Dip switch setting, Output connections boiler contact, Variable speed injection pump – tekmar 356 Mixing Control User Manual

Page 10: Sensor and unpowered input connections, Outdoor sensor, Boiler sensor, Mixing sensor, Advanced / installer

Copyright © D 356 -0

9/08

10 of 16

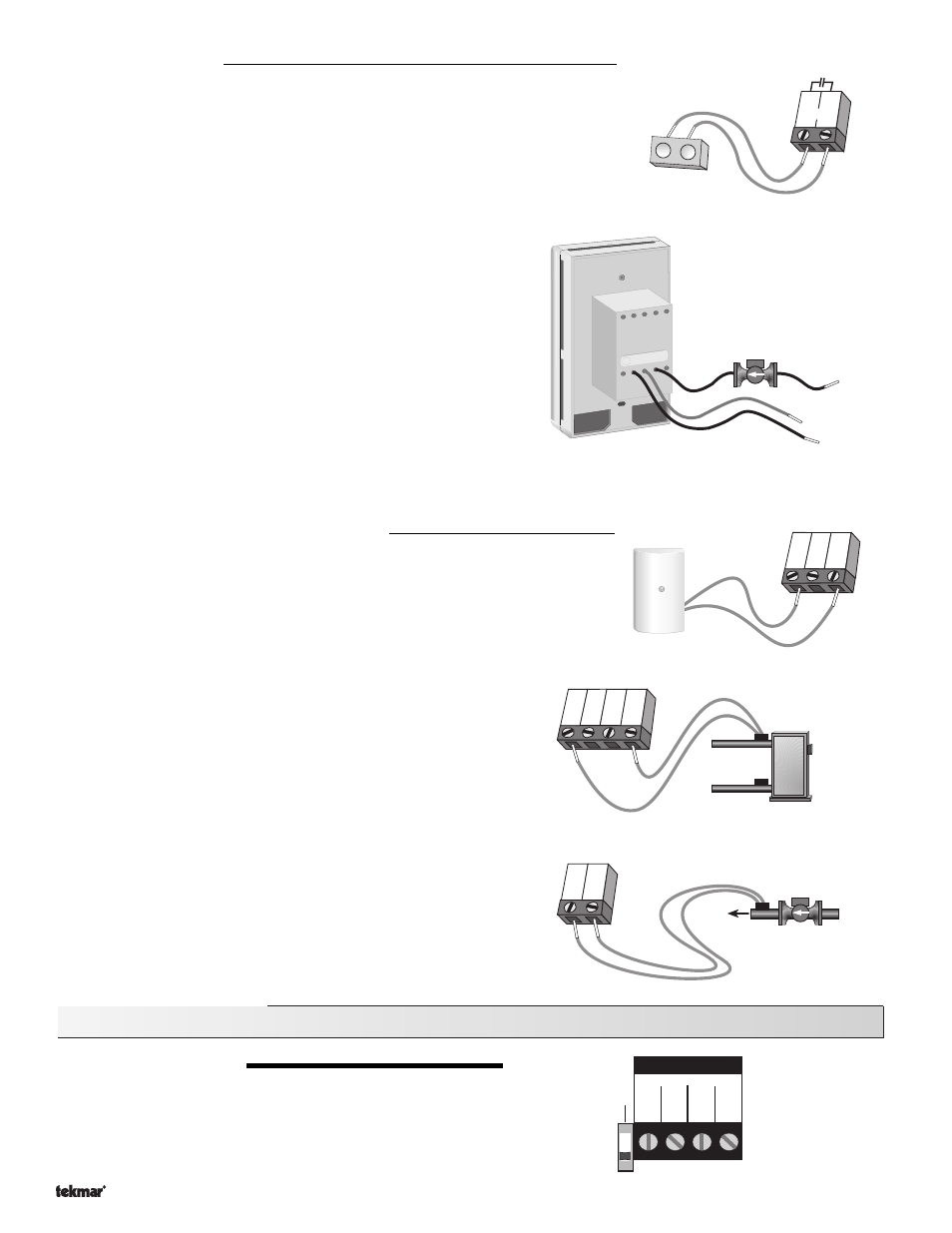

Output Connections

Boiler Contact

The

Boiler terminals (5 and 6) are an isolated output in the 356. There is no power

available on these terminals from the control. These terminals are to be used as a

switch to either make or break the boiler circuit. When the 356 requires the boiler to

fire, it closes the contact between terminals 5 and 6.

Variable Speed Injection Pump

The 356 can vary the speed of a permanent capacitor, impedance

protected, or equivalent pump motor that has a locked rotor current

of less than 2.4 A. Most small wet rotor circulators are suitable as

described in Essay E 021. The 356 has an internal overload pro-

tection circuit which is rated at 2.5 A 250 V (ac). Contact your tekmar

sales representative for details on the repair procedures if this cir-

cuit is blown.

Connect one of the wires from the variable speed injection pump to

one of the black wires from the back of the control. Connect the

second black wire from the back to the live (L) side of the 120 V

(ac) power source. The other wire on the variable speed injection

pump must be connected to the neutral (N) side of the 120 V (ac)

power supply. Connect the green wire on the back of the control to

ground.

Sensor and Unpowered Input Connections

Do not apply power to these terminals as this will damage the control.

Outdoor Sensor

Connect the two wires from the Outdoor Sensor 070 to the

Com and Out terminals (1

and 3). The outdoor sensor is used by the 356 to measure the outdoor air tempera-

ture.

Boiler Sensor

Connect the two wires from the Boiler Sensor 071 to the

Com and

Boil terminals (1 and 4). The boiler sensor is used by the 356 to

measure the boiler temperature.

Mixing Sensor

Connect the two wires from the Mixing Sensor 071 to the

Com and

Sup terminals (1 and 2). The mixing sensor is used by the 356 to

measure the supply water temperature after the variable speed

injection pump. Normally the sensor is attached to the pipe down-

stream of the system pump.

DIP Switch Setting

ADVANCED / INSTALLER

The

Advanced / Installer DIP switch is used to select which items are

available to be viewed and / or adjusted in the user interface.

T

T

T

T

Boiler

5

6

STOP

Refer se

rvicing to

qualified

personnel. O

pening vo

ids

warranty

.

Ground

(green)

Pump

(black)

120 V or L

(black)

N

Sup

Out

2

3

Com

1

Boiler return

sensor

or

Boiler supply

sensor

Boil

Sup Out

2

3

4

Com

1

Mixing

sensor

Sup

Com

1

2

System

pump

Inst/Adv

Do not apply power

Com Sup Out Boil

1

2

3

4