Overview, 5 control mode selection – Banner EZ-ARRAY USB Serial Adapter User Manual

Page 6

4

P/N 126701

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

A-GAGE EZ-ARRAY

QuickStart Guide

Overview

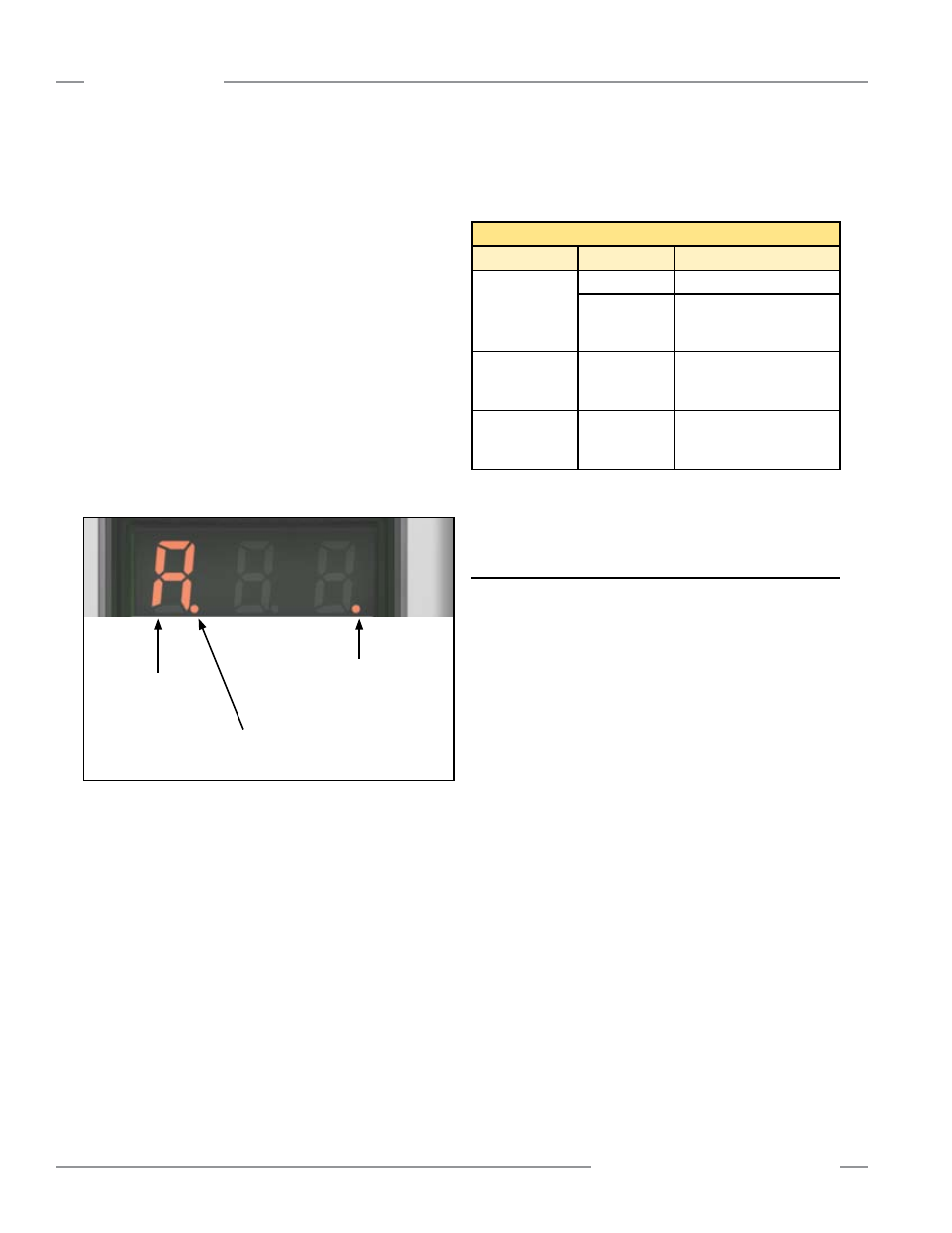

Three-Digit Display

The 3-digit display has slightly different functions during

normal operation, alignment, and gain adjust modes. In normal

operation the display indicates current numerical value of the

measurement mode for analog output 1. The display also

identifies the following activated sensor functions: blanking and

locked-out user interface/electronic configuration, as shown in

Figure 1-4. (For information on inverting the display, see Section

4.4 or 5.)

During blanking mode, the display reads “n”, followed by the

number of blocked beams in the array. During alignment mode, it

reads “A”, followed by the number of blocked, unblanked beams;

a period follows the A (“A.”) if blanking is configured.

During gain adjust mode, the display reads “

l

” followed by “1” or

“2” to indicate the gain level. (A “1” represents high excess gain,

and a “2” represents low contrast.)

If a sensing error occurs, the display reads “c” followed by a

number that corresponds to the recommended corrective action

(see Section 4.6).

Blanking Indicator

The Blanking indicator will be visible (ON) whenever the user

has enabled the blanking feature. It appears as a period

following the first digit of the display.

Electronic Configuration Indicator

The Electronic Configuration indicator is ON when the sensor

configuration is not defined by the receiver interface, but by

the GUI (this is set via the GUI). When electronic configuration

is enabled, the receiver interface DIP switch and push button

settings are ignored.

Figure 1-4. Indications provided by the 3-digit display

1.5 Control Mode Selection

The control mode determines the method used to control

scanning of the light screen array. Choose from two control

modes: continuous scan mode and gate mode (which itself has

four options). Continuous scan is automatically selected when

the receiver interface is used for configuration.

In Continuous Scan Mode, the receiver begins a new scan as

soon as it updates the outputs from the previous scan. This is

the fastest scan control method; it is used in most analog output

applications and whenever continuous updating of the outputs is

acceptable. It is available via either the receiver interface or the

GUI.

Gate Mode can be selected via the GUI only. It uses the

receiver Teach (gray) wire to provide a gate input pulse from

(typically) a dc device, such as an NPN-output photoelectric

sensor or a PLC discrete output. Refer to Section 5 for more

information.

Gate mode has four options:

• Gate ON: the receiver will scan as long as the gate is active.

• Gate OFF: the receiver will scan whenever the gate is not

active.

• Gate rising edge: the receiver will scan once for each gate

transition from falling edge to rising edge.

• Gate falling edge: the receiver will scan once for each gate

transition from rising edge to falling edge.

Receiver Interface Status Indicators

LED Indicator

Color

Explanation

System Status

Green

System is OK

Red

Marginal Alignment or

Hardware Error;

check 3-digit display*

Modbus

Activity

Yellow ON or

Flashing

Activity detected on the

modbus communication

channel

Modbus Error

Red

Communication Error:

Check cabling or modbus

master controller

* Display shows “

c”: See Section 4.6.

Display shows only numbers: Low Gain/Marginal Alignment

condition. See Section 4.6.

Receiver Interface Status Indicators

The receiver has three status indicators: green/red System

Status, yellow Modbus Activity, and red Modbus Error. The

following table lists the indicator states.

Period ON indicates

Blanking Configured

‘A’ in this

position indicates

Alignment mode

Period ON indicates

Electronic Configuration

Enabled