Overview – Banner EZ-ARRAY USB Serial Adapter User Manual

Page 4

2

P/N 126701

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

A-GAGE EZ-ARRAY

QuickStart Guide

Overview

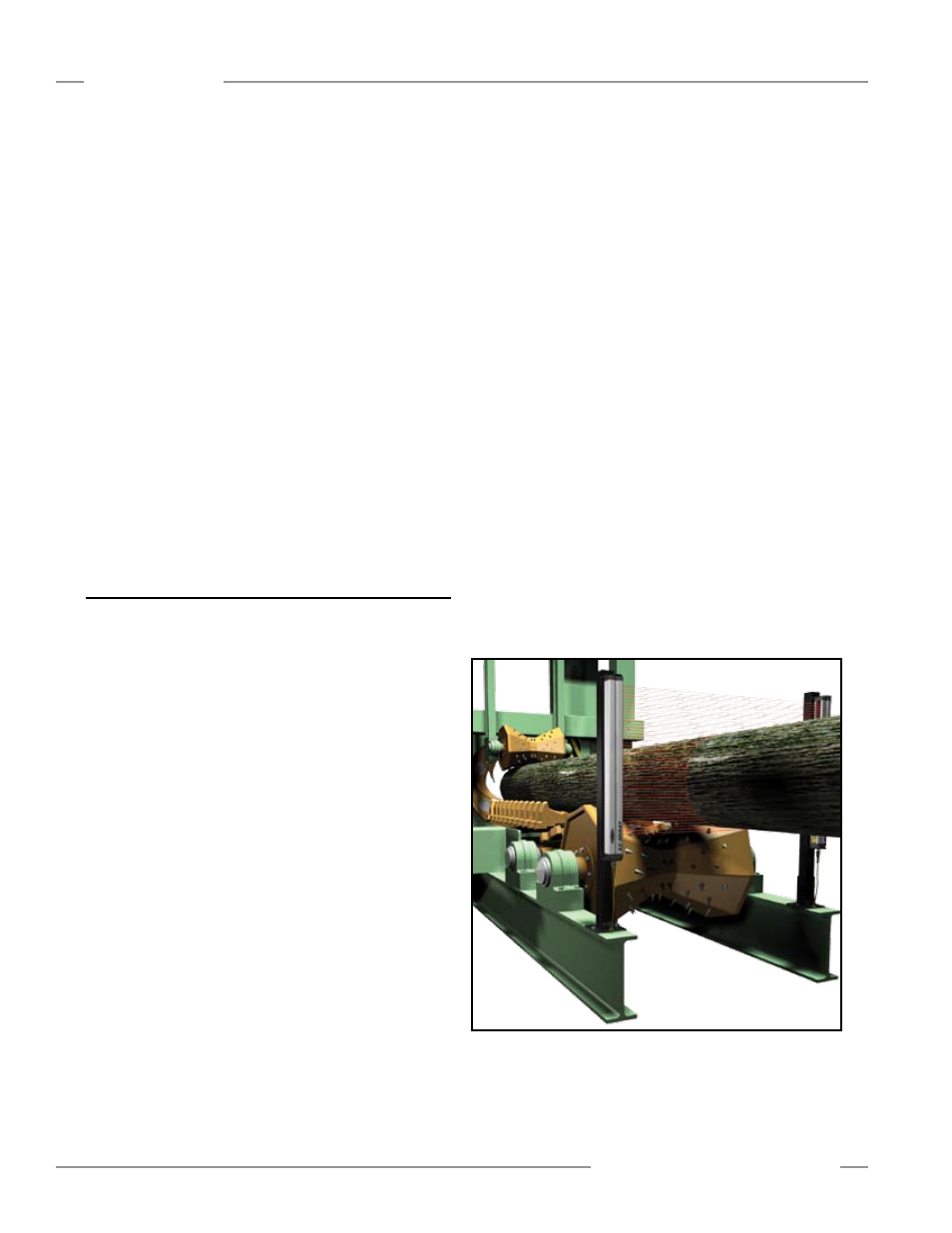

Figure 1-2. A typical A-GAGE EZ-ARRAY application

The emitter has a red LED that signals proper operation (ON

when power is applied). See Section 1.4 for more information

about indicators and Section 4.6 for display codes and

troubleshooting.

The Alignment routine (Section 4.2, or Section 5 of the full

manual) automatically equalizes the excess gain of each beam

for reliable object detection throughout the array. The Alignment

routine need not be performed again unless the sensing

application changes, or if the emitter and/or receiver is moved.

Programmable beam blanking accommodates machine

components or other fixtures that must remain in or move

through the light screen. Blanking may be set using the receiver

interface, the teach wire or the GUI.

The EZ-ARRAY light screen provides a wide selection of

sensing and output options, including measurement (“scan

analysis”) modes and scanning methods that can determine

a target object’s location, overall size, total height, or total

width, or the number of objects. Scanning may be continuous

or controlled by a gate sensor. Up to 15 systems may be

networked, via modbus; see Section 5 or Appendix A of the full

manual.

1.2 Configuration via DIP Switch or Supplied Software

Commonly used configuration options can be set up easily via

a six-position DIP switch located behind a hinged clear access

panel on the front of the receiver.

Access to the DIP switch can be prevented by using the screw-

on security plate to hold the clear access panel closed or by

disabling them via the GUI.

For more individualized (advanced) applications, the supplied

GUI software program (which runs on a PC-compatible

computer running Windows

®

XP or 2000; see Section 5 of the

full manual for more information) may be used to configure the

receiver. The menu-driven program walks the user through the

many scanning and output options. After the desired options are

selected, the combination of selections can be saved in an XML

file, stored in the system configuration computer and recalled as

needed.

The software also provides alignment and diagnostics routines.

An Alignment screen displays the individual status of each beam

in the light screen, as well as the total number of beams, and

totals of beams blocked, made and blanked. Built-in diagnostics

can be used to assess emitter and receiver hardware errors.

(See Section 5.)

Outputs

All models have two analog outputs and two discrete outputs. An

additional serial output communicates to the PC via a modbus

RTU-485 interface.

The analog outputs are either 4–20 mA current or 0–10V voltage,

depending on model (see Section 2-1). They may be configured

(via DIP switch or software) for either a positive or negative

slope.

Discrete output 2 is selectable (via DIP switch or software) for

alarm or measurement operation. When the receiver interface is

used, discrete output 1 follows the operation of analog output 1

(it conducts when the analog output senses a target is present).

When the GUI is used for configuration, both discrete outputs

have full configurability, including measurement mode, NPN or

PNP polarity, and normally open or normally closed operation.

Gain Setting

The receiver can be set for either high-excess-gain or low-

contrast operation, depending on the quality of the sensing

environment, necessary sensing range and the opacity of the

sensed target (see Section 4.3). For low-contrast operation, only

a portion of each beam must be blocked for detection to occur.

Display Invert

For applications where the sensors must be inverted (and thus

the display is not right-reading), the receiver offers a display

invert feature, which inverts the diagnostic display for easy

reading (see Section 4.4).