tekmar 265 Boiler Control User Manual

Page 6

©

2010 D

265

-

07/10

6

of

36

Section B1: Boiler Modulation

Section B: Boiler Operation

EXERCISING

The control has a built-in exercising feature that is selected through the Exercise / Off DIP switch. To enable the exercising feature set

the Exercise / Off DIP switch to Exercise. If exercising is enabled, the control ensures that each pump is operated at least once every

3 days. If a pump has not been operated at least once every 3 days, the control turns on the output for 10 seconds. This minimizes

the possibility of the pump seizing during a long period of inactivity. While the control is exercising, the Test LED flashes quickly.

Note: The exercising function does not work if power to the control or pumps is disconnected.

FACTORY DEFAULTS

The control comes preset with several factory defaults. These defaults are based on the terminal unit selection (see section C).

To fine-tune building requirements, these defaults may be changed.

To reload the factory defaults listed in the ADJUST Menu, power down the control and wait for 10 seconds. Power up the control

while simultaneously holding the Menu and

▼ buttons. An E01 error occurs forcing the installer to go through the ADJUST menu

to ensure the settings are correct.

MODULATION

The control provides three modulating output signals, three boiler enable contacts, and three boiler pumps contacts to operate up

to three modulating boilers. The boiler enable contact may not be required, depending on the make and model of the boiler(s).

The control operates a boiler by first closing the boiler pump contact. The boiler enable contact is closed next and then the control

provides a modulating output signal to the boiler.

The modulation output signal is then modulated from the minimum modulation using Proportional, Integral and Derivative (PID)

logic in order to satisfy the boiler target temperature.

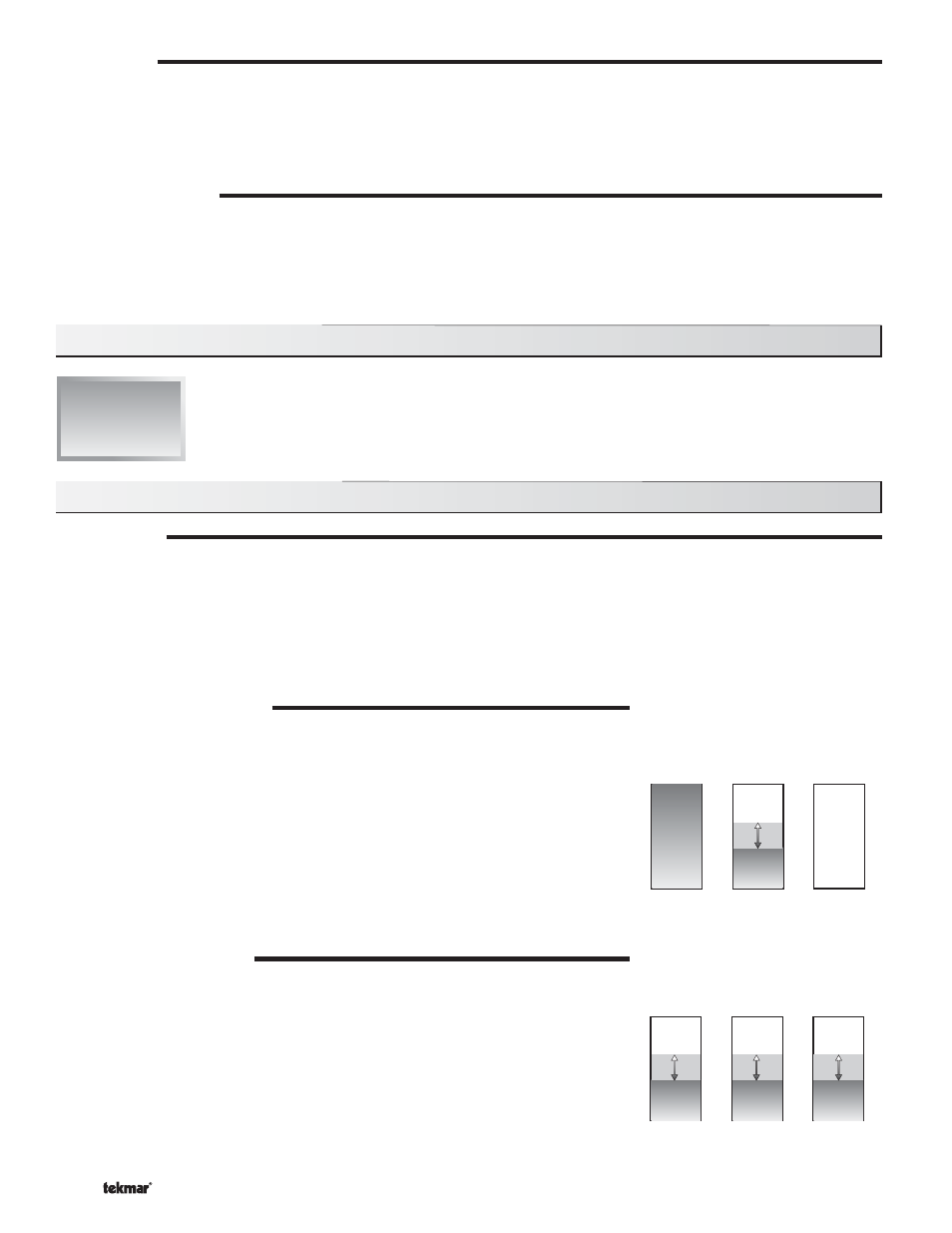

SEQUENTIAL MODULATION

Boiler 1

Boiler 2

Boiler 3

100%

MOD

OFF

PARALLEL MODULATION

Boiler 1

Boiler 2

Boiler 3

MOD

MOD

MOD

SEQUENTIAL MODULATION

The control offers a sequential modulation option. This is selected by setting the

Sequential / Parallel DIP switch to Sequential. Sequential modulation should be used on

boilers that are more efficient when operating at high fire.

In sequential modulation, the first boiler is turned on and is modulated to satisfy light loads.

Once the first boiler does not have enough capacity to satisfy the load, the first boiler

reduces its modulation to provide a smooth transition when the second boiler fires at low

fire. The first boiler then modulates up to maximum modulation as the load increases. Only

then is the second boiler able to increase its output as the load continues to increase.

When the third boiler is required, the second boiler reduces its modulation to allow the

third boiler to operate at low fire. As the load continues to increase, the second boiler is

modulated to its maximum and then the third boiler is modulated. The operation is reversed

when shutting off the boilers.

PARALLEL MODULATION

The control offers a parallel modulation option. This is selected by setting the

Sequential / Parallel DIP switch to Parallel. Parallel modulation should be used on boilers

that are more efficient when operating at low fire.

In parallel modulation, the first boiler turns on at low fire and begins to increase its

modulation. Once the first boiler’s output is greater than the combined output of the first

and second boiler’s low fire, the first boiler is modulated down to low fire and the second

boiler is fired at low fire. The two boilers now modulate together. Once the two boiler’s

combined output is greater than the combined output of all three boilers operating at low

fire, the first and second boilers are modulated down to low fire, and all three boilers are

operated at low fire. The boilers are then modulated as the load increases. The operation

is reversed when shutting off the boilers.

Section B1

Boiler

Modulation