tekmar 356 Mixing Control User Manual

Page 9

Copyright © D 356 -0

9/08

9 of 16

Test The Powered Inputs

Mixing Demand

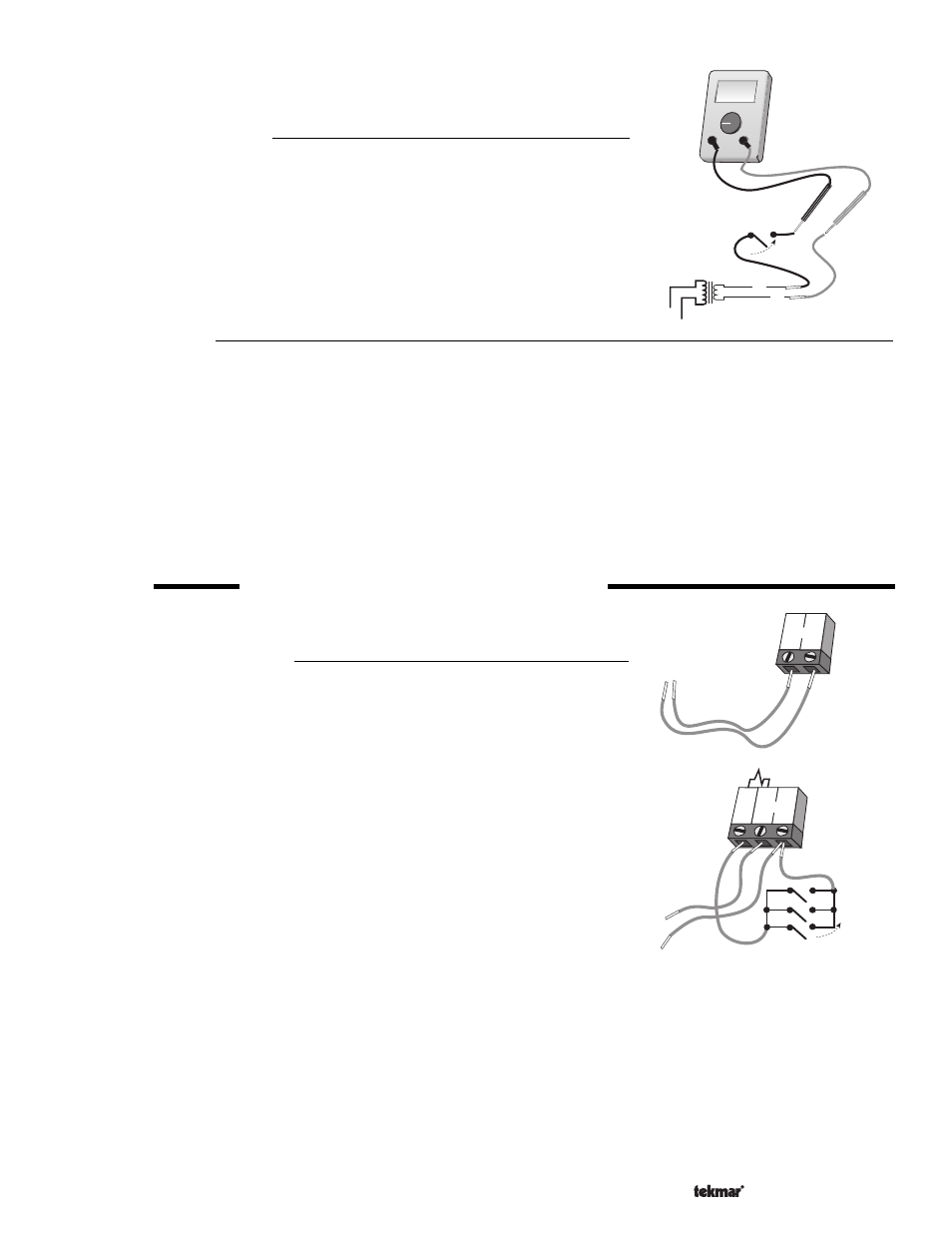

Measure the voltage between the mixing demand wire and the power wire that goes

to R+ of the control. The voltmeter should read between 22 and 26 V (ac) when the

mixing demand device calls for heat.

Test The Outputs

Boiler

Make sure power to the boiler circuit is off and short the boiler wires. When the boiler circuit is powered up, the boiler should fire.

If the boiler does not turn on, refer to any installation or troubleshooting information supplied with the boiler. (The boiler may have

a flow switch that prevents firing until the boiler loop pump is running). If the boiler operates properly, remove power from the

boiler circuit.

Variable Speed Injection Pump

Short the variable speed injection pump wires and power up the pump curcuit; the variable speed pump should operate at full

speed. If the pump does not operate, check the wiring, and refer to any installation or troubleshooting information supplied with

the pump. If the pump operates properly, remove the power from the variable speed injection pump circuit.

STEP FIVE

ELECTRICAL CONNECTIONS TO THE CONTROL

The installer should test to confirm that no voltage is present at any of the wires.

Powered Input Connections

24 V (ac) Power

Connect the 24 V (ac) power supply to the

Power R+ and Power C- terminals (8 and

9). This connection provides power to the microprocessor and display of the control.

Mixing Demand

To generate a mixing demand, terminal

T(7) must be connected to terminal C-(9)

through a switching device.

24 V (ac)

Class II

Transformer

C

R

Ω

V

V

Mixing demand

switch

24 V (ac)

C-

Power

R+

8

9

C-

T

Power

R+

7

8

9

Mixing demand switches

24 V (ac)