Line monitoring and output states, Housekeeping, Fault detection/testing – Rockwell Automation T8449 Trusted TMR 24V dc Valve Monitor Module - 40 Channel User Manual

Page 11: Table 1 line monitoring fault status, Trusted, Module t8449

Trusted

TM

Module T8449

Issue 13 Apr 10

PD-T8449

11

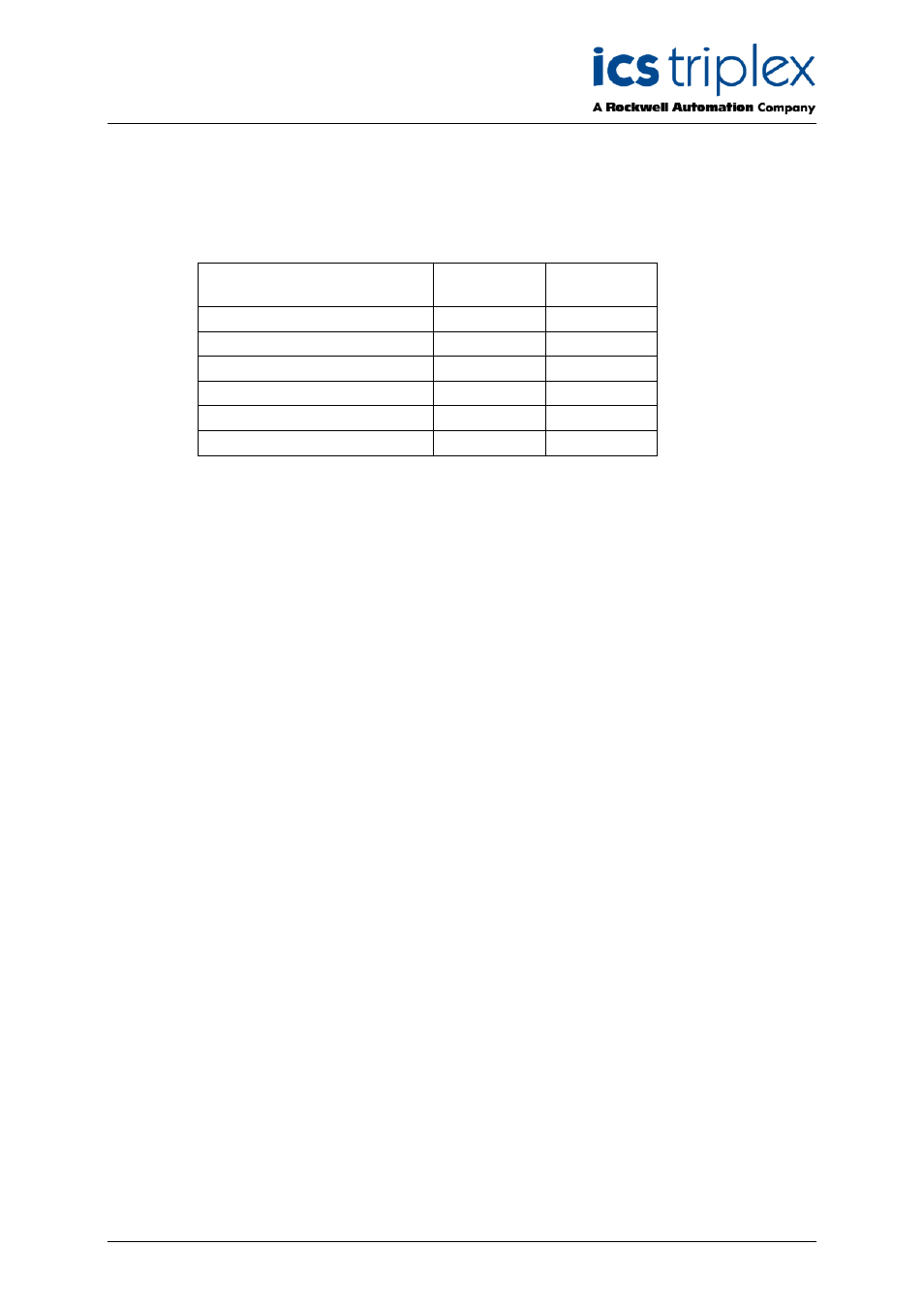

1.5. Line monitoring and output states

The module automatically monitors the control output channel current and voltage to determine the

state of the output channel. The numerical output state and line fault status reported back to the

application is represented below.

Description

Numerical

Output State

Line Fault

Status

Field Fault

6

1

Field Short Circuit

5

1

Output Energised (On)

4

0

No Load, Field Open Circuit

3

1

Output De-energised (Off)

2

0

No Field Supply Voltage

1

1

Table 1 Line Monitoring Fault Status

The Field Fault condition is used to report cases where the output is commanded De-energized (Off),

but voltage is being supplied to the output circuit through some external source.

Default threshold values used for non line monitored inputs are as follows (in raw units)

Default = 1000, -1000, 3000, 3000, 5000, 5000, 7000, 7000

1.6. Housekeeping

The output module automatically performs local measurements of several on-board signals that can be

used for detailed troubleshooting and verification of module operating characteristics. Measurements

are made within each slice’s HIU and FIU.

1.7. Fault Detection/Testing

Extensive diagnostics provide the automatic detection of module faults. The TMR architecture of the

output module and the diagnostics performed ensure the validity of all critical circuits. Using the TMR

architecture provides a Fault Tolerant method to withstand the first fault occurrence on the module and

continue normal output controls without interruption in the system or process. Faults are reported to

the user through the Healthy status indicators on the front panel of the module and through the

information reported to the TMR Processor. Under normal operations all three Healthy indicators are

green. When a fault occurs, one of the Healthy indicators will be flashing red. This indicates that the

module should be replaced.

Module replacement activities depend on the type of spare module configuration chosen when the system was

configured and installed. The module may be configured with a Dedicated Standby Slot or with a SmartSlot for a

spare replacement module.

From the IMB to the field connector, the I/O module contains extensive fault detection and integrity

testing. As an output device, most testing is performed in a non-interfering mode. Data input from the

IMB is stored in redundant error-correcting RAM on each slice portion of the HIU. Received data is

voted on by each slice. All data transmissions include a confirmation response from the receiver.

Periodically, the TMR Processor commands the onboard DSPs to perform a Safety Layer Test. The

SLT results in the DSP verifying with the TMR Processor its ability to process data with integrity. In

addition, the DSP uses Cyclical Redundancy Checks (CRC) to verify the variables and configuration

stored in Flash memory.