tekmar 356 Mixing Control User Manual

Data brochure, D 356, Mixing control 356

Copyright © D 356 -09/08

1 of 16

- Data Brochure

Mixing Control 356

D 356

09/08

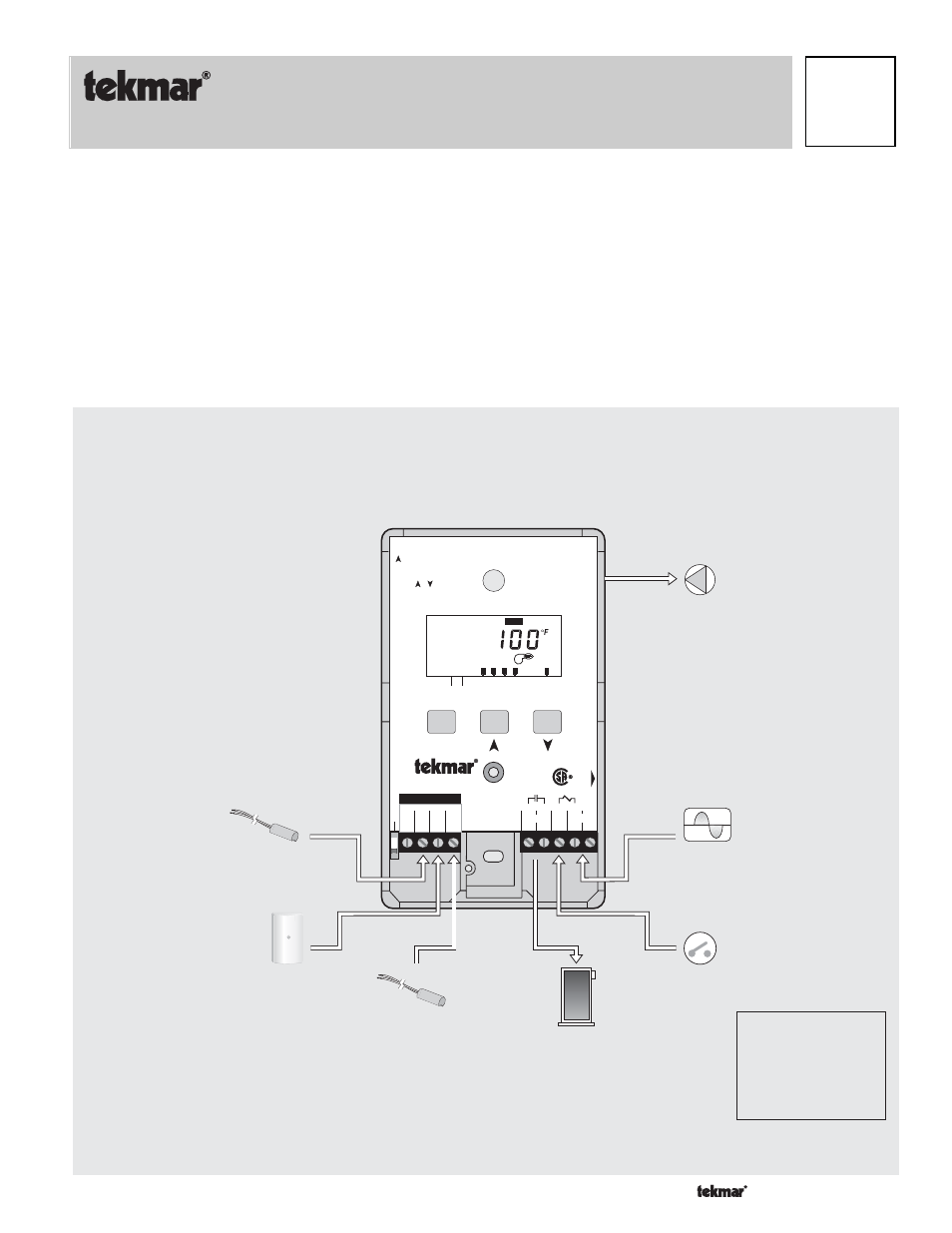

The Mixing Control 356 is designed to control the supply water temperature to a hydronic system in order to provide outdoor reset or

setpoint operation. The control uses a variable speed injection pump to regulate the supply water temperature, while protecting the

boiler against flue gas condensation. The control has a Liquid Crystal Display (LCD) to view system status and operating information.

Additional functions include:

• Quick Setup for easy installation and programming of control

• User comfort adjustment to increase or decrease building

space temperature

• Advanced settings to fine-tune building requirements

• Boiler Control for improved energy savings

• Test sequence to ensure proper component operation

• CSA C US certified (approved to applicable UL standards)

Mixing Control 356

Variable Speed

Input

Outdoor Sensor

Included

Input

Supply Sensor

Included

Input

24 V (ac)

Power Supply

Output

Boiler

Input

Boiler Sensor

Included

Inst/Adv

Do not apply power

Com Sup Out Boil

R+ C-

T

C US

Press & Release

Item + + , to adjust menu

Made in Canada

Signal wiring

must be rated

at least 300 V

Press & Hold

Item, to view settings

, to test

Power:

Var. Pmp:

Relay:

H1

193C

Terminal Unit

24 V ±10% 50/60 Hz 3 VA

120 V (ac) 2.4 A 1/6 hp

120 V (ac) 5 A 1/6 hp

Mixing

Demand

10 30 50 70 90

Return Supply

% Out

Mixing Control 356

Variable Speed

Input

Mixing Demand

Signal

Output

Variable Speed

Injection Pump

(through back

of control)

1

2

3

4

5

6

7

8

9

VIEW

Item

MIX

Boiler

Power

tektra 911-02

Meets Class B:

Canadian ICES

FCC Part 15

Dat

e Code

Note:

Mix demand must have an

electrical closure between

terminals 7 and 9 before the

mix injection pump is able

to operate and the boiler

is able to fire.