Installation, 4 optical alignment – Banner EZ-ARRAY USB Serial Adapter User Manual

Page 20

18

P/N 126701

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

A-GAGE EZ-ARRAY

QuickStart Guide

Installation

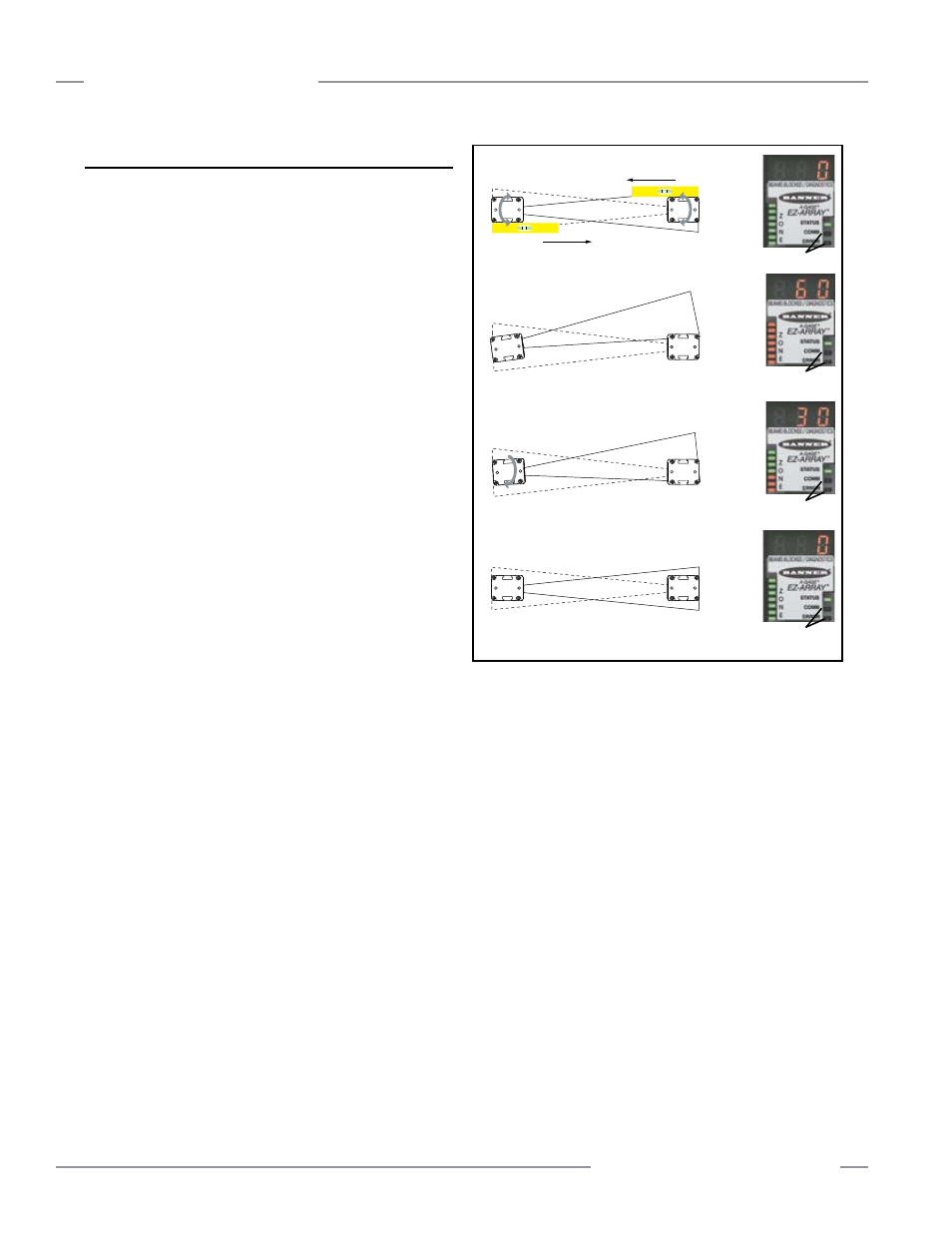

3.4 Optical Alignment

After the electrical connections are made, power up the emitter

and receiver. Verify that input power is present to both emitter

and receiver; the emitter Status indicator and the receiver Status

LED should be ON green. If the receiver Status LED is on red

(and a “c” appears on the 3-digit display), refer to Section 4.6.

NOTE: At power-up, all Zone indicators are tested (flash

red), then the number of blocked beams is displayed.

Observe the receiver indicators.

Possible Indicator Combinations

The 3-digit display shows the number of blocked beams

Zone indicator(s) red: beams in that zone blocked (not

blanked)

Zone indicator(s) green: all beams in that zone made or

blanked

• Aligned and Clear (Run) condition – the receiver Status

indicator and Zone indicators all ON green. The 3-digit display

reads 0.

• Partial Alignment – the receiver Status indicator remains ON

green. Some Zone indicators are red to designate areas where

the beams are not made (are out of alignment or blocked).

The 3-digit display reads the number of blocked/mis-aligned

beams.

• Out of Alignment – the receiver Status indicator remains ON

green. All Zone indicators are red, to designate that some

beams are blocked in each zone. The 3-digit display reads the

total number of beams in the array.

Optimize Alignment and Maximize Excess Gain

Verify that the emitter and receiver are pointed squarely

at each other. A straightedge (e.g., a level) can determine the

direction the sensor is facing (see Figure 3-7).

Slightly loosen the sensor mounting screws and rotate one

sensor to the left and right, noting the positions where the

receiver Zone indicators turn from green to red; repeat with the

other sensor. Center each sensor between the noted positions

and tighten the end cap mounting screws, making sure to

maintain the positioning. The sensor windows should directly

face each other.

Once optimum optical alignment is verified, proceed to

configuration, via the receiver interface, the remote teach wire

or the GUI (Section 4.2 or 5 of the full manual) and complete

the electronic alignment. This further alignment step adjusts the

emitted light level of each beam for the application, to complete

the alignment process.

Figure 3-7. Optimizing optical alignment; 300 mm model shown

Straightedge

Straightedge

a)

b)

c)

d)

OFF

OFF

OFF

OFF

0 beams blocked; all Zone indicators ON Green

60 beams blocked; all Zone indicators ON Red

30 beams blocked; 4 Zone indicators ON Green, 3 ON Red

0 beams blocked; all Zone indicators ON Green