Splicing – CommScope BOSTM BrightPath Optical Solutions User Manual

Page 32

Splicing

The following instructions are general practice for fusion splicing. Refer to the instructions that came with the splicer

on how much buffer to strip, recommended cleavers and other specifics.

Prepare the distribution upstream fiber

Find the midpoint of the fiber to be spliced into the tap module.

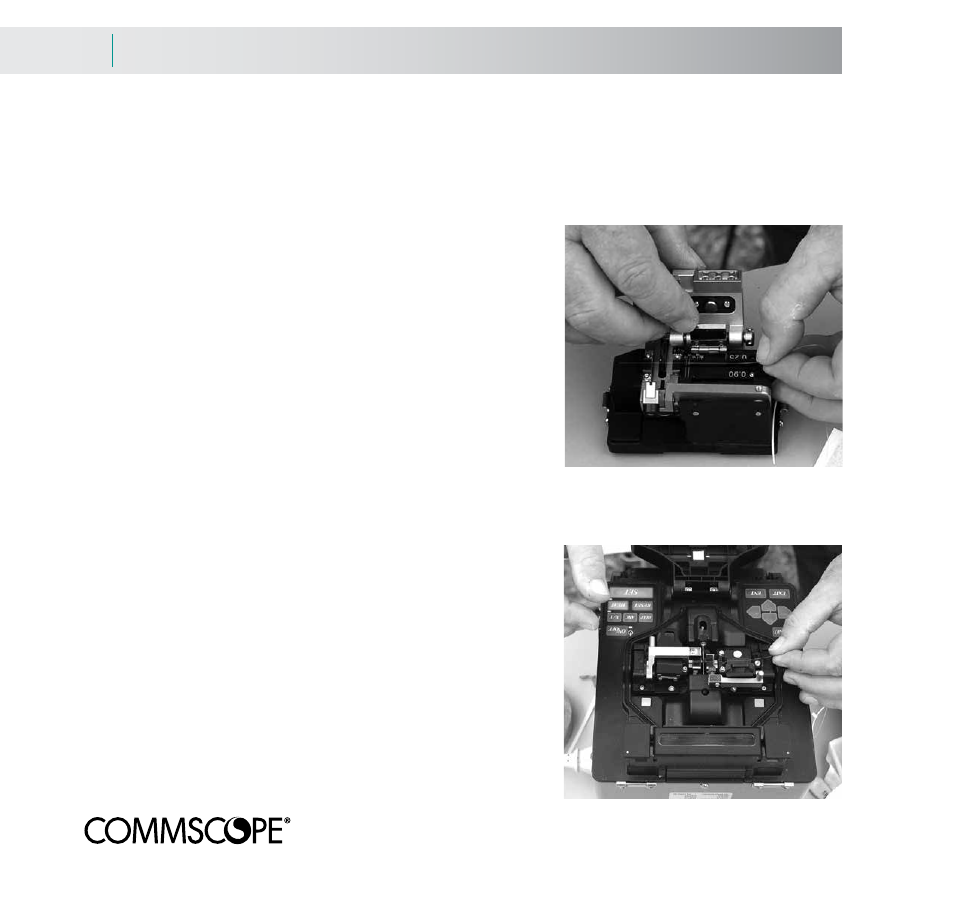

Use the fiber cleaver to cut the selected fiber at the midpoint. Place the

splice protection sleeve over the upstream end of the fiber and let it

slide toward the buffer tube.

Use the fiber stripper to remove the fiber buffer. Clean the fiber with a

lint-free cloth soaked in 95 - 97% isopropyl alcohol to remove the buf-

fer residue. Avoid touching the bare fiber.

Use the fiber cleaver again to achieve a perpendicular face for the

fiber.

Prepare the tap upstream fiber

Strip, clean and cleave the optical tap’s upstream/input fiber (with the “I” tag) using the method above. Place both

fiber ends into the splicer and initiate the splice sequence.

Splice the fibers together

The splice should have a loss of no more than 0.04 dB. If the loss is

higher, cut the fiber and repeat the splicing process.

Position the sleeve

Once the fiber is successfully spliced, place the splice protection sleeve

over the splice and activate it. Most sleeves use a heat-shrink plastic

reinforced with a metal rod. (The unit shown has an integrated sleeve

heater shown at the bottom of the photo).

Repeat the process with the downstream fiber

Splice the tap module’s downstream/output fiber (with the “O” tag) to

the remaining fiber segment using this same technique.

8.4 Optical Tap Installation

Splicing