

Powering up the control

After the Snow Detector & Melting Control 661 is powered up, the red status lights and the LCD segments are turned on for 7 seconds.

The control then displays the “OUTSIDE” temperature.

Melting Mode

Operation using a Snow/ Ice Sensor 090 - The control continually monitors the Snow/Ice Sensor 090.

When snow, ice or water is detected the water light turns on. If the control is not in WWCO or CWCO

(see below for an explanation of these terms), melting mode begins.

Operation using a Remote Enable - Melting mode can also be initiated if a remote enable signal is

present (terminals Com Sen and Rem Sen shorted together) and the control is not in WWCO or CWCO.

The remote enable is typically used with multiple Snow Melting Controls and Snow/Ice Sensors. It can

also be used to manually turn the melting system on by wiring a switch between the remote terminals.

Once the control is in melting mode, the Pump and Melting lights and the Pump and Melt relays are turned

on for at least the Minimum On Time set by the Min. On Time dial. The Heat relay is cycled on and off

to maintain the slab surface at the “Melting” temperature. The method used to cycle the heat relay is called

Pulse Width Modulation (PWM). More information on PWM is provided in Essay 000.

Idling Mode

When the melting system starts from a cold temperature, the time required for the slab to reach "Melting"

temperature can be excessive. To decrease this start up time, the slab can be maintained at an “Idling”

temperature until melting is required. The Idling feature is also useful for preventing frost and light ice

formation. When the control is in idling mode, control operation is similar to melting mode except the

"Melting" light is off and the "Idling" light is on.

Warm Weather Cut Off (WWCO)

The 661 control can operate with or without an Outdoor Sensor 070. If an outdoor sensor is not used, the

control measures the “Outdoor” temperature using the Edge Sensor on the Snow/Ice Sensor 090. If the

“Slab” and “Outdoor” temperatures rise above the “Melting” temperature, the control shuts down the

melting system and enters Warm Weather Cut Off mode. The control remains in WWCO until the “Outdoor”

temperature drops below the “Melting” temperature. The control then continues with normal operation.

Cold Weather Cut Off (CWCO)

Maintaining the slab at a “Melting” or “Idling” temperature in extremely cold weather can be expensive and

may even be impossible. When it does snow at these colder temperatures, the snow is usually dry, light

and less slippery. The control therefore turns the melting system off when the “Outdoor” temperature

(measured using either the Outdoor Sensor 070 or the 090 Edge Sensor) drops below the “CWCO”

setting. The heater in the Snow/Ice Sensor 090 is kept on during CWCO until the control detects snow.

If snow is detected, the heater is turned off but the control retains the snow detected information. When

the “Outdoor” temperature rises above the “CWCO” temperature, the control exits CWCO and continues

with normal operation.

Warning Light and Relay

If a sensor fault occurs, the warning relay and light are turned on and an error message is given. The

lookup table provided on page 7 can be used to determine which sensor has the fault.

Exercising the pump

To prevent the pump from seizing during long WWCO periods, the

Pump relay is turned on for 20 seconds after every 3 days of no

operation. During exercising, the LCD screen alternates between two

special characters as illustrated in the diagram.